Our Products

Our Brands

Markets

Capabilities

About Pexco

Pexco Capabilities

Precision Machining

Where Ideas Take Shape

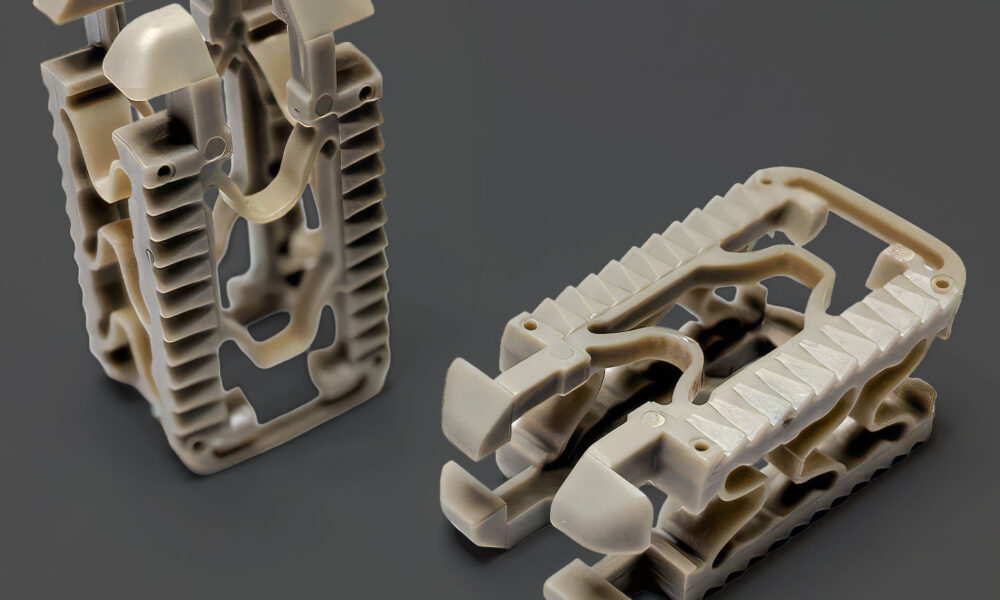

Pexco’s precision machining capabilities transform high-performance plastic materials into complex components with tight tolerances for aerospace, medical, semiconductor, and industrial applications. With over 40 CNC machines including 3-, 4-, and 5-axis mills, multi-axis mill-turns, and Swiss turning equipment, we machine components from micro-scale parts to 20-inch diameter turned components. Our temperature-controlled facilities and expertise in machining challenging materials like PEEK, Torlon, PFA, and filled compounds enable us to achieve exceptional surface finishes and dimensional accuracy.

From prototype to production, our machining services complement our molding and extrusion capabilities to deliver complete manufacturing solutions including secondary operations, stress relieving, and advanced surface finishing techniques like vapor polishing for optical-clarity applications.

