Our Products

Our Brands

Markets

Capabilities

About Pexco

Pexco Capabilities

Advanced Plastic Engineering

Where Ideas Take Shape

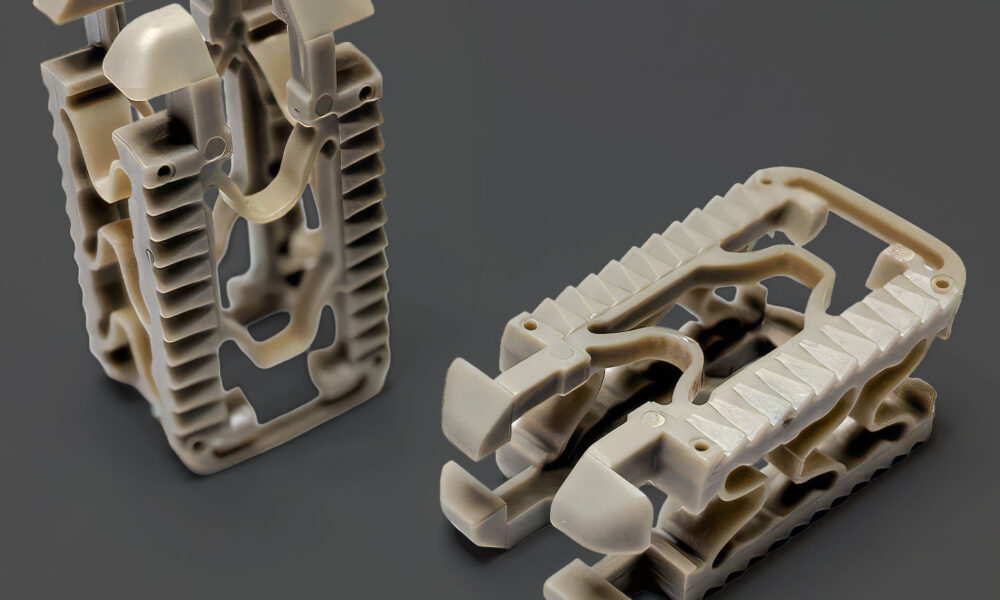

Pexco’s Advanced Plastic Engineering division provides the technical infrastructure for manufacturing complex plastic components across North America. With 6 in-house tool and die centers, proprietary vacuum calibration systems, advanced metrology capabilities, and comprehensive design engineering services, we engineer solutions from initial concept through high-volume production.

Our engineering capabilities deliver the technical precision required for demanding applications in aerospace, medical devices, semiconductor equipment, and industrial systems.

