Our Products

Our Brands

Markets

Capabilities

About Pexco

Pexco Capabilities

Custom Profile Extrusions

Where Ideas Take Shape

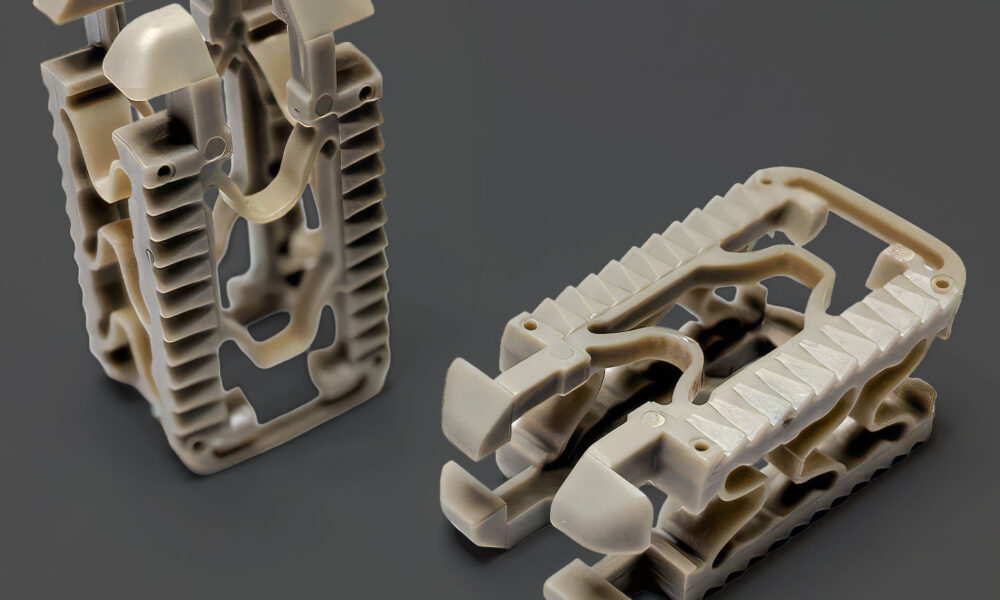

Pexco is a leading provider of custom plastic profile extrusion with over 150 extrusion lines across North America. We specialize in complex multi-layer extrusions, large-scale profiles, and precision hollow structures—from simple solid forms like custom rods and bars to highly complex geometries with integrated features like channels, clips, and hinges.

Our capabilities range from 1/8″ miniature profiles to 30″+ wide large-scale extrusions. With six in-house tool and die centers and expertise processing over 50 different plastic resins, we deliver engineered solutions from prototype to high-volume production.