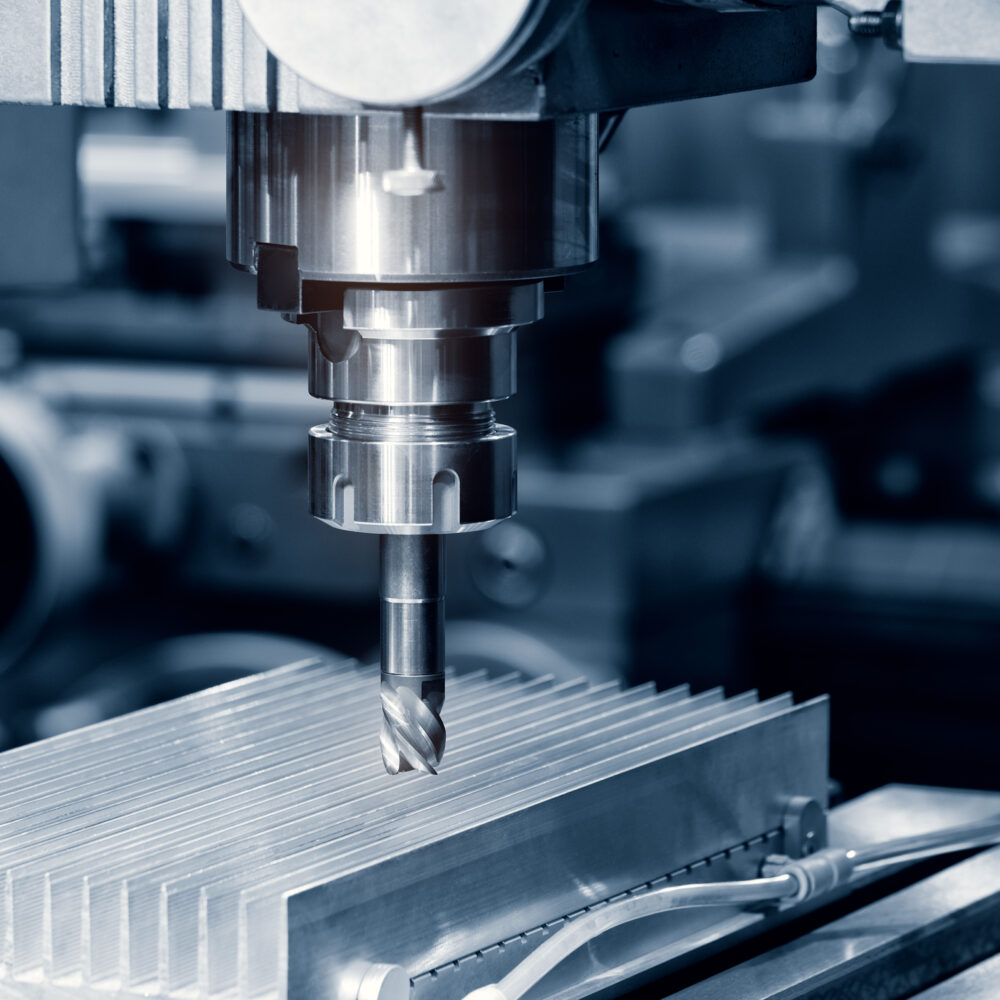

CNC Milling

We operate 3-, 4-, and 5-axis CNC milling equipment capable of producing complex geometries with tight tolerances from solid stock, castings, or molded components. Three-axis milling handles straightforward prismatic parts efficiently, while 4-axis capabilities add rotary indexing for features around cylindrical components. Five-axis simultaneous machining enables complex contoured surfaces and compound angles in a single setup, eliminating multiple repositioning operations.

Our temperature-controlled machining environment proves critical when working with thermoplastics that expand and contract with thermal variation. Vision coordinate measuring machines (CMM) and toolmaker microscopes provide precision measurement throughout the process, while advanced CAD/CAM software integration allows direct import of customer files for seamless programming and rapid prototype-to-production transitions.