Engineering Capabilities

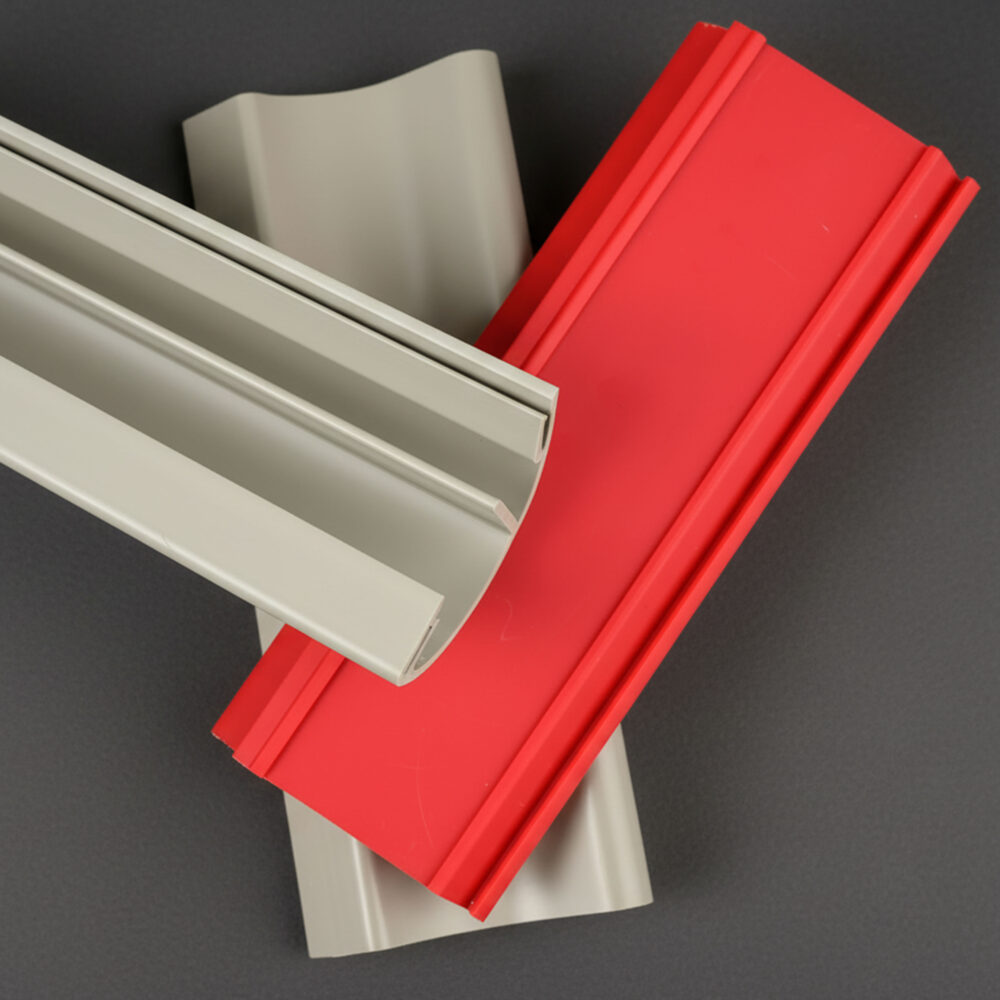

Vacuum Calibration Technology

Precision dimensional control for large-scale and complex extruded profiles. Our house-built vacuum calibration systems deliver exceptional tolerances and repeatability for profiles up to 30″+ wide, including multi-chamber hollow cross-sections that cannot be achieved through conventional sizing methods.