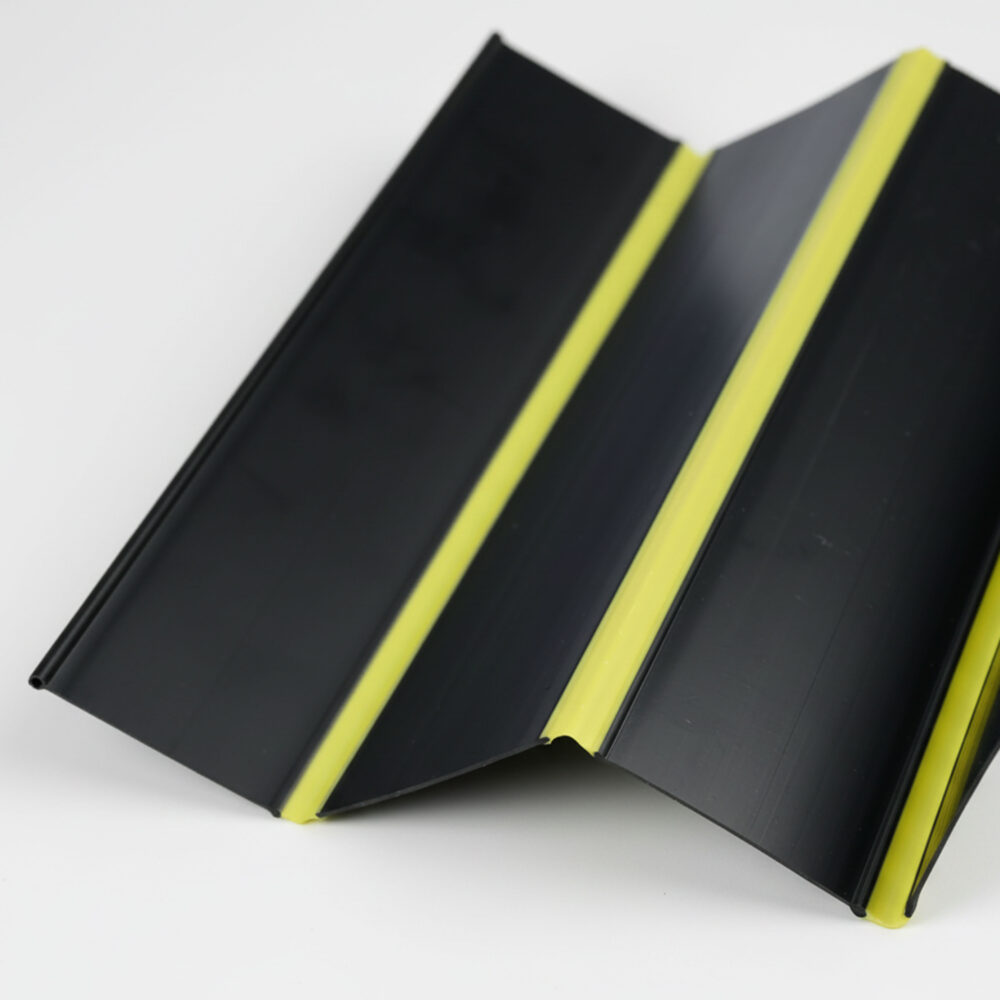

Co-Extrusion and Tri-Extrusion

Co-extrusion simultaneously combines two or more different materials through a single die to create a composite profile with multiple distinct layers. Tri-extrusion expands this capability to three materials in one profile.

The process uses heat and pressure within the extrusion die to bond dissimilar plastics, enabling combinations of different durometers, colors, and plastic types in a single part. Ideal applications include lighting components with transparent and opaque sections, flexible hinges fused to rigid structures, and gaskets requiring multiple material properties.

Crosshead Extrusion

Crosshead extrusion coats and envelops materials like wire, cable, or metal shapes with plastic by feeding them through a “crosshead” at the extrusion die. This technique allows solid substrates—such as copper wire or fibrous materials—to integrate into the plastic melt, creating a durable composite product.

- Single-layer crosshead extrusion for uniform coating

- Co-extrusion and multi-layer crosshead solutions for complex performance requirements

- Commonly used in wire and cable manufacturing

- Ideal for custom applications where substrates cannot pass through the extruder’s screw and barrel

