Our Products

Our Brands

Markets

Capabilities

About Pexco

Advanced Plastic Engineering

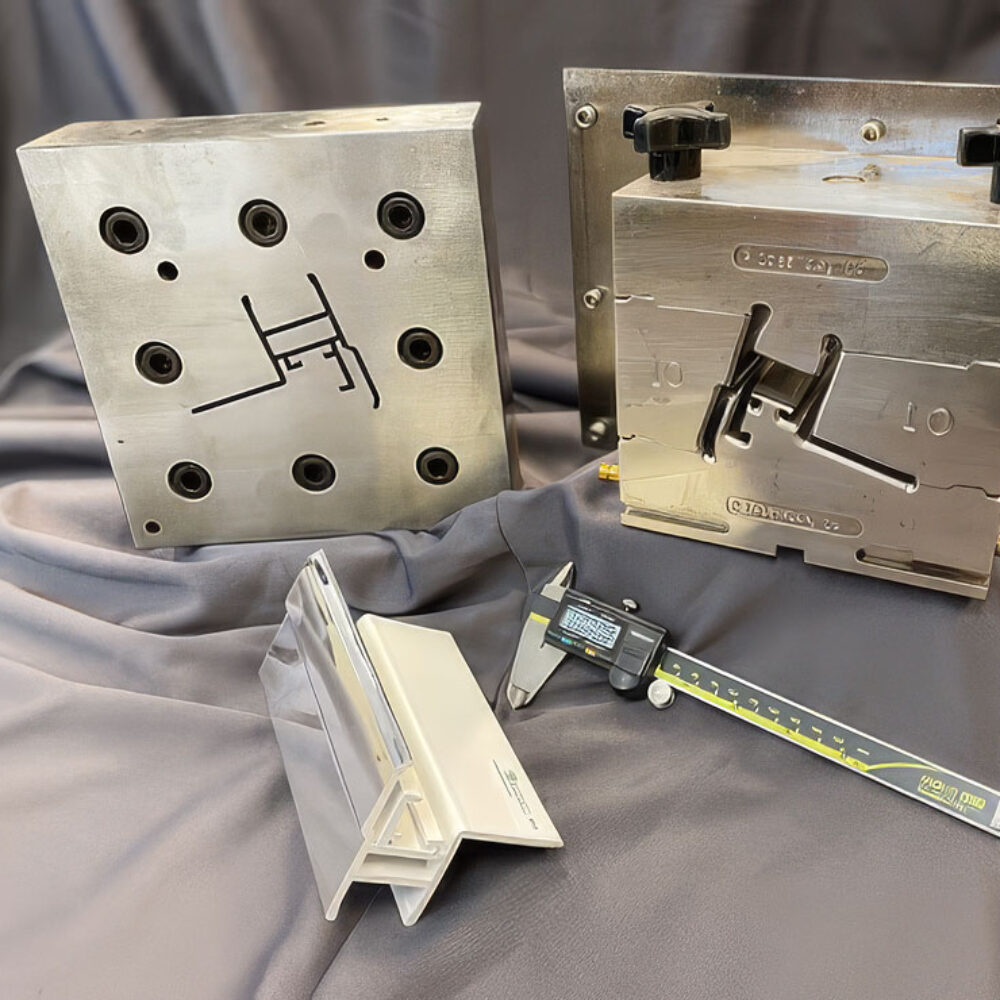

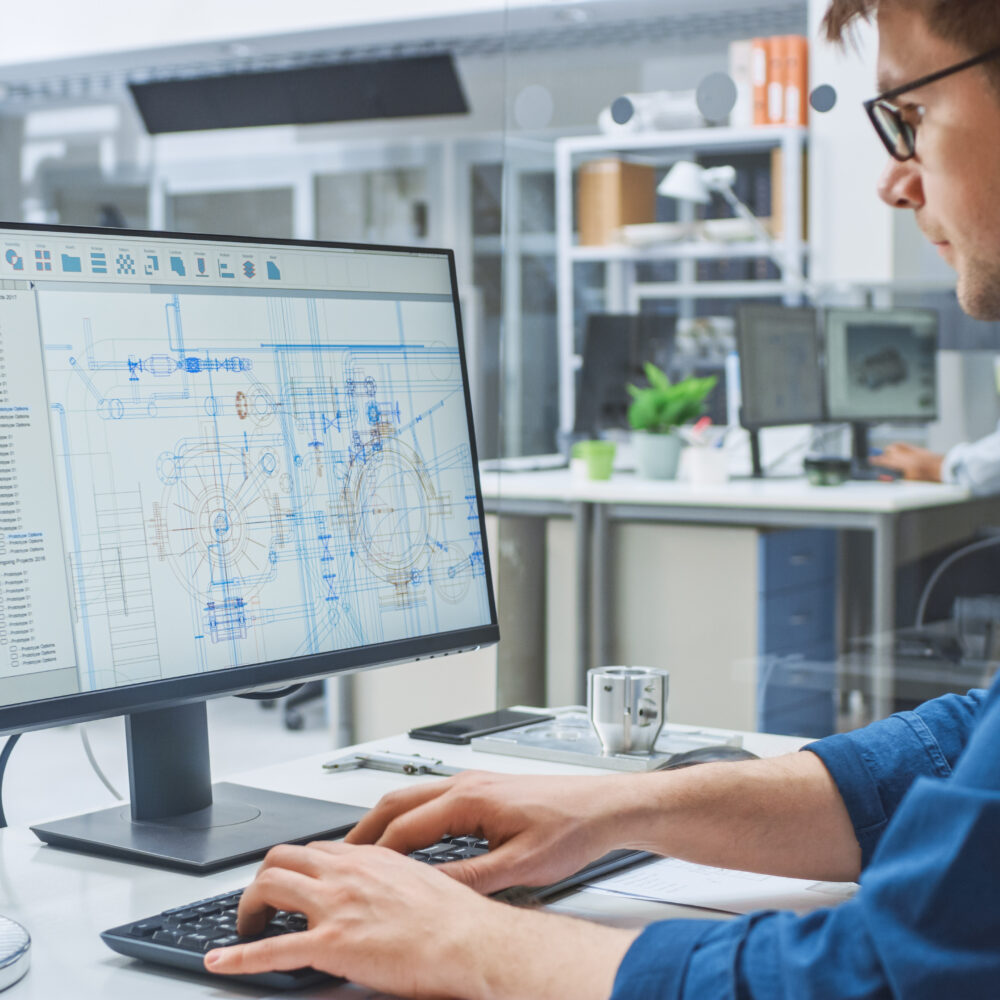

Design Engineering Services

Pexco’s engineering teams provide comprehensive technical support throughout the product development lifecycle—from feasibility analysis and material selection through tool design, prototype development, and production optimization. Our engineers specialize in high-performance thermoplastics, complex geometries, and tight-tolerance applications where material behavior, tooling strategy, and process parameters must align precisely to achieve required performance characteristics.

With decades of experience processing over 500 plastic resins across extrusion, injection molding, and compression molding, Pexco’s engineers translate application requirements into manufacturable designs that optimize performance, cost, and production efficiency.

