Designing with PEEK in Semiconductor Manufacturing

What is PEEK?

When it comes to high-performance materials for semiconductor design, few polymers can compete with PEEK — Polyether Ether Ketone. Designers in the semiconductor industry face constant challenges: creating components that withstand high heat, aggressive chemicals, and ultra-clean environments, all while maintaining dimensional stability. PEEK has emerged as one of the rare materials that can deliver on all these demands.

This article explores the design implications of PEEK for semiconductor equipment and wafer manufacturing, detailing not only its material properties but also how they translate into practical advantages for engineers and designers.

What Makes PEEK Unique

At its core, PEEK is a semi-crystalline thermoplastic. Its molecular structure is composed of repeating phenylene rings and oxygen bridges, which provide both rigidity and flexibility at the microscopic level. This unique architecture delivers several hallmark properties:

- High mechanical strength: PEEK resists wear, making it ideal for moving parts.

- Thermal stability: It can endure sustained use at temperatures up to 260°C without degradation.

- Chemical resistance: It is virtually impervious to harsh solvents and acids, including hydrofluoric acid, a standard chemical in chip manufacturing.

- Low outgassing: Essential for maintaining ultra-clean semiconductor environments.

- Dimensional stability: Even after extended cycles of heat and chemical exposure, PEEK maintains tight tolerances.

For designers, this means PEEK can be reliably incorporated into systems where most plastics — and even metals — fail.

