Our Products

Our Brands

Markets

Capabilities

About Pexco

Pexco Capabilities

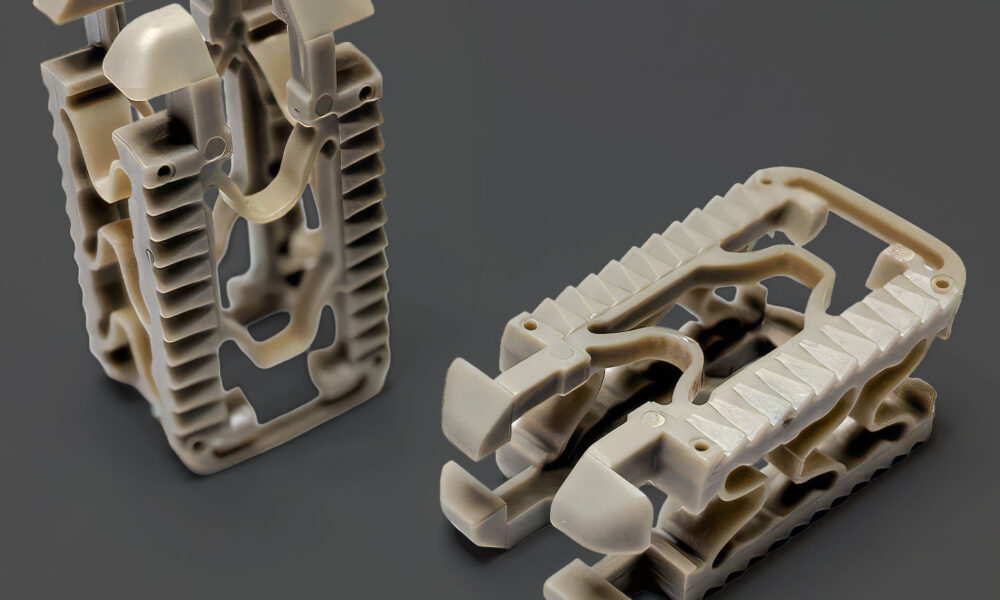

Compression Molding

Where Ideas Take Shape

Pexco’s compression molding capabilities produce high-strength components with uniform properties from thermoset and thermoplastic materials for aerospace, semiconductor, medical, chemical processing, and industrial applications. With over 55 years of compression molding expertise and specialized capabilities for fluoropolymers, high-performance thermoplastics, and thermosets, we deliver components from prototype through production volumes.

Unlike injection molding or extrusion processes that create directional flow and material orientation, compression molding applies uniform pressure to consolidate materials with minimal shear. This produces isotropic mechanical properties—predictable strength, thermal expansion, and chemical resistance in all directions—essential for thick-wall components, filled compounds, and applications requiring dimensional stability under stress.

Isotropy: The Compression Molding Advantage

Compression molding’s pressure-driven consolidation process resists fiber alignment and filler orientation, producing components with balanced stress distribution and uniform performance characteristics. Where injection molding creates anisotropic behavior—directional strength variations from melt flow through gates and runners—compression molding maintains randomized material structure throughout the component.

Why Isotropic Properties Matter:

- Predictable performance under multi-directional loads and thermal cycling

- Reduced warpage and dimensional instability from balanced thermal expansion

- Consistent mechanical properties regardless of stress direction

- Enhanced reliability in demanding environments where directional weakness compromises performance

Compression Molding vs. Other Processes

| Compression Molding | Injection Molding | Extrusion | |

|---|---|---|---|

| Property Distribution | Isotropic—uniform strength and expansion in all directions | Anisotropic—directional strength and shrinkage | Highly anisotropic—strong in flow direction, weaker across |

| Material Flow | Minimal flow; pressure-driven consolidation | High flow through gates and runners | Continuous flow through die |

| Fiber Orientation | Randomized; resists alignment | Directional; fibers align with flow | Strong alignment along extrusion axis |

| Ideal Use Case | Thick, complex parts needing uniform performance | High-volume parts with directional loads | Continuous profiles, tubing, billets |

| Design Implications | Predictable performance in all directions | Requires compensation for directional behavior | Must account for cross-sectional weakness |

Ideal Applications: Semiconductor plasma chamber components, thick-wall chemical processing parts, structural aerospace components, precision seals requiring dimensional stability, and any application where uniform material properties across the component prove critical to performance.

