The Rise of Engineered Plastics: How High-Performance Materials Are Transforming Key Industries

Over the last decade, some of the most advanced industries in the world have undergone a quiet yet powerful revolution—not in the products they build, but in the materials they use to build them. Sectors such as Aerospace & Defense, Medical, Oil & Gas, and Optical technologies are increasingly moving away from traditional metal components in favor of engineered plastics—high-performance polymers designed to meet the toughest industrial demands.

This shift is more than just material substitution. It’s a strategic move toward lighter, more durable, more chemically resistant, and more cost-effective alternatives that often outperform metals in critical applications. As industries evolve to meet stricter performance, environmental, and economic standards, engineered plastics are quickly becoming the material of choice.

Why Engineered Plastics?

At first glance, metals like steel, aluminum, and titanium seem unbeatable in terms of strength and reliability. But they come with drawbacks—weight, susceptibility to corrosion, complex manufacturing processes, and often higher costs. In contrast, high-performance plastics offer:

Weight reduction without compromising strength

Resistance to corrosion and harsh environments

Design flexibility for complex geometries

Lower lifecycle costs due to minimal maintenance needs

Chemical resistance ideal for high-risk environments

Biocompatibility for medical applications

As material science has advanced, so too has the range and capability of these plastics. Today’s polymers can meet strict aerospace tolerances, function within the human body, and withstand the corrosive environments of offshore drilling platforms.

Let’s explore how these materials are reshaping four key industries.

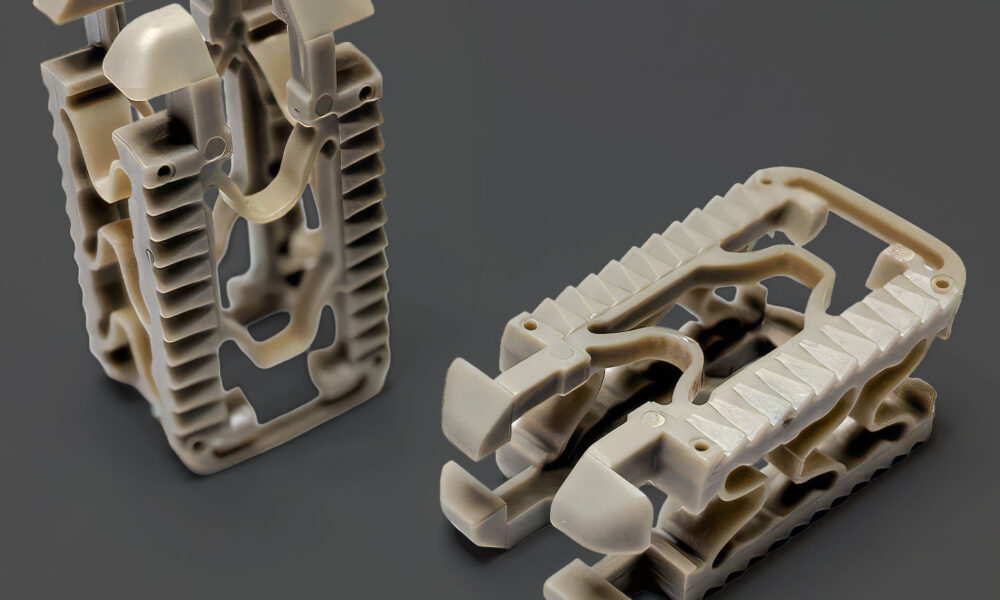

Aerospace & Defense: Lighter, Stronger, More Resilient

In aerospace, weight is everything. Every additional pound increases fuel consumption and operating costs. By replacing metal components with high-performance plastics such as PEEK (Polyetheretherketone) and PTFE (Polytetrafluoroethylene), aerospace engineers are achieving significant weight reductions without sacrificing durability.

These polymers are now used in:

Insulation for cabling and electronics

Bearings and seals in moving parts

Structural elements in lightweight composite assemblies

What makes these materials stand out isn’t just their weight—they resist corrosion, function in extreme temperatures, and don’t require the same maintenance routines metals do. This is especially valuable for defense systems and aircraft that operate in unpredictable, often hostile environments.

In an industry where every ounce of performance matters and safety is non-negotiable, engineered plastics are proving indispensable.

Medical: Safe, Sterile, and Affordable Innovation

In the medical field, the stakes are equally high. Devices must be not only strong and functional, but biocompatible—safe to be used in or near the human body. Here, high-performance plastics like polycarbonate, PEEK, and Ultem are leading the charge.

They are now found in:

Surgical instruments that must withstand repeated sterilization

Implantable devices such as spinal cages and joint replacements

Diagnostic housings and handheld scanners

Unlike metal alternatives, engineered plastics can be molded into complex, ergonomic shapes, sterilized repeatedly, and remain chemically stable under exposure to bodily fluids or hospital-grade disinfectants. Their cost-effectiveness also allows manufacturers to create high-precision, disposable instruments without compromising quality.

As healthcare providers balance cost pressures with the demand for safer, more sophisticated devices, engineered plastics deliver on both fronts.

Oil & Gas: Built for the Extreme

Few industries present as punishing an environment as oil and gas. From deep sea pressures to high-temperature chemical exposure, components used in exploration and refining must endure the worst.

Traditionally, metal was the only choice. Today, that’s changing.

Plastics like PVDF (Polyvinylidene fluoride) and PEEK are increasingly used in:

Valve seats and seals

Pipe liners

Pump components and gaskets

These materials offer exceptional resistance to chemical corrosion, thermal degradation, and abrasion, often outperforming metal in harsh environments. Their lighter weight also simplifies transportation and installation—particularly valuable for offshore operations.

Because they don’t rust, degrade, or require frequent replacement, engineered plastics reduce downtime and maintenance costs, which translates into major operational savings over time.

Optical: Precision Meets Performance

The optical industry may not operate under the same extreme conditions as aerospace or oil rigs, but it has its own set of challenges—particularly the need for precision and durability in small, delicate components.

Optical devices often involve complex geometries and miniaturized assemblies. High-performance plastics like Ultem, PEEK, and PTFE are ideal for:

Molded lens housings

Sensor mounts

Optical fiber guides and protective covers

These materials offer superior dimensional stability, impact resistance, and the ability to be precisely molded at scale. In consumer electronics, wearables, and industrial optics, this translates to lighter, more user-friendly devices that require less maintenance.

Additionally, their resistance to moisture and chemicals makes them ideal for environments where clarity and longevity are essential.

A Broader Push Toward Sustainable Efficiency

Beyond their individual benefits in each sector, the shift to engineered plastics reflects a larger trend across all high-performance industries: the pursuit of efficiency, sustainability, and innovation.

Lighter materials reduce energy consumption, especially in transport and aerospace.

Corrosion resistance extends service life, minimizing waste and the need for replacements.

Manufacturing efficiency lowers the carbon footprint of production.

Design freedom enables new innovations not possible with traditional metal forming.

As regulations tighten and global demands for sustainable manufacturing increase, engineered plastics offer a way forward that doesn’t compromise performance.

Looking Ahead

The future of manufacturing and engineering will be shaped by what we choose to build with—and engineered plastics are poised to be at the heart of that evolution.

From the skies above to the ocean floors, from surgical suites to smart glasses, these materials are enabling faster innovation, longer-lasting products, and better outcomes.

Industries that embrace this material revolution will find themselves better positioned to meet the challenges of tomorrow—lighter, faster, stronger, and smarter.