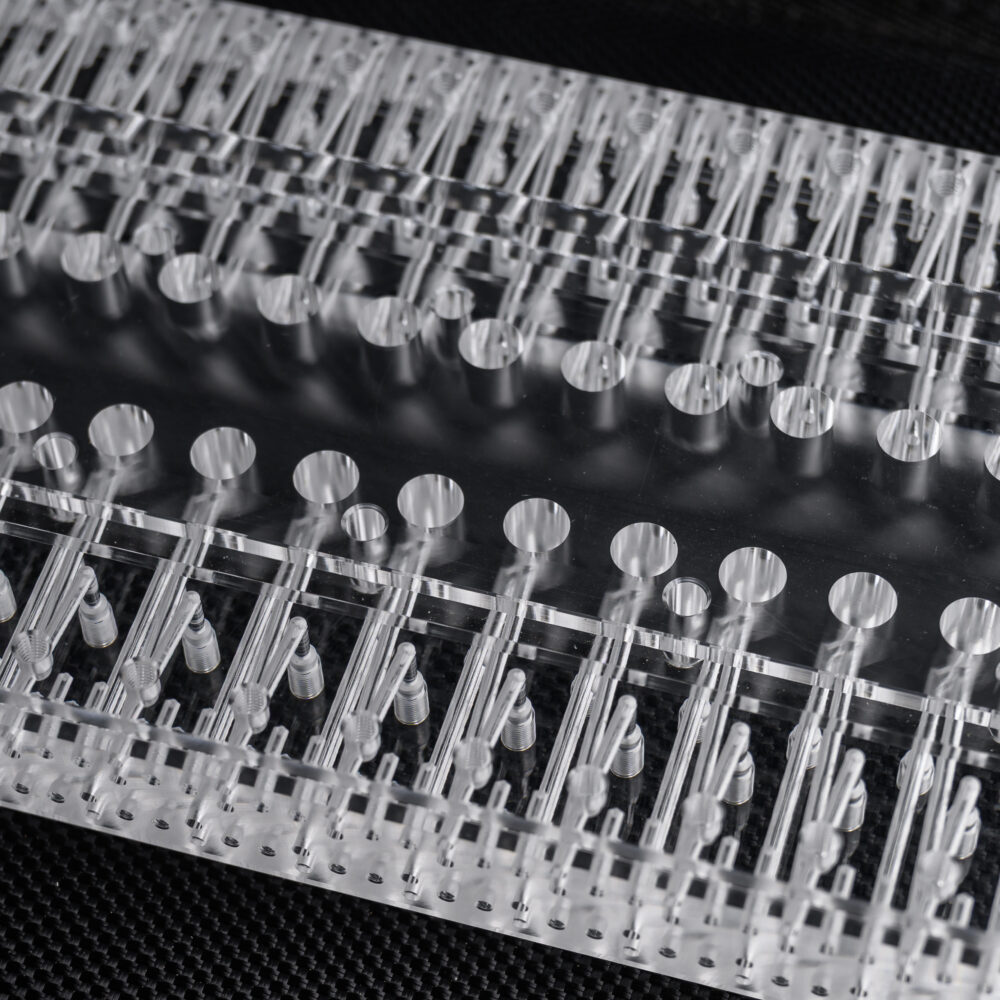

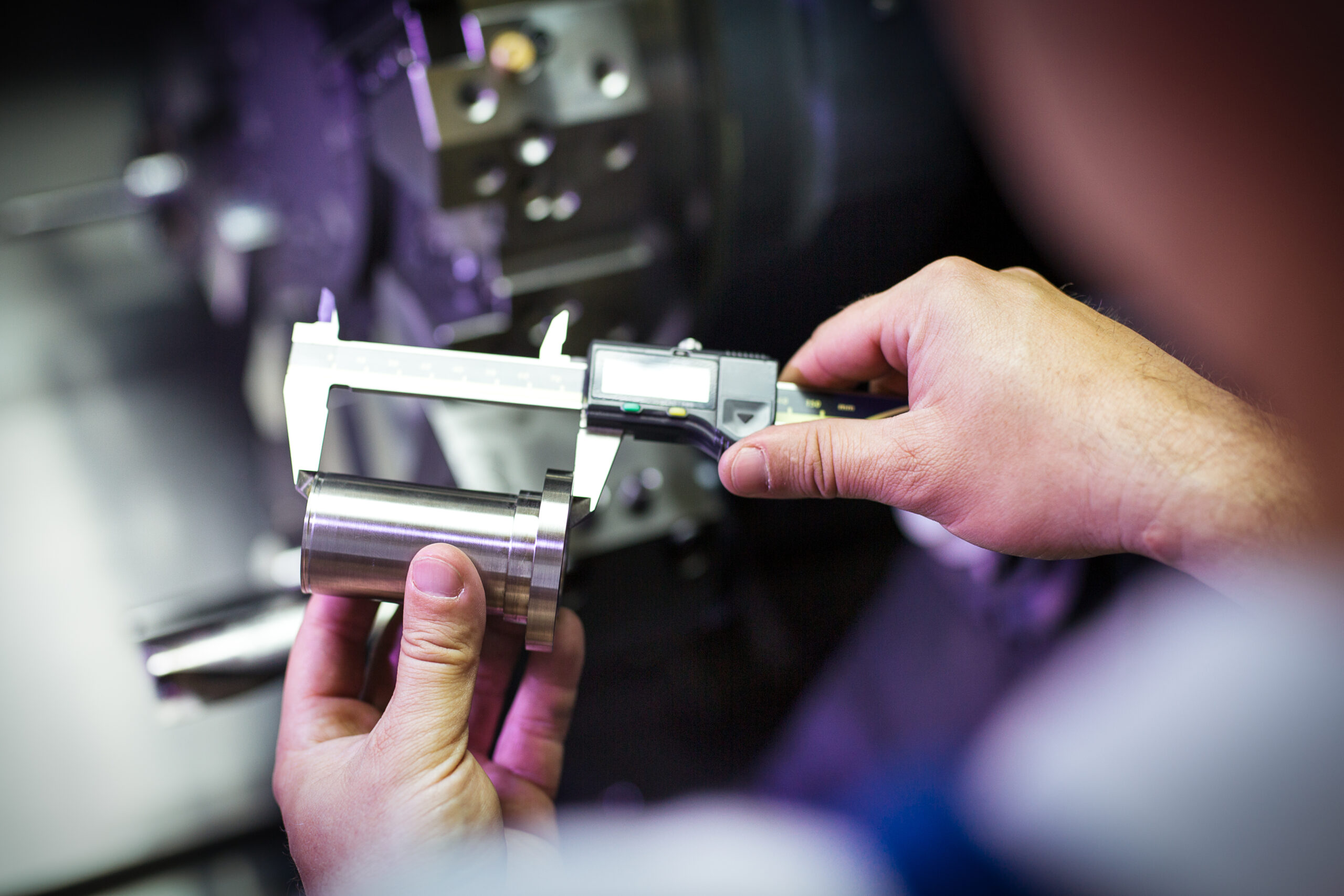

Industrial CT Scanning & Metrology

Non-destructive 3D analysis using Zeiss metrology equipment. Industrial computed tomography (CT) scanning provides complete dimensional validation, internal structure inspection, and quality verification without destructive testing—critical for complex geometries, tight tolerances, and internal features.