Process Capabilities

Compression molding excels where other processes create limitations. The process accommodates thick cross-sections without sink marks or internal voids, handles highly filled compounds that would challenge injection molding equipment, and produces components with minimal internal stress. Low shear forces during forming preserve fiber length in reinforced materials, maintaining mechanical properties that degrade in high-shear processes.

When to Choose Compression Molding

Thick-wall components (0.187″ to 5″+ thick)

Highly filled materials (glass, carbon, mineral, bronze, graphite)

Parts requiring isotropic mechanical properties

Low- to medium-volume production with custom formulations

Material validation prior to scaling to injection molding or extrusion

Applications where fiber orientation control proves critical

The process proves particularly valuable for prototyping and validating custom formulations before committing to high-volume tooling investments. Compression molds cost less than injection molds, enabling rapid iteration of material blends and part geometries while maintaining production-representative processing conditions.

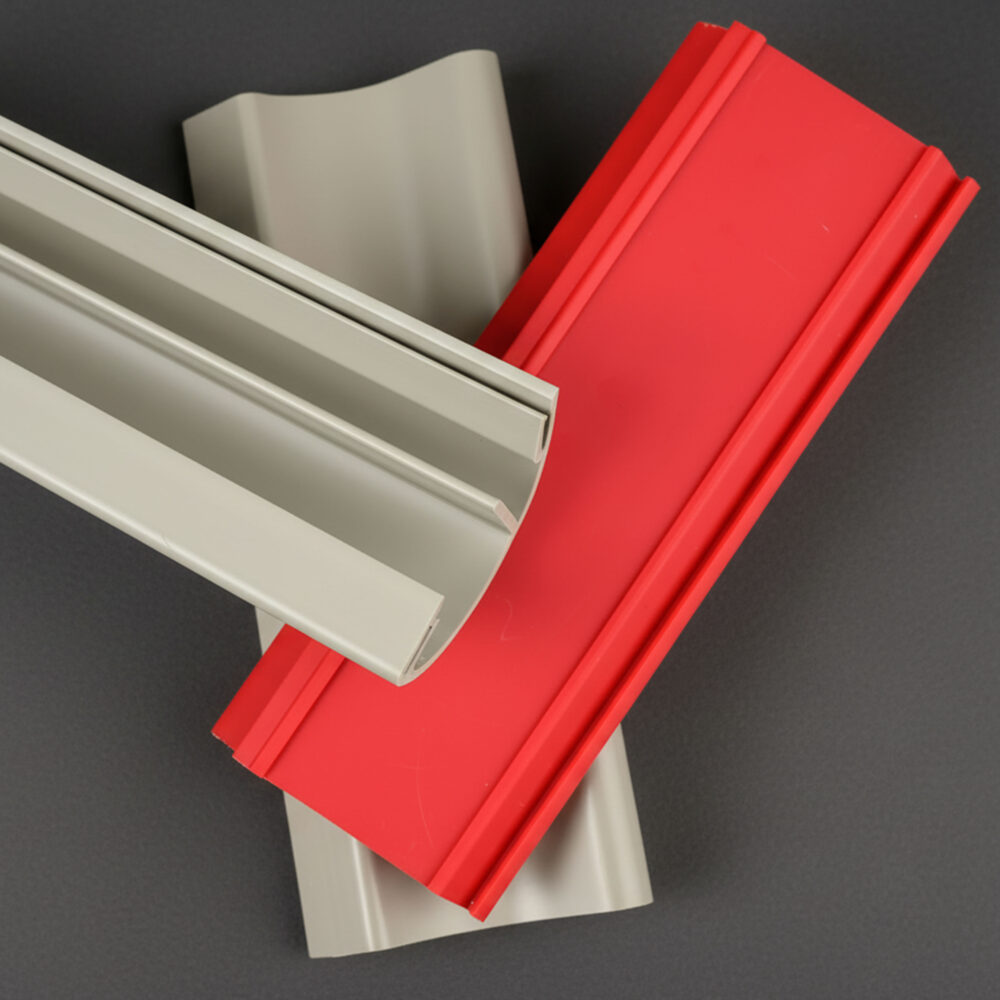

PTFE & Fluoropolymer Compression Molding

Pexco compression molds virgin and filled PTFE in configurations ranging from thin sheets to thick billets, serving applications requiring chemical resistance, low friction, high-temperature tolerance, and dimensional stability. Our Enflon® brand encompasses standard and filled PTFE compounds optimized for specific performance requirements.