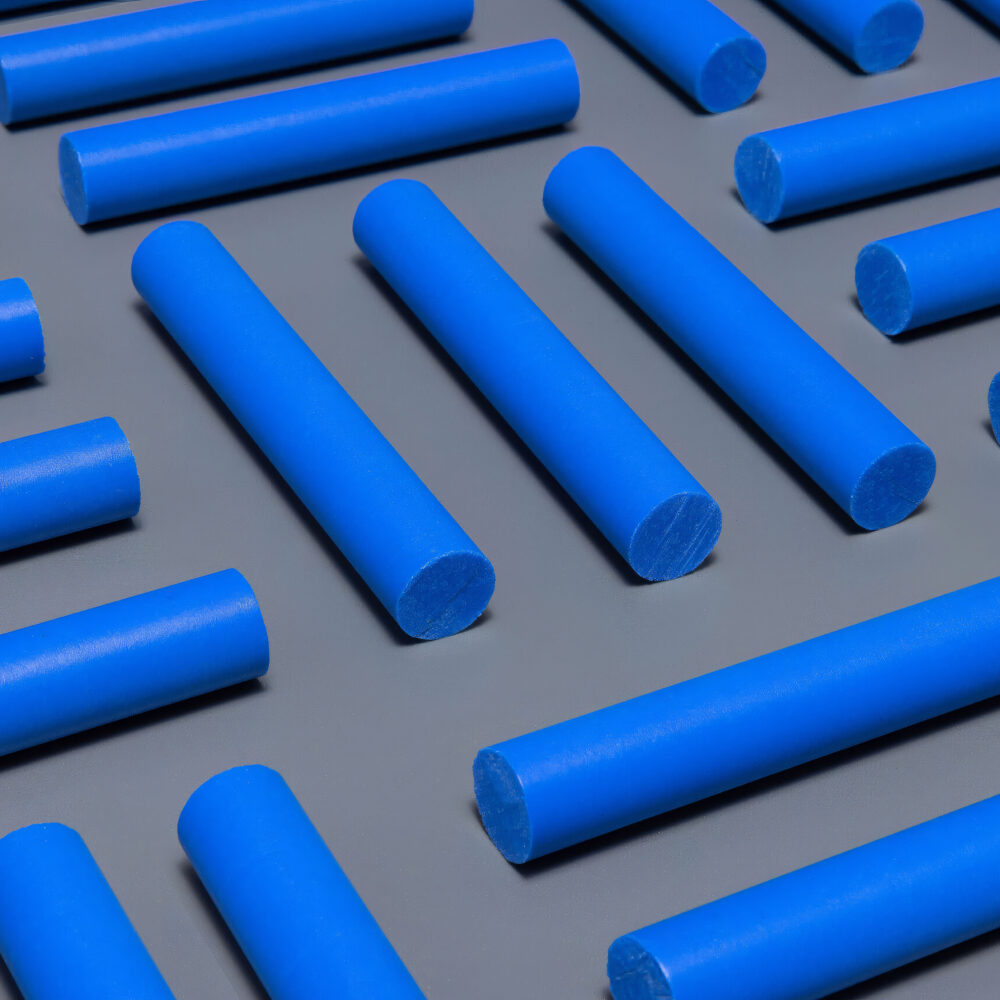

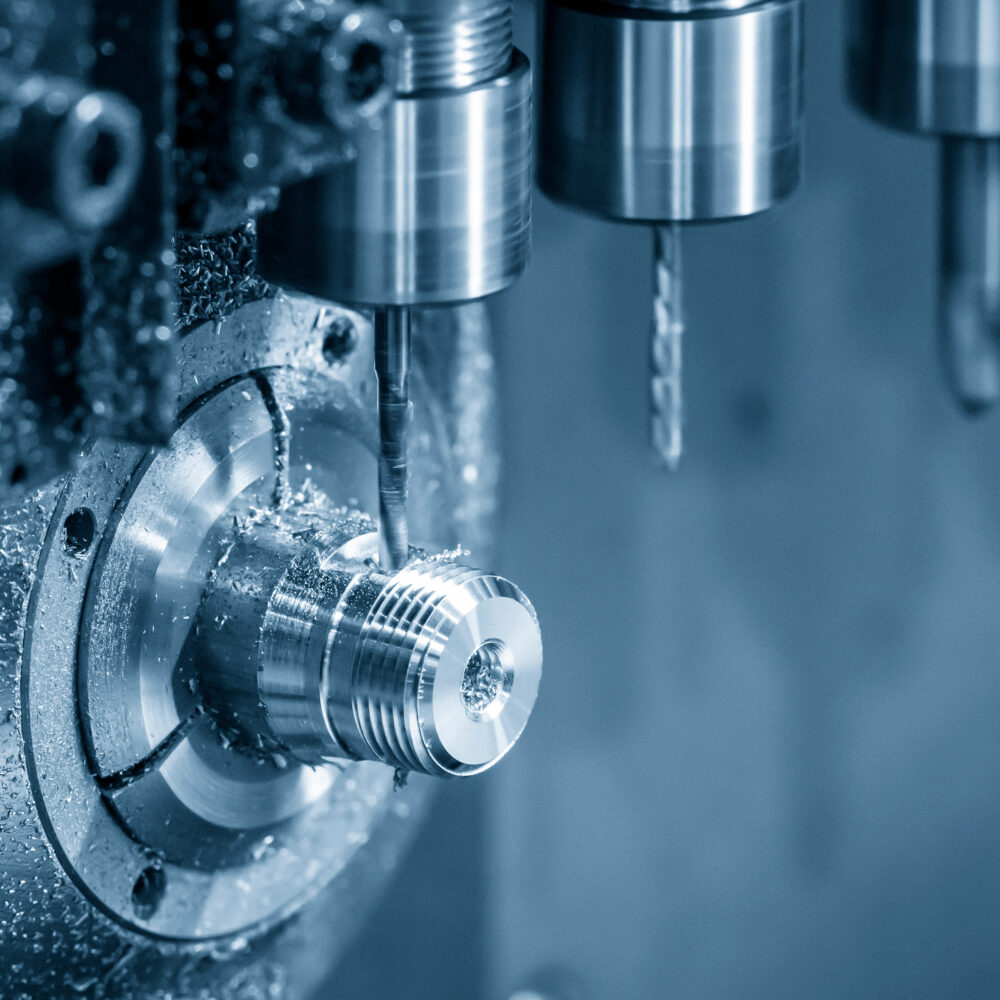

CNC Turning & Swiss Machining

Our CNC turning capabilities range from micro-machining of miniature components to large-diameter parts up to 20 inches, utilizing multi-axis mill-turn equipment with sub-spindles and live tooling. With over 40 CNC turning and Swiss machining centers, we efficiently handle both prototype quantities and production volumes.

Key Capabilities

- Complete part production in a single setup incorporating turned features, cross-holes, slots, and complex geometries

- Multi-axis mill-turns with live tooling eliminate secondary operations

- Sub-spindles enable front and back machining without repositioning

Swiss Machining: Swiss-type CNC machines excel at producing small-diameter precision components with exceptional accuracy and surface finish. The Swiss turning process supports the workpiece very close to the cutting tool, minimizing deflection and enabling tight tolerances on slender parts that would be impractical with conventional turning. Particularly valuable for medical device components, connectors, and instrumentation parts requiring multiple features machined to close tolerances in a single operation.

Surface Finishing & Treatment

High-performance plastic components often require specialized surface finishing and heat treatment processes to achieve optimal performance:

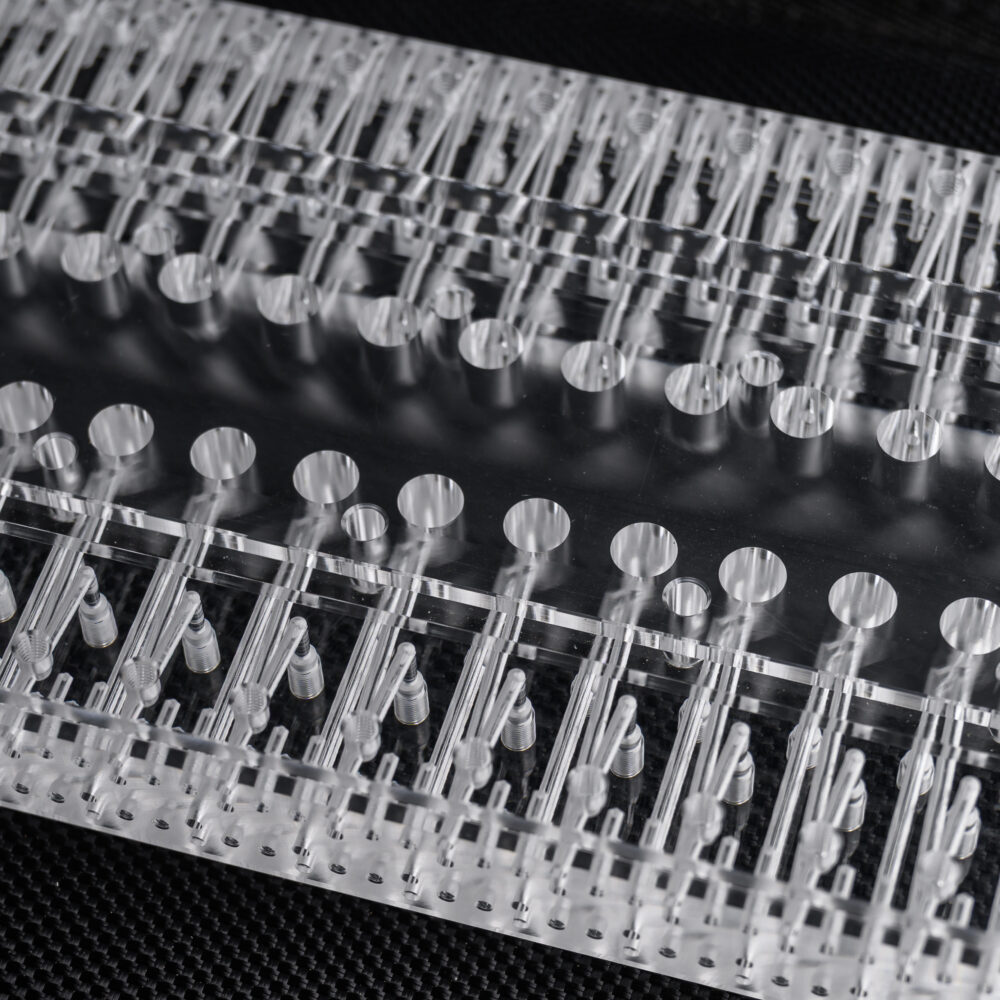

Vapor Polishing

Creates optically clear, defect-free surfaces on transparent and translucent plastics by briefly exposing machined parts to solvent vapor that smooths surface irregularities at the molecular level. Eliminates machining marks and achieves glass-like clarity without dimensional changes, ideal for optical components, medical devices, and high-visibility applications.

Annealing and Stress Relieving

Remove internal stresses introduced during machining, preventing dimensional instability, cracking, or warpage in service. Our controlled thermal processing optimizes material properties and dimensional stability, particularly important for precision components operating in demanding thermal environments or requiring long-term dimensional consistency.

Additional Finishing Options

Flame polishing, mechanical buffing, and surface texturing to meet specific functional or aesthetic requirements.