The Role of PEEK in Wafer Manufacturing

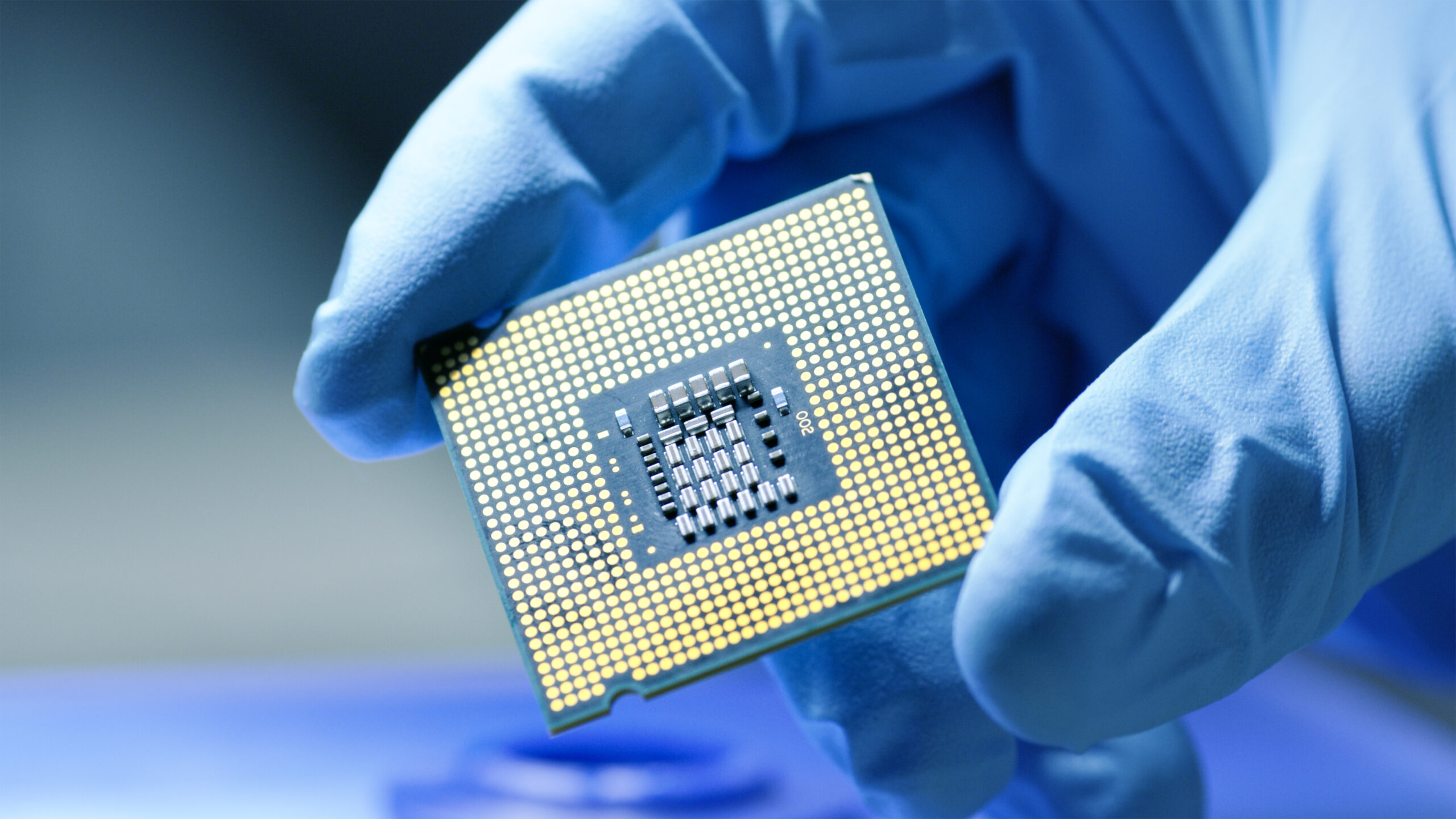

Wafer manufacturing is the foundation of semiconductor fabrication. It involves building integrated circuits layer by layer onto a silicon wafer through a series of deposition, etching, doping, and polishing steps. Each stage demands absolute precision and material integrity.

From CMP (Chemical Mechanical Polishing) rings to fluid manifolds and fasteners in wet benches, PEEK has become a go-to design material. The stakes are high: even the smallest particle contamination or dimensional drift can reduce yields and drive up costs.

By incorporating PEEK, designers can build equipment that:

- Runs longer without downtime

- Reduces the risk of contamination

- Handles aggressive processing conditions with greater efficiency

Design Advantages of PEEK

1. Extending Component Lifetime

One of the most immediate advantages designers see with PEEK is its wear resistance. CMP rings, a critical component in polishing wafers, endure constant friction. Traditional materials degrade quickly, leading to frequent replacement cycles.

- PEEK CMP rings demonstrate up to 2x longer wear life compared to conventional materials.

- Longer life translates directly into less downtime for maintenance and higher throughput for wafer fabs.

Design Insight: When specifying PEEK for CMP rings, designers can reduce dimensional overbuild since wear rates are lower. This allows tighter tolerances and less wasted material.

2. Improving Wafer Yields

Yield is king in semiconductor manufacturing. Even a 1% improvement can save millions annually. A major source of yield loss is contamination from processing equipment itself — particles, outgassed chemicals, or impurities leaching into the environment.

- PEEK’s low particle generation ensures fewer contaminants.

- Its high purity and low extractives minimize outgassing.

- The result: a cleaner process and higher wafer yield.

Design Insight: Designers can optimize flow paths, fastener placement, and sealing surfaces using PEEK, knowing it won’t compromise yield.

3. Speeding Up Processing Cycles

Semiconductor fabs operate under immense pressure to shorten cycle times. Every stage that can be accelerated without compromising quality increases production capacity.

- PEEK withstands temperatures up to 260°C, allowing processes to run hotter and faster.

- Its chemical resistance means it can endure aggressive cleaning and etching without requiring long, gentle cycles.

- Less need for cooling translates into faster turnaround times.

Design Insight: By incorporating PEEK, designers can push equipment toward leaner, high-throughput cycles, reducing bottlenecks in wafer production.

Practical Applications of PEEK in Semiconductor Equipment

PEEK is not just a theoretical material. Designers are already using it in diverse semiconductor applications, from structural components to micro-precision fittings.

CMP Rings

PEEK’s hardness and wear resistance make it an excellent material for CMP rings, where dimensional integrity and longevity are paramount.

Fasteners in Wet Benches

Chip manufacturing frequently uses hydrofluoric acid, a highly corrosive chemical. Metals corrode quickly, compromising assemblies and contaminating processes.

- PEEK screws and bolts resist corrosion.

- They maintain strength even after long exposure to acids.

- They preserve the clean environment due to low outgassing.

ICU Production Components

During ICU (integrated circuit unit) manufacturing, PEEK fasteners provide a high-purity alternative to metal, ensuring reliable long-term assembly in critical areas.

Fluid Manifolds and Handling Components

Fluid management in semiconductor production requires dimensionally stable, chemically resistant materials.

- PEEK manifolds maintain tight tolerances even under high pressure and temperature.

- They support complex geometries through CNC machining or molding, giving designers flexibility in system architecture.

Design Considerations When Working with PEEK

While PEEK offers many advantages, designers must understand its behavior and limitations to get the most from it.