Compression Molded PTFE Capabilities

| Product Type | Size Range | Tolerances | Additional Options |

|---|---|---|---|

| Molded Sheets | Thickness: 0.187″ to 5″ (3″+ untrimmed) Standard sizes: 24″ x 24″ up to 48″ x 48″ | +0.060″ (thin) to +16% (thick) | Etched one-side, two-side, or adhesive backing |

| Molded Rods | Diameter: 1.25″ to 20.5″ OD Standard length: 12″ | +0.25″ (small) to +6% (large) | Custom lengths available |

| Molded Cylinders | OD: 1.125″ to 34.5″ ID: 0.500″ to 30.125″ Standard length: 12″ | OD: +0.25″ to +6% ID: -0.25″ to -6% | Custom ID/OD combinations |

Enflon® Filled PTFE Compounds

- Glass-filled: 40% improvement in compressive strength, enhanced wear resistance

- Carbon-filled: Superior wear characteristics, improved thermal conductivity

- Bronze-filled: High mechanical loads, heat dissipation in high-speed applications

- Graphite-filled: Improved chemical resistance, excellent dry lubricity

- Blended fillers: Custom combinations for specific performance requirements

These compression molded forms serve as machining stock for precision components, skiving feedstock for thin films and tapes, and finished parts for seals, gaskets, bearing surfaces, and chemical processing equipment.