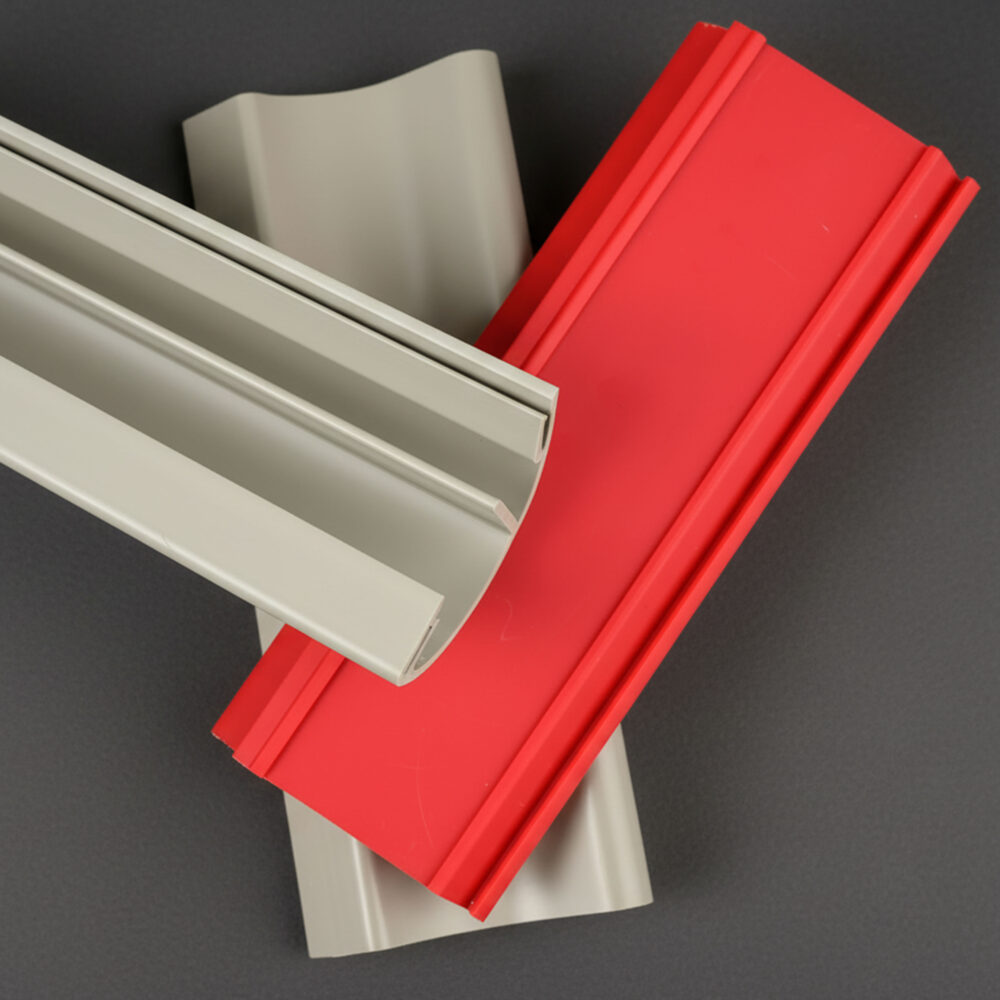

Materials & Resins

Pexco machines a comprehensive range of high-performance plastics:

Imidized Polymers

PAI (Torlon), Vespel (Polyimide), PBI – For extreme temperature and wear resistance

Advanced Fluoropolymers

PTFE, FEP, PFA, PVDF, ETFE – For chemical resistance and low-friction applications

Advanced Thermoplastics

PEEK, PEI (Ultem), PSU (Polysulfone), PPS (Ryton), EXTEM – For structural components requiring high strength and thermal stability

Filled Materials

Glass-filled, carbon-filled, mineral-filled compounds – For enhanced dimensional stability and mechanical properties

Commodity Engineering Plastics

Nylon, Acetal, Polycarbonate, Acrylic – For cost-effective precision components

Why Choose Pexco?

40+ CNC milling, turning, and Swiss machining centers

3-, 4-, and 5-axis milling for complex geometries

Multi-axis mill-turns with live tooling and sub-spindles

Swiss machining for micro to precision-diameter components

Turning capacity from micro-scale to 20-inch diameter

Temperature-controlled machining environments

Vision CMM and toolmaker microscope measurement systems

Vapor polishing for optical-clarity surface finishes

Annealing and stress-relieving heat treatment capabilities

ISO 9001:2015 and ISO 13485:2016 certified

Expertise machining challenging high-performance plastics

CAD/CAM integration for rapid prototype-to-production

Secondary operations complementing molding and extrusion services

Get Started

Contact Pexco’s precision machining team to discuss your component requirements and machining specifications.