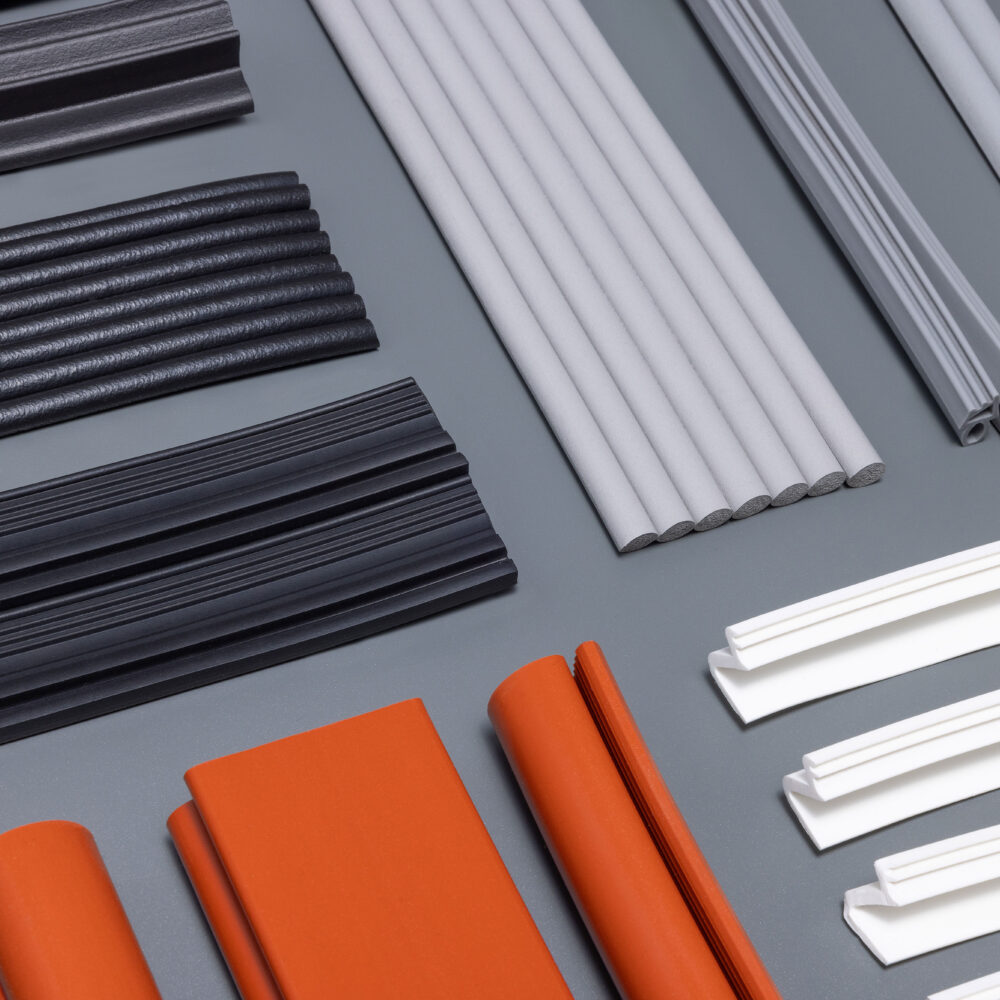

Elastomer Extrusion

Pexco specializes in both dense and sponge elastomer extrusions, providing flexibility, resilience, and durability for demanding applications. We manufacture extruded rubber and elastomer profiles in all shapes, sizes, and lengths using over 3,000 custom dies engineered to meet diverse application requirements.

- Dense elastomers for seals, gaskets, and weatherstripping

- Sponge elastomers for cushioning, insulation, and vibration dampening

- Over 11 dedicated elastomer extruders spanning 110,000+ square feet

- In-house tool and die shop for custom profile development

- Secondary operations including splicing, vulcanizing, and fabrication

Meta-Plast™ Technology

Meta-Plast is a proprietary co-extrusion process that permanently bonds plastic materials to metal substrates during extrusion. Products produced with Meta-Plast exhibit low coefficient of linear thermal expansion (CLTE) and higher flex modulus compared to conventional extrusions, delivering enhanced dimensional stability and structural integrity for demanding applications.

Celuka Foam Extrusion

Celuka is an inward foaming process that creates lightweight profiles with a solid outer skin and cellular foam core. The process suppresses cell formation at the surface, creating a hard, high-quality finish while allowing the interior to expand into a cellular structure.

