Our Products

Our Brands

Markets

Capabilities

About Pexco

Seals, Gaskets, and Bushings

At Pexco, we specialize in manufacturing seals, gaskets, poppets, and bushings from high-performance fluoropolymers (PFA, FEP, PTFE, and filled PTFE), thermoplastics (PEEK, Torlon®, and Ultem™), and elastomers (EPDM, Neoprene, Nitrile, Silicone, and SBR). These components are essential in industrial applications—sealing joints, reducing vibration, preventing leaks, and enhancing system integrity. Our materials expertise and advanced manufacturing capabilities result in components that seal better, last longer, and offer improved cost-efficiency.

Functional Overview

Seals

Mechanical seals are engineered to close off the openings between system components, containing pressure and preventing fluid leakage (e.g., water, oil) to the external environment. They are critical in pumps, motors, compressors, and other equipment to ensure reliable, efficient operation.

Gaskets

MechanicPolymer gaskets create a tight seal between two surfaces to block the passage of gases or liquids and protect against contamination. Known for their durability, chemical resistance, and low friction, they are widely used across industries and ideal for applications requiring static sealing.

Bushings (Bearings)

Also referred to as bearings, polymer bushings reduce friction and wear between moving parts. They provide support, alignment, and shock absorption while offering benefits such as corrosion resistance, low friction, and self-lubrication—making them suitable for diverse industrial environments.

Precision-Engineered for Demanding Applications

Seals, gaskets, and bearings—especially those interfacing with moving parts—must meet exacting standards for fit, durability, and reliability. These components often operate under intense pressure, heat, and mechanical stress, and require:

- Mechanical strength, thermal stability, and chemical resistance

- Tight dimensional tolerances

- Exceptional surface finish

- Material consistency and structural integrity

Pexco’s proprietary processes enable dimensional tolerances as tight as 0.003 inches, ensuring superior performance and longevity across both dynamic and static applications.

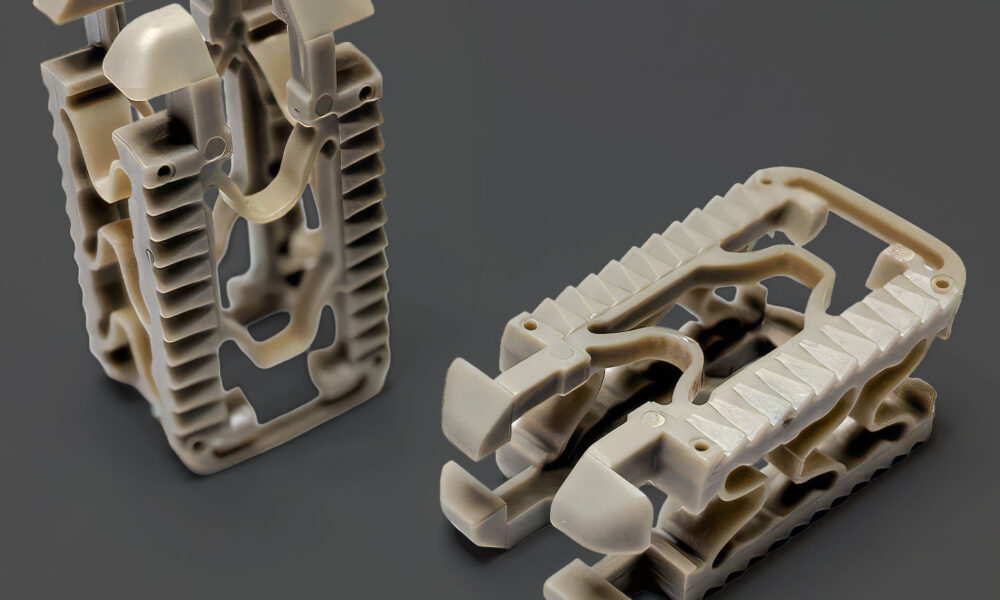

Net Shape Molding for Superior Mechanical Properties

Our Net Shape Molding process is optimized for polymer-based seals, gaskets, and bearings. This advanced injection molding technique minimizes material waste and eliminates voids, sink marks, and porosity—resulting in stronger, more reliable parts with uniform mechanical properties.

- Enables high-volume, repeatable production

- Ensures consistent quality with minimal post-processing

- List Item

Custom Extruded Elastomers for Tailored Performance

Seals and gaskets made from extruded elastomers must deliver consistent performance under compression, flexing, and environmental exposure. Whether used in static or dynamic applications, these components must maintain their sealing integrity over time and across a range of application factors including varying temperature requirements, UV and ozone exposure, chemical resistances, and mechanical strains and stresses. To meet these demands, they require:

- Application-driven material chemistries and properties (durometer, physical properties, weathering, and other exposures)

- Tight control over wall thickness, ID/OD, and cross-sectional geometry

- Compatibility with regulatory and industry standards (ASTM, UL, ISO, FDA, etc.)

At Pexco, we work closely with customers to develop extruded solutions tailored to their specific design and performance requirements. Whether the application calls for dense or sponge elastomers or TPEs, we offer a broad range of materials to meet demanding customer applications – available in cord, tubing, and custom profile extrusions.

Key Applications Include:

Air Compressors

Oil seals are designed to pressurize the seal area above process gas pressure, enhancing leak prevention.

Static Interfaces

Gaskets fill surface irregularities between mating parts to ensure a complete seal.

Rotational Systems

Bearings maintain alignment and reduce wear under heavy loads and harsh conditions.

From Print to Production

A Scalable Manufacturing Partner for Every Stage of Product Development

At Pexco, we understand that no two product journeys are the same — and neither are their manufacturing requirements. Whether you’re in the early stages of design or preparing to scale for high-volume production, Pexco provides the engineering expertise and manufacturing flexibility to meet your needs every step of the way.

Many of our customers begin with a concept or engineered drawing — a detailed print that defines form, fit, and function. Our team works closely with yours to evaluate material requirements, tolerances, environmental conditions, and performance goals.

If initial volumes are low, our precision machining capabilities allow us to quickly and accurately produce parts to spec. This is ideal for prototyping, pilot runs, or low-rate initial production where flexibility and speed are critical.

Pexco produces cord, tubing, and complex profile extrusions in a wide range of dense and sponge materials, tailored to dimensional and performance requirements. This process is ideal for high-flexibility parts, continuous lengths, and designs that demand material-specific performance under challenging conditions.

As your program evolves and demand increases, Pexco can seamlessly transition to scalable production methods — including custom injection molding — to drive down per-part cost, improve cycle time, and ensure consistency at high volumes.

As your program evolves and demand increases, Pexco can seamlessly transition to scalable production methods — including custom injection molding — to drive down per-part cost, improve cycle time, and ensure consistency at high volumes.

What sets Pexco apart is our ability to support the full product lifecycle:

- Standard shapes for fast-turn stock applications

- Precision machining for prototypes, development, or small-run production

- Custom extrusion for complex geometries and specialty polymer and elastomer requirements

- Injection molding for high-volume, repeatable manufacturing

At Pexco, we understand that no two product journeys are the same — and neither are their manufacturing requirements. Whether you’re in the early stages of design or preparing to scale for high-volume production, Pexco provides the engineering expertise and manufacturing flexibility to meet your needs every step of the way.

From concept to scale, Pexco is your trusted partner for precision plastic components.

Seals, Gaskets, and Bushings

Request More Information

Have a question or need a quote? Our team is ready to help with product specifications, custom requirements, and technical support.

"*" indicates required fields