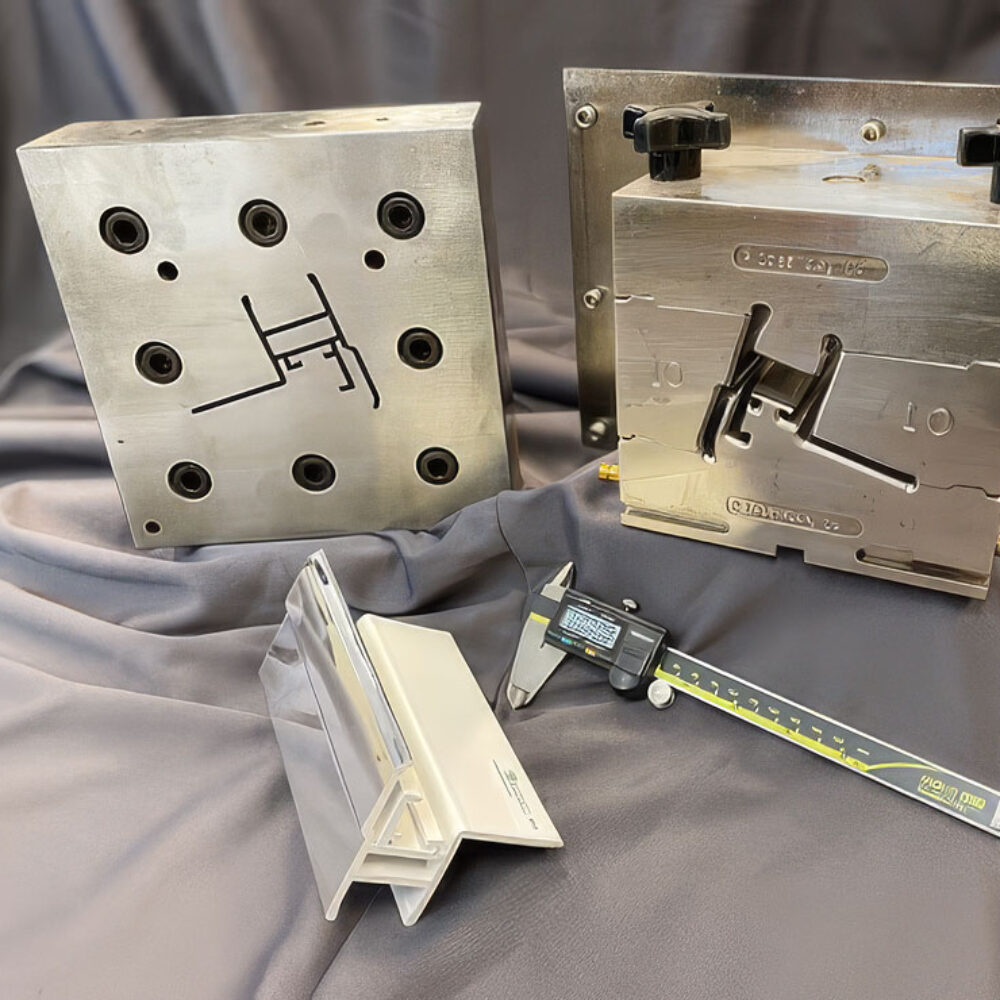

In-House Tooling & Die Manufacturing

Six dedicated tool and die centers across North America eliminate outsourcing delays and maintain direct control over extrusion dies, injection molds, and compression molds. Proprietary tooling designs, rapid modifications, and decades of manufacturing experience translated into optimized tool platforms.

Design Engineering Services

Comprehensive technical support from concept through production. Our engineering teams specialize in material selection, CAD modeling, design for manufacturability (DFM), and process optimization across 500+ plastic resins including ultra-high-performance thermoplastics and fluoropolymers.

Quality Control and Credentials

Pexco maintains comprehensive quality management systems across all manufacturing facilities, with significant investment in state-of-the-art inspection equipment, employee training, and continuous improvement processes.