Celuka foam benefits:

- Reduced material density while maintaining strength

- Excellent thermal insulation properties

- Fastener retention comparable to wood

- Multiple post-finishing options (painting, laminating, machining)

- Cost-effective material reduction without sacrificing performance

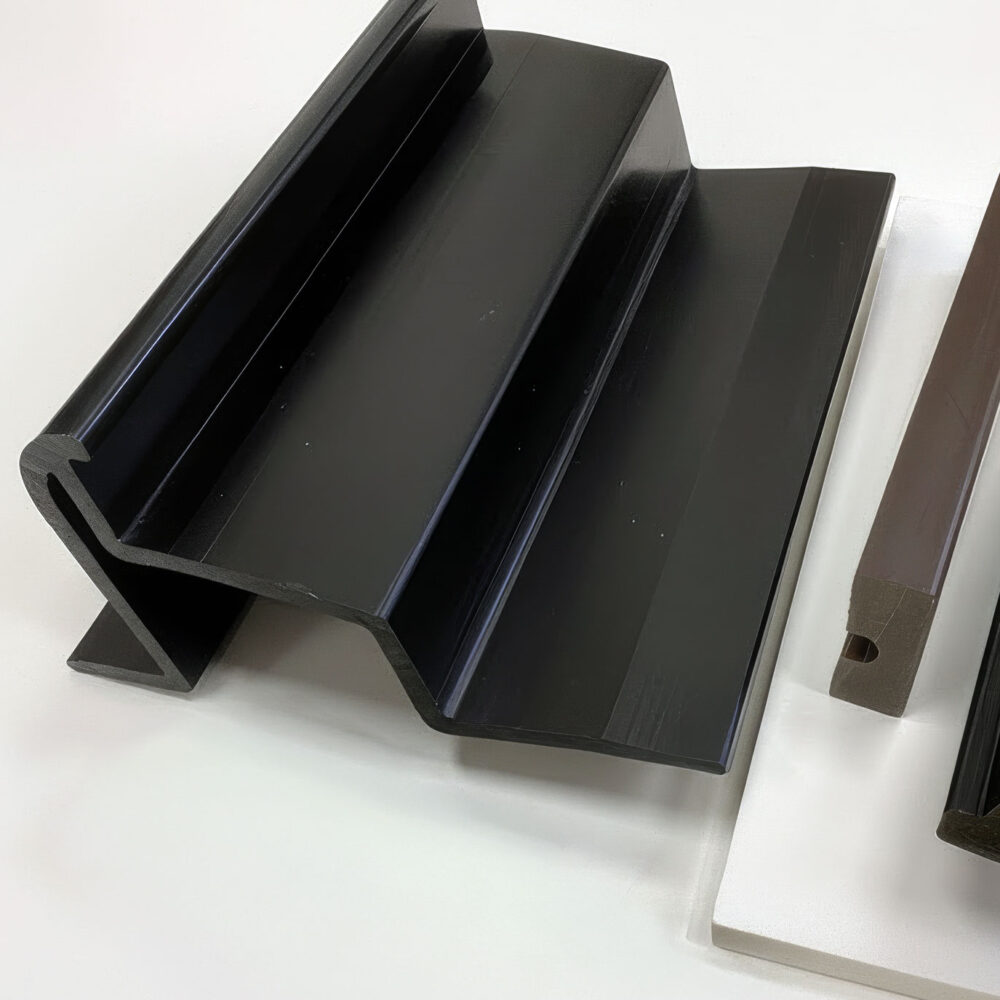

Large-Scale Profile Extrusions

Pexco manufactures some of the largest custom plastic profile extrusions in North America using advanced Vacuum Calibration Technology. Our profiles can exceed 30 inches in width and 6 inches in height, with house-built custom vacuum sizing equipment ensuring dimensional consistency at scale.

