The Role of High-Performance Plastics in Gaskets, Seals, and Poppets

In the world of industrial manufacturing, gaskets, seals and poppets may seem like small components—but their significance is immense. They perform critical functions, including sealing joints, minimizing vibration, and preventing leaks across a wide range of industries such as Oil & Gas, Fluid Management, and HVAC. At Pexco, we specialize in designing and molding these parts with advanced high-performance thermoplastics, offering technical solutions that outperform traditional materials in demanding applications.

Why Material Selection Matters

Choosing the right material for gaskets, seals, and poppets is not just a matter of cost—it’s a matter of performance and reliability. These components must maintain their function under extreme operating conditions, and selecting an inadequate material can result in premature failure, unplanned downtime, or even safety hazards.

Several factors must be considered when determining the best plastic for the application:

- Temperature Resistance: The material must tolerate the full operational temperature range without losing integrity.

- Pressure Resistance: It must sustain the pressure conditions of the environment without deformation or breakdown.

- Corrosion Resistance: Exposure to aggressive chemicals or fluids shouldn’t cause degradation.

- Mechanical Properties: Flexibility, tensile strength, low density, and adhesion capabilities are critical.

- Regulatory Compliance: Adherence to both product-specific and industry-wide standards ensures operational safety and consistency.

The Advantage of High-Performance Plastics

A high-performance plastic is defined by its ability to meet stringent criteria often required in place of metals. Characteristics include:

- High strength and durability

- Resistance to high temperatures

- Superior electrical insulation

- Low friction and lightweight profile

- Chemical resistance

- Excellent machinability and moldability

Pexco works extensively with advanced polymers such as PEEK, PFA, FEP, Torlon, and Ultem. These materials offer superior performance compared to traditional metal components and provide customizable features for specific application needs.

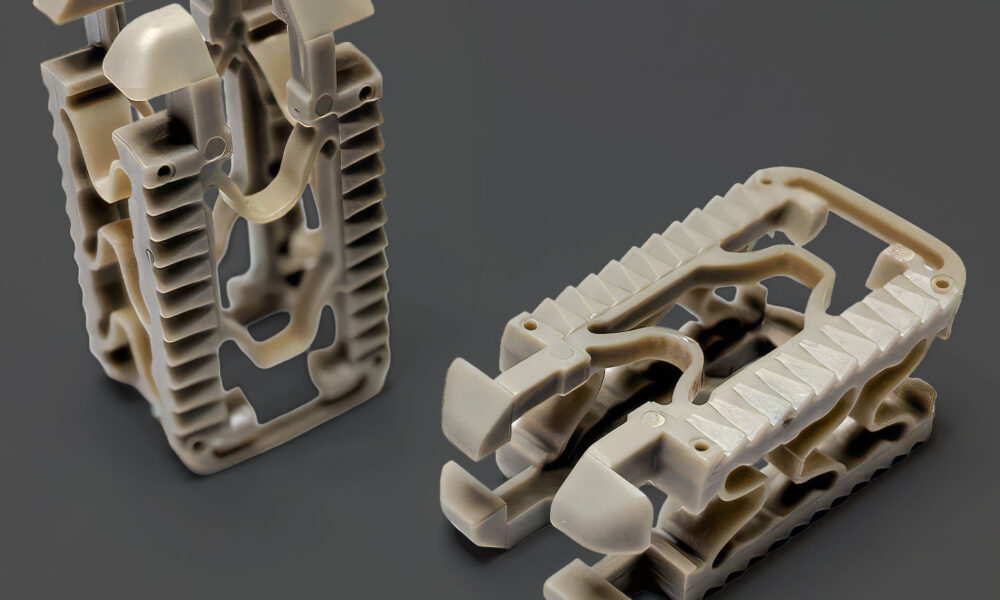

Gaskets: Sealing and Beyond

A gasket functions as a mechanical seal that fills the space between two or more mating surfaces, preventing leakage under compression. Traditionally made from metal or rubber, high-performance plastic gaskets now provide a lighter, more durable, and more corrosion-resistant alternative.

Key advantages of plastic gaskets include:

- Improved sealing and insulation

- Enhanced resistance to chemicals

- Reduced friction and wear

- Lower weight and easier handling

- Customizability for complex geometries and thin-walled designs

These properties make plastic gaskets ideal for industries that require tight dimensional tolerances and high durability over extended lifecycles.

Advanced Capabilities Backed by Experience

With over 60 years of experience in molding advanced thermoplastics, Pexco offers deep knowledge and an unwavering commitment to quality. We’ve worked with clients across a spectrum of industries, delivering solutions that align with their technical and operational demands.

We also integrate industrial CT scanning into our process to provide unmatched precision in measurement science. This enables us to validate that gaskets, seals, and poppets meet every dimensional and functional requirement, ensuring long-term performance in the field.

Serving Critical Industries

Our materials and engineering capabilities are well-suited for use in:

- Oil & Gas: Resistance to pressure, temperature, and chemicals is crucial.

- Fluid Management: Superior sealing and chemical resistance ensure system integrity.

- HVAC: High durability and temperature tolerance reduce maintenance and extend product life.

Every application has its own unique set of challenges—and we meet those with tailored material recommendations, tight-tolerance manufacturing, and end-to-end quality assurance.

Let’s Engineer Better Together

Whether you’re seeking to replace a metal component, improve performance, or reduce costs, Pexco offers a powerful combination of materials knowledge, design support, and manufacturing excellence. Our collaborative approach means we’ll help you every step of the way—from design validation and material selection to final production.

For more information on Pexco’s Injection Molding & Extrusion capabilities,

please request information at pexco.com/contact-us.