Certifications & Registration

ISO 9001:2015 Certified

Quality management system certification maintained continuously since 2003, demonstrating consistent capability to meet customer and regulatory requirements.

ITAR Registered

International Traffic in Arms Regulations registration for defense and aerospace applications.

Quality Systems

Comprehensive inspection protocols including incoming material verification, in-process monitoring, statistical process control (SPC), and final inspection. Advanced inspection equipment including CMMs (coordinate measuring machines), optical comparators, vision systems, and automated inspection technologies. Full material traceability and lot tracking for regulated industries.

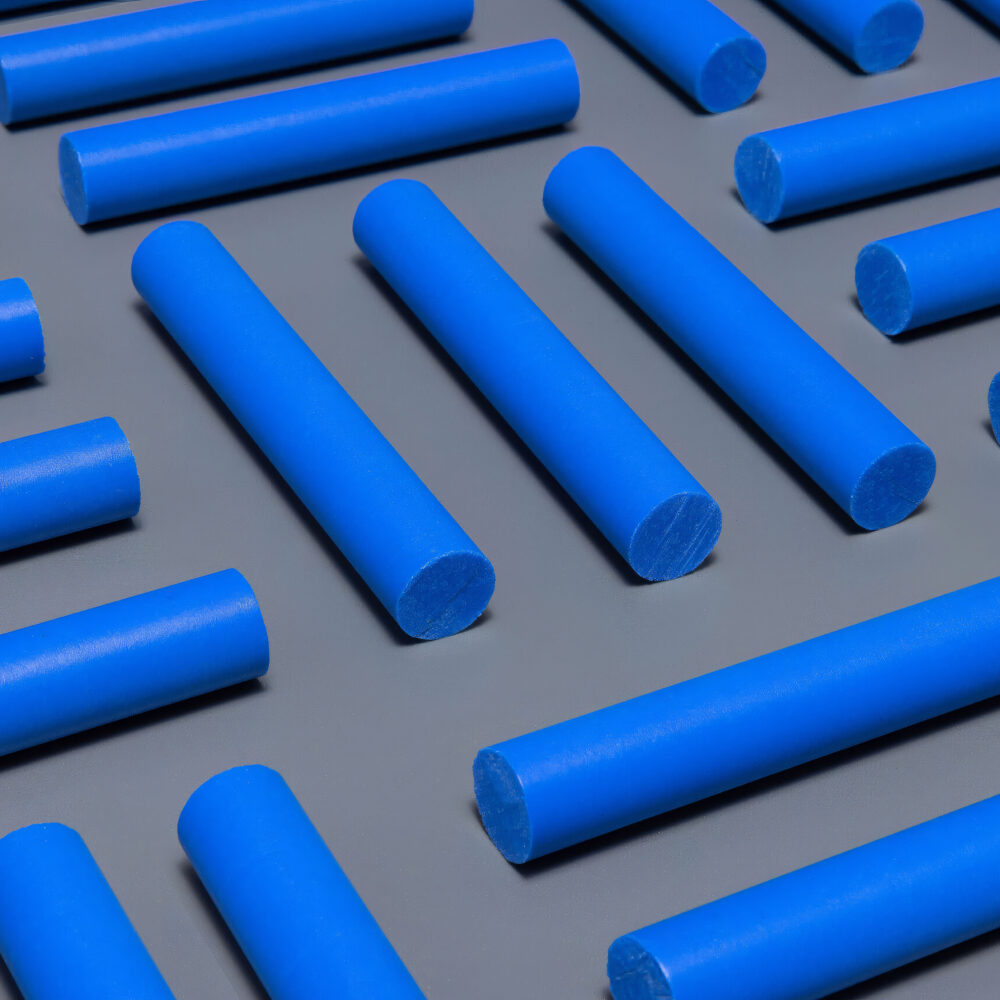

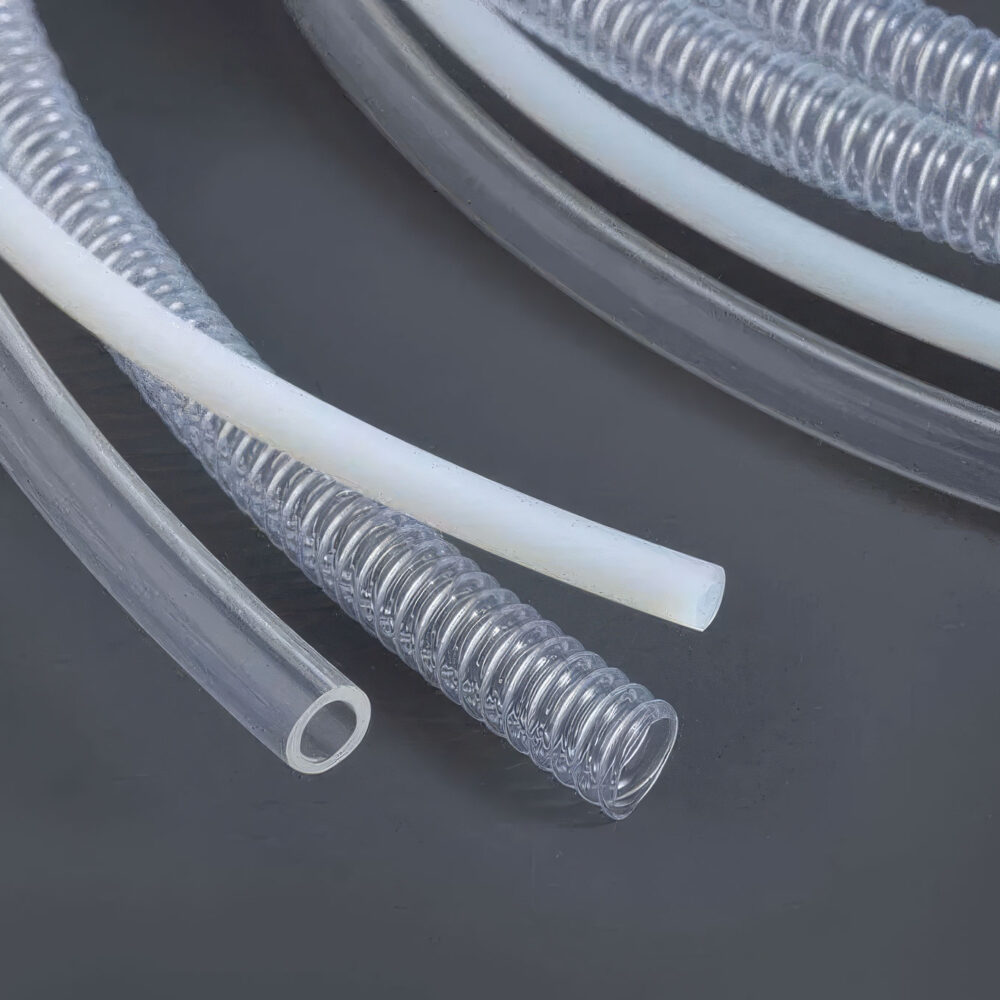

Materials & Resins

Pexco processes over 500 different plastic resins across our Advanced Plastic Engineering capabilities. Material selection, processing parameters, and tooling strategies are optimized for each resin family.

Imidized Polymers

PAI (Polyamide-imide), PBI (Polybenzimidazole)

Advanced Fluoropolymers

PTFE (Flexible & Rigid), PC/TFE, EC/TFE, ETFE, FEP, PFA, HP PFA, UHP PFA, PVDF