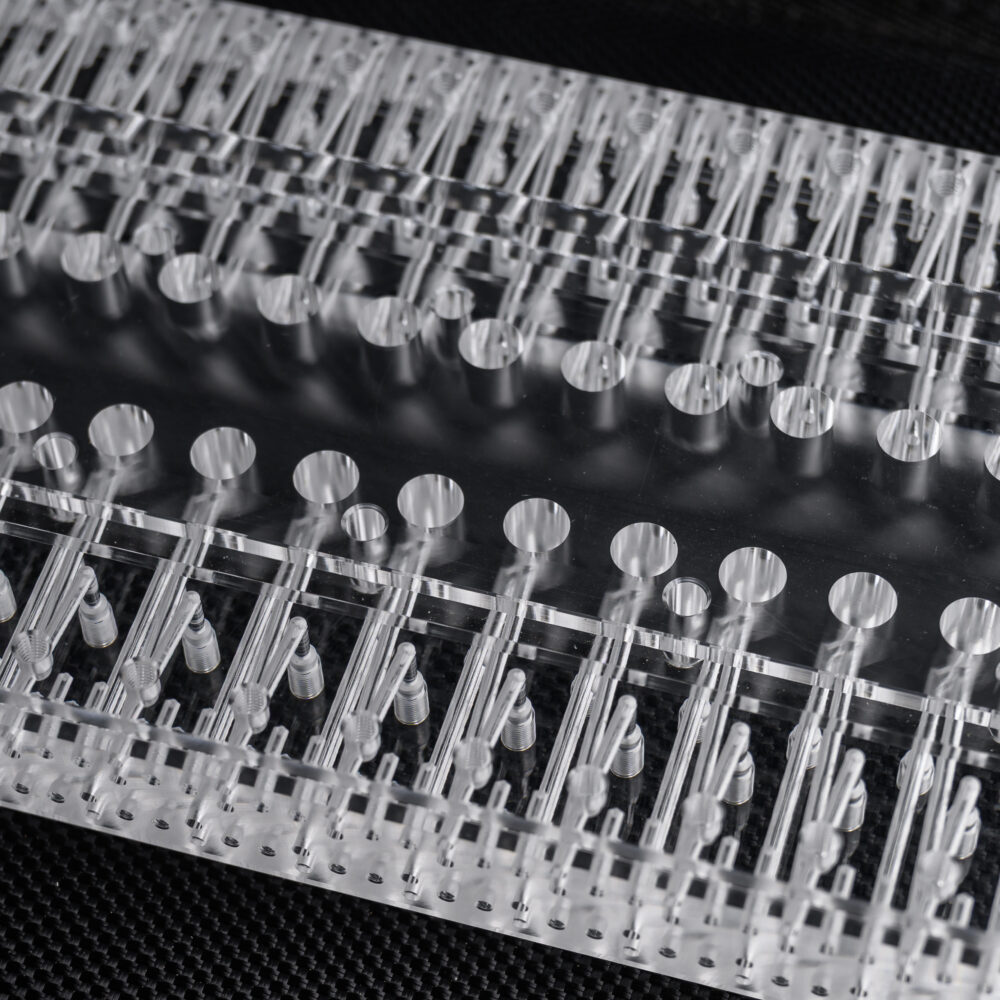

Hollow Profile Extrusion

We specialize in complex hollow profile extrusions with multiple internal chambers and dimensional tolerances as tight as ±0.005 inches. Our proprietary tooling platforms and vacuum calibration technology deliver precise internal geometries for lightweight, structurally efficient designs with integrated channels for wiring, fluid routing, or enhanced insulation.