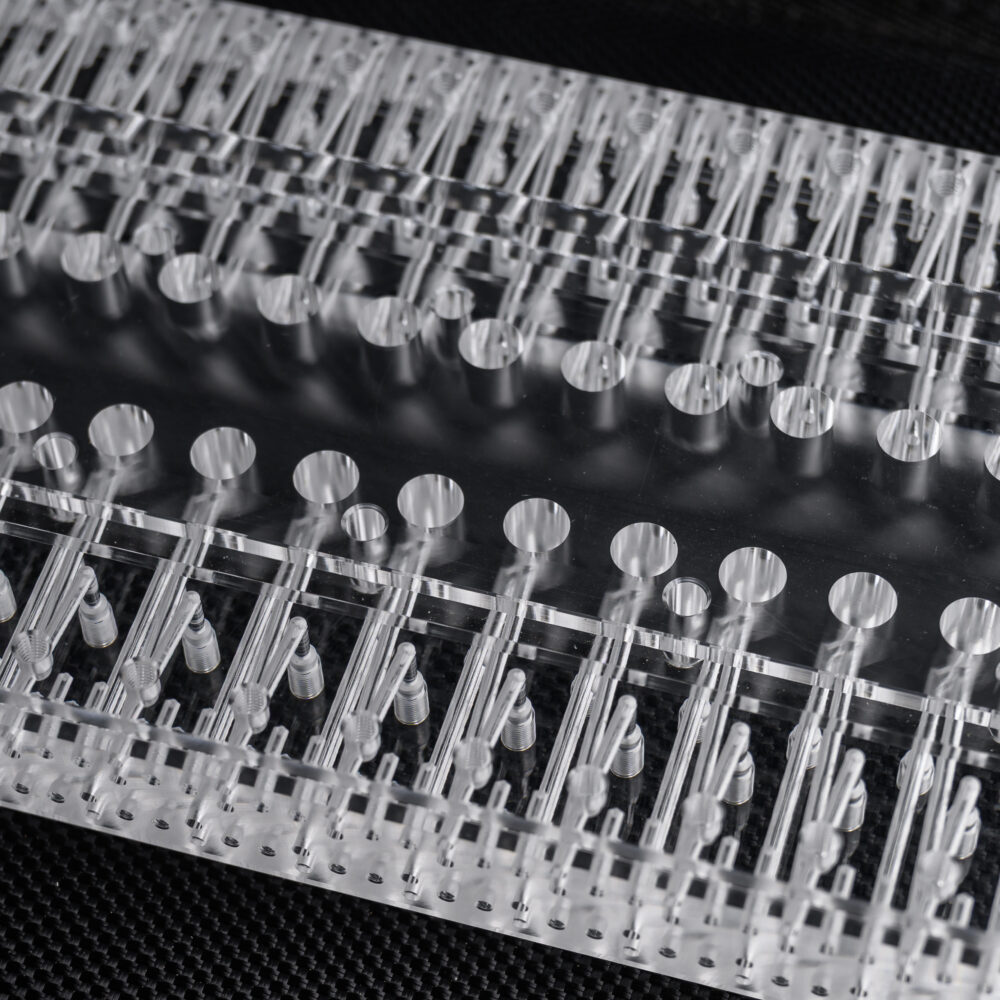

High-Performance Thermoplastic Compression Molding

Pexco compression molds advanced thermoplastics requiring tight tolerances and demanding material properties. These materials prove challenging in injection molding due to high processing temperatures, aggressive chemical resistance, or application requirements favoring isotropic properties.

Compression molding PEEK, Torlon (PAI), Ultem (PEI), and Ryton (PPS) produces components for aerospace structures, semiconductor process equipment, medical device housings, and industrial applications requiring predictable performance under thermal and mechanical stress. The isotropic properties achieved through compression molding prove particularly valuable for structural components where directional weakness would compromise performance.

Thermoset Compression Molding

Thermoset compression molding produces components with superior heat resistance, dimensional stability, and mechanical strength through irreversible chemical crosslinking during the molding process. Once cured, thermosets maintain dimensional stability and mechanical properties at elevated temperatures where thermoplastics soften or deform.

Typical Applications

- Electrical insulators and housings requiring high dielectric strength

- Automotive under-hood components exposed to continuous heat

- Industrial equipment components requiring dimensional stability under load

- Chemical processing equipment for corrosive environments

Secondary Operations & Finishing

Compression molded components integrate with our complete manufacturing capabilities:

Stress Relief (Annealing): Controlled thermal processing removes residual stresses, optimizing dimensional stability and long-term performance. Particularly important for thick-wall components and parts machined from compression molded stock.

Precision Machining: Compression molded billets, cylinders, and sheets serve as feedstock for CNC milling, turning, and Swiss machining operations, producing finished components with complex geometries from our [Precision Machining] capabilities.

Surface Finishing: Etching for bonding applications, dimpling for enhanced lubrication in bearing applications, and cutting to custom sizes complement our compression molding services.

Materials & Resins

Pexco compression molds high-performance materials requiring dimensional stability and uniform properties:

Fluoropolymers

Virgin PTFE, Modified PTFE, Enflon® filled PTFE compounds – For chemical resistance, low friction, and high-temperature applications

Imidized Polymers

PAI (Torlon), PBI – For extreme temperature and wear resistance

Advanced Thermoplastics

PEEK, PEI (Ultem), PPS (Ryton) – For structural components requiring high strength and thermal stability

Thermosets

For heat resistance and dimensional stability under continuous elevated temperature

Filled Compounds

Glass, carbon, graphite, bronze, mineral fillers – For enhanced mechanical properties, wear resistance, and thermal management

Why Choose Pexco?

55+ years compression molding experience

Isotropic properties for predictable multi-directional performance

PTFE compression molding from 0.187″ to 5″ thick, up to 48″ x 48″

Cylinders to 34.5″ OD for large-bore applications

High-performance thermoplastics: PEEK, Torlon, Ultem, Ryton

Thermoset capabilities for heat-resistant components

Enflon® filled PTFE compounds with custom formulations

Low- to medium-volume production flexibility

Rapid prototyping and material validation

ISO 9001:2015, AS9100, ITAR certified

Integrated precision machining and finishing services

Complete design engineering support

Get Started

Contact Pexco’s compression molding team to discuss your component requirements and material specifications.