Advanced Thermoplastics

PEEK, PSU (Polysulfone), PEI (Ultem), PPS (Polyphenylene Sulfide)

General Plastics (Engineering Grade)

PU (Polyurethane), PA (Nylon), PC/PBT

Commodity Plastics

PVC/FPVC/RPVC, LLDPE, Polycarbonate

Elastomers

EPDM (Sponge & Dense), Silicone (Sponge & Dense), Neoprene, Nitrile, SBR, Polyisoprene, TPE, CIR

Custom & Filled Materials

Glass-filled, carbon-filled, UV-stabilized, flame-retardant, custom color matching, high-temperature compounds

Why Choose Pexco?

6 in-house tool and die centers across North America

Industrial CT scanning with Zeiss metrology equipment

House-built vacuum calibration systems for large-scale profiles

ISO 9001:2015 certified quality systems

ITAR registered for aerospace and defense applications

500+ plastic resins processed with optimized parameters

Tolerances to ±0.001″ on injection-molded components

Tolerances to ±0.005″ on complex hollow extruded profiles

In-house engineering, tooling, and metrology eliminates vendor dependencies

Decades of experience with ultra-high-performance thermoplastics and fluoropolymers

Get Started

Contact Pexco’s engineering team to discuss your technical requirements, material selection, or tooling challenges.