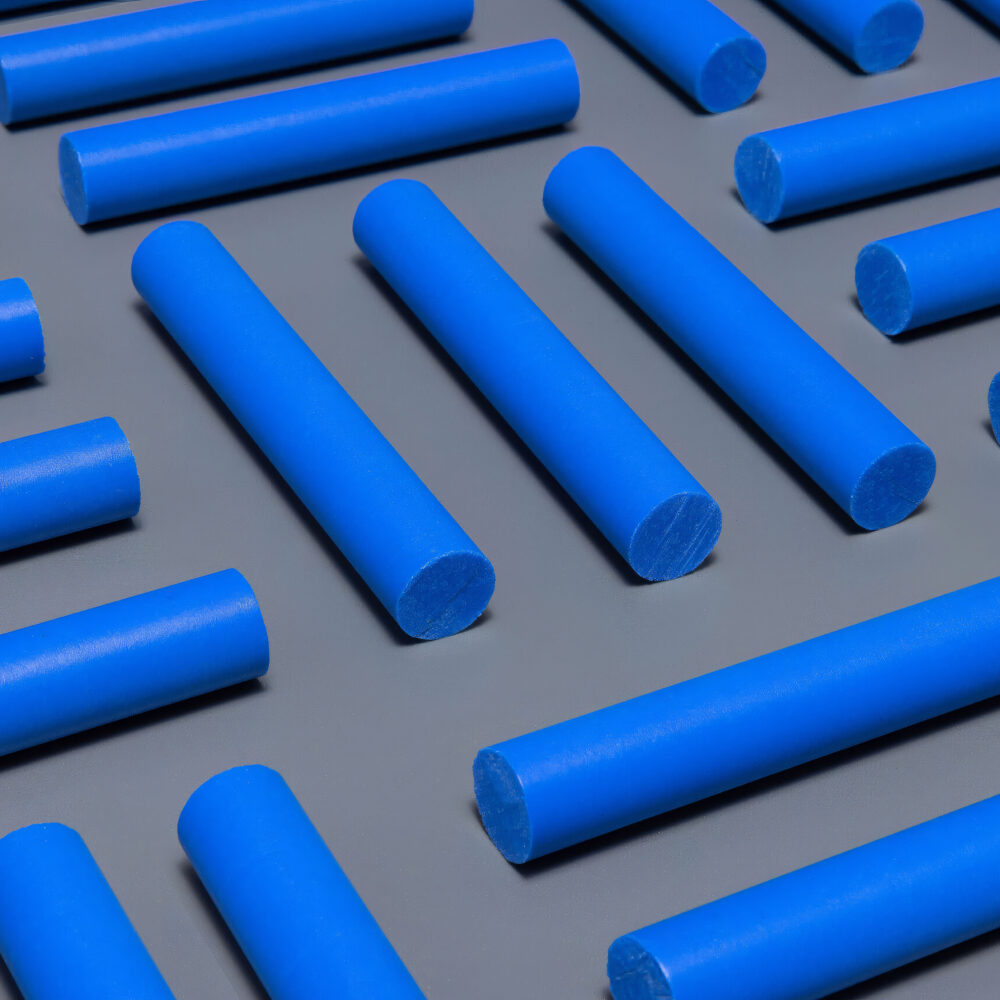

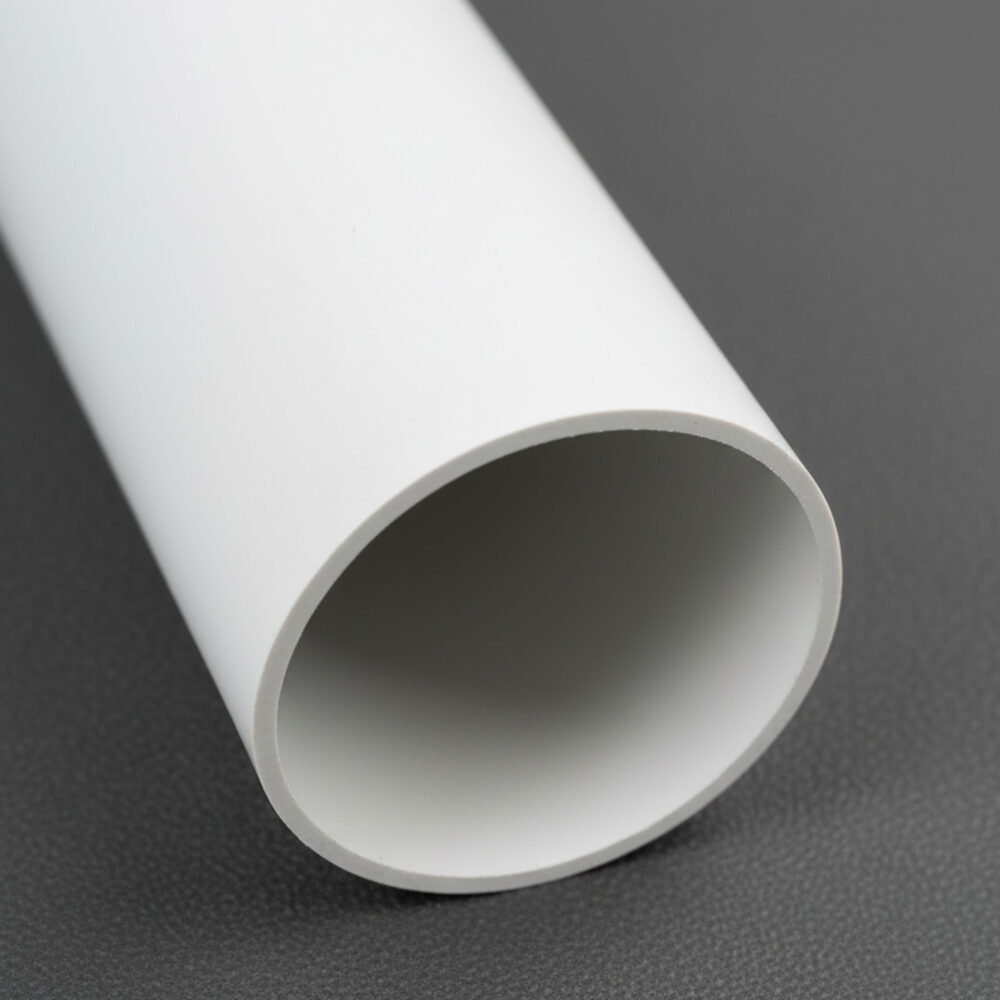

Plastic Core Tubes

Pexco has produced hundreds of thousands of plastic core tubes over the past 40 years, serving manufacturers in the film, tape, and textile industries. Our core tubes offer a dependable, economical solution for applications requiring strong, clean, moisture-resistant tubing for winding operations.

- Extruded primarily from High Impact Polystyrene (HIPS) or Polyethylene (HDPE)

- Custom diameters, wall thicknesses, and lengths available

- Secondary operations including notching, punching, and two-sided adhesive starter tape

- Manufactured from almost any thermoplastic material to meet specific requirements

Surface Finishes

Pexco offers multiple in-line and post-extrusion surface finishing options to achieve specific aesthetic and functional requirements.

Hot Stamping

In-line hot stamping applies decorative laminates during extrusion using heat and pressure. Achieve wood grain finishes (oak, walnut, mahogany) or brushed metal appearances (stainless, aluminum) with hundreds of stock patterns available or custom finishes for specific requirements.

Embossing

In-line embossing creates permanent, dimensional surface textures by pressing patterns into molten plastic. Custom textures available for leather, fabric, geometric designs, and enhanced grip properties.

Spattercoat

Our proprietary Spattercoat process creates distinctive multi-toned texture finishes for high-end aesthetic applications.