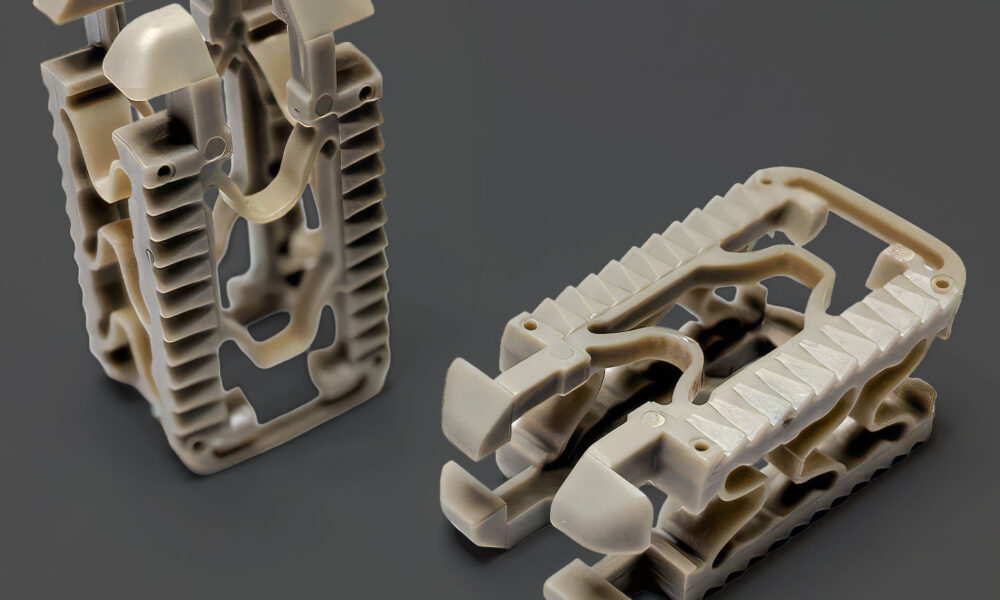

1. Machining vs. Molding

- Machining: PEEK machines well and supports high-precision tolerances, making it ideal for prototypes and low-volume production.

- Molding: Injection molding is best for high-volume components, though tooling costs are higher.

Tip: Consider hybrid workflows — CNC machining for small runs and injection molding for mass production.

2. Thermal Expansion

PEEK has a different Coefficient of Thermal Expansion (CTE) than metals. In hybrid assemblies, differential expansion can stress joints.

Tip: Use floating fasteners or design flexible joints to accommodate expansion mismatches.

3. Surface Finishing

Particle shedding must be minimized. Post-machining polishing or coating may be required for CMP parts or any component exposed directly to wafers.

4. Integration with Other Materials

While PEEK can replace metals, sometimes it works best in combination. For example, metal-PEEK hybrids balance strength with chemical resistance.

Tip: When combining with metals, carefully design interface geometries to account for stress and avoid crevice corrosion.

Beyond Function: PEEK as a Design Enabler

For designers, PEEK is not just a substitution for failing materials — it’s a design enabler. Its unique combination of properties allows new forms, tighter tolerances, and more aggressive process strategies that simply aren’t possible with other materials.

Some examples of design opportunities:

- Thinner-walled manifolds without sacrificing strength

- More compact CMP rings with longer life cycles

- Lightweight fasteners that outperform metal in corrosive environments

- Modular fluid handling systems that remain chemically stable under varying conditions

By considering PEEK early in the design process, engineers can redefine equipment capabilities rather than simply extending existing designs.

Expertise and Collaboration

Implementing PEEK into semiconductor design requires not just material knowledge, but also expertise in machining, molding, and finishing. Performance Plastics’ engineering team offers deep experience in this area.

- Complex component design: CMP rings, manifolds, seals, and fasteners

- Prototyping and scale-up: From single components to mass production

- Application-specific solutions: Tailored designs for aggressive semiconductor environments

For designers, working with specialists means reduced trial-and-error, faster development cycles, and components that meet the rigorous demands of the fab floor.

Need Help Selecting the Right Material?

For designers working in semiconductor manufacturing, PEEK is more than just a material — it’s a strategic advantage. Its combination of chemical resistance, thermal stability, wear performance, and purity make it uniquely suited for wafer fabrication and related applications.

By embracing PEEK, designers can:

- Extend component lifetimes

- Improve wafer yields

- Accelerate processing cycles

- Expand design possibilities

In an industry where precision, purity, and performance define success, PEEK provides the foundation for innovation at the material level.

For more information on Pexco’s Injection Molding & Extrusion capabilities, please request information at pexco.com/contact-us.