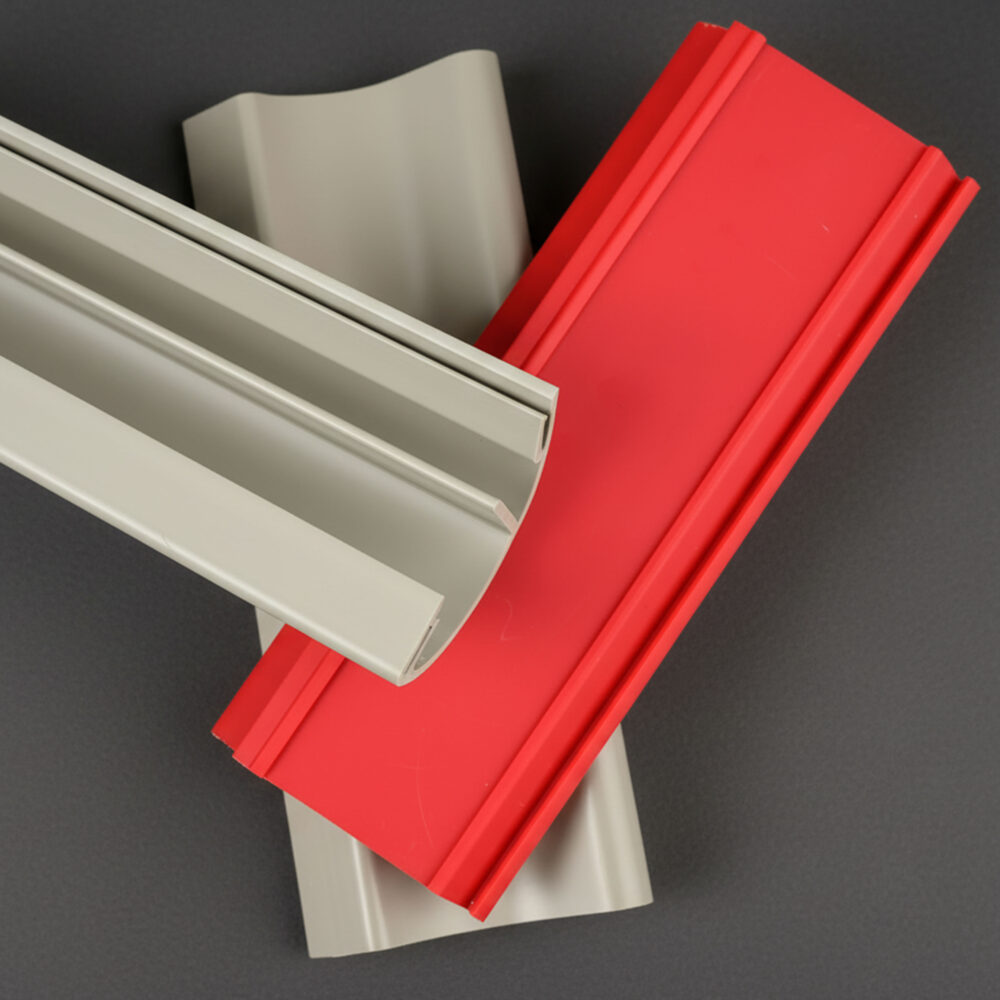

Design Optimization & CAD Modeling

Cross-sectional design and 3D modeling optimized for manufacturability across extrusion, injection molding, and compression molding processes. Our engineers work collaboratively with customers to refine designs, identifying potential manufacturing challenges and recommending modifications that improve quality, reduce cost, or accelerate production.

Design for Manufacturability (DFM) Analysis

Comprehensive DFM review identifies issues before tooling fabrication, including:

- Material flow and filling challenges in injection molding and compression molding

- Wall thickness variations and potential sink marks or voids

- Dimensional tolerance stackups and critical feature locations

- Draft angles, undercuts, and geometry that complicates demolding

- Extrusion profile cross-sections that may be unstable during cooling or difficult to calibrate

Material Selection & Application Engineering

Expert guidance on material selection across 500+ plastic resins, including ultra-high-performance thermoplastics (PEEK, PAI, PBI), fluoropolymers (PTFE, PFA, FEP, PVDF, ETFE), advanced engineering plastics (PSU, PEI, PPS), and filled/reinforced compounds. Our engineers consider multiple factors:

Performance Requirements

Thermal resistance, chemical compatibility, mechanical properties (tensile strength, impact resistance, flex modulus), electrical properties, UV stability, and flame retardancy.

Manufacturing Considerations

Processing temperature windows, mold shrinkage characteristics, flow properties for complex geometries, and compatibility with available manufacturing processes.

Regulatory & Compliance

FDA compliance for food contact or medical applications, UL ratings for electrical applications, aerospace specifications, and industry-specific material requirements.

Total Cost of Ownership

Material cost, processing efficiency, secondary operation requirements, and long-term performance versus less expensive alternatives that may require frequent replacement.

Process Engineering & Optimization

Scientific molding principles and data-driven process development ensure consistent part quality and production efficiency.

Process Parameter Development

Establishing optimal temperatures, pressures, speeds, and cycle times for each unique combination of material, tool design, and part geometry. Particularly critical for temperature-sensitive materials and tight-tolerance applications.

Production Optimization

Fine-tuning processes based on production data, quality feedback, and efficiency metrics. Continuous improvement programs identify opportunities to reduce cycle times, minimize scrap, and improve yield.

Troubleshooting & Root Cause Analysis

Investigating quality issues, dimensional variations, or production challenges using systematic problem-solving methodologies. Leveraging CT scanning, process monitoring data, and material testing to identify root causes and implement effective solutions.

Technical Documentation & Support

Comprehensive engineering documentation supports regulated industries and complex supply chains:

- Material specifications and certifications

- Process validation documentation

- Dimensional inspection reports

- Design change management and revision control

- Technical drawings and 3D CAD models

- Manufacturing work instructions

Collaborative Engineering Approach

Pexco’s engineers work as an extension of customer teams, participating in design reviews, providing technical recommendations, and supporting product development from concept through production. Whether customers arrive with complete designs requiring manufacturing optimization or preliminary concepts requiring full engineering support, Pexco adapts engineering involvement to project needs.

Related Capabilities

Get Started

Contact Pexco’s engineering team to discuss design optimization, material selection, or technical support for your project.