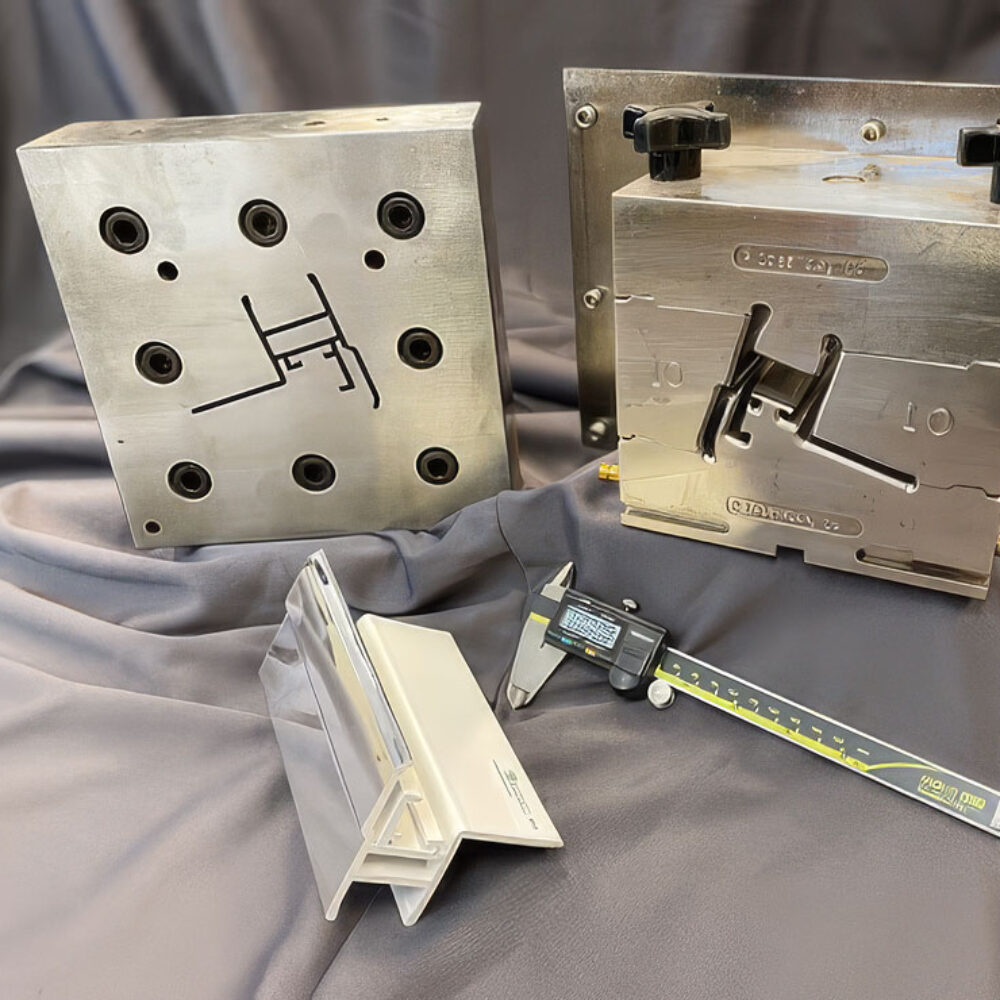

Custom Extrusion Design Services

Pexco’s engineering team provides comprehensive design support:

- Material selection and optimization

- Cross-sectional design and CAD modeling

- Prototype development and testing

- Design for manufacturability (DFM) analysis

- Tool and die design in-house

- Production process optimization

See Design Engineering Services for complete engineering capabilities.

Materials & Resins

Pexco processes over 500 different plastic resins for custom profile extrusion:

Imidized Polymers

PAI (Polyamide-imide), PBI (Polybenzimidazole)

Advanced Fluoropolymers

PTFE (Flexible & Rigid), PC/TFE, EC/TFE, ETFE, FEP, PFA, HP PFA, UHP PFA, PVDF

Advanced Thermoplastics

PEEK, PSU (Polysulfone), PEI (Ultem)

General Plastics (Engineering Grade)

ABS, PU (Polyurethane), PA (Nylon), PC/PBT

Commodity Plastics

PVC/FPVC/RPVC, LLDPE, HDPE, Polycarbonate, Polystyrene (HIPS), Polypropylene

Elastomers

EPDM (Sponge & Dense), Silicone (Sponge & Dense), Neoprene, Nitrile, SBR, Polyisoprene, TPE, CIR

Custom & Filled Materials

Glass-filled, carbon-filled, UV-stabilized, flame-retardant, custom color matching

Why Choose Pexco?

150+ extrusion lines across North America

6 in-house tool and die centers

3,000+ custom dies for elastomer profiles

500+ plastic resins processed

Proprietary technologies: Meta-Plast, Celuka, Spattercoat

Size range: 1/8″ to 30″+ profiles

Precision: ±0.005″ tolerances

40+ years experience in specialty tubing and core tubes

Stock Shapes & Specialty Products

Looking for stock shapes or specialty products? Pexco also manufactures sheet, film, rod, tubing, and heat shrink products in a variety of high-performance materials.

Get Started

Contact Pexco’s extrusion engineering team to discuss your custom plastic profile requirements.