Our Products

Our Brands

Markets

Capabilities

About Pexco

Advanced Plastic Engineering

In-House Tooling & Die Manufacturing

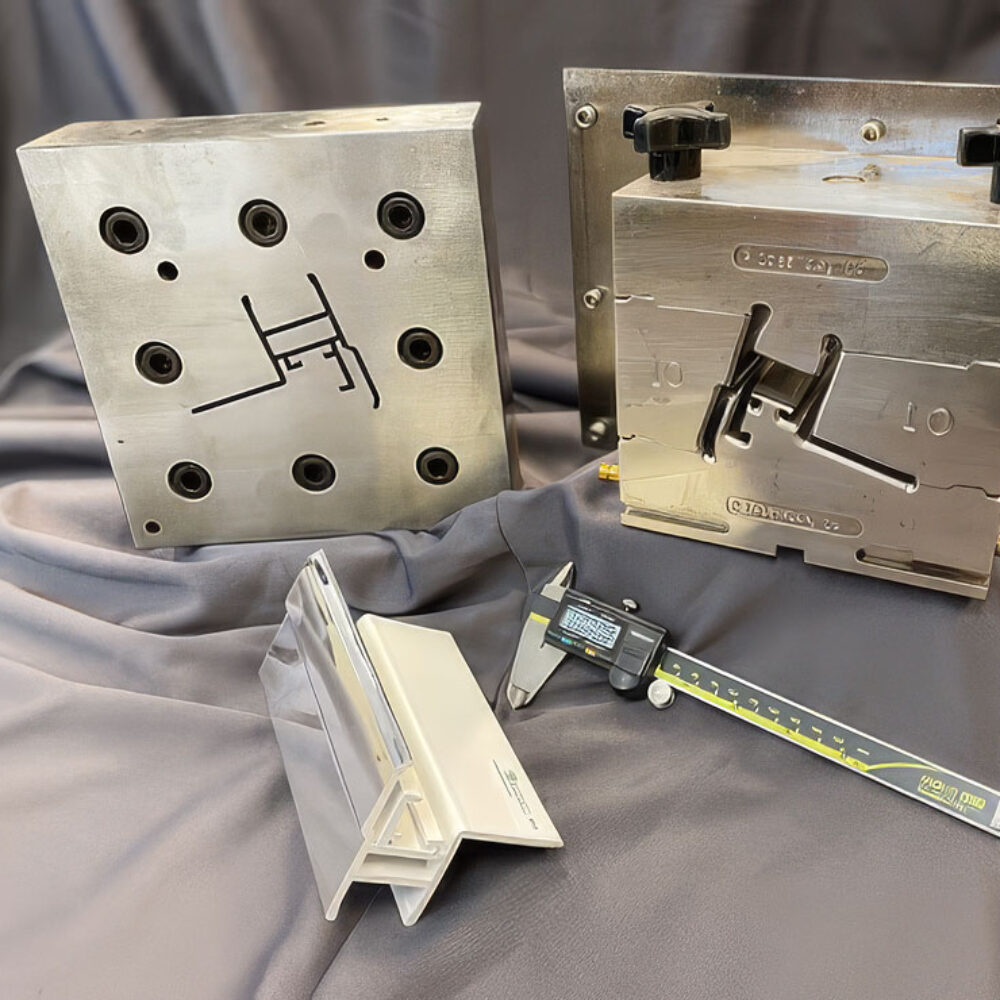

Pexco operates 6 dedicated tool and die centers across North America, providing complete control over tooling design, fabrication, and maintenance for extrusion, injection molding, and compression molding processes. This vertical integration eliminates outsourcing delays, protects proprietary designs, and enables rapid tool modifications during development and production—delivering significant competitive advantages for customers with complex geometries, challenging materials, or tight development timelines.

Our toolmakers have produced thousands of custom dies and molds for demanding applications ranging from miniature medical device components to large-scale architectural profiles. Decades of manufacturing experience are translated into optimized tooling designs specifically engineered for high-performance thermoplastics, fluoropolymers, filled compounds, and other challenging materials.

Strategic Advantages of In-House Tooling

No Outsourcing Delays

Direct control over tooling production schedules and priorities enables faster response times for new projects, modifications, and emergency repairs. When tooling issues arise during production, in-house capabilities eliminate vendor scheduling delays and enable immediate resolution—minimizing downtime and protecting delivery commitments.

Proprietary Tool Designs

Decades of practical manufacturing experience inform tooling designs optimized for specific processes, materials, and applications. Custom tooling platforms developed for challenging materials like fluoropolymers, ultra-high-performance thermoplastics, and filled compounds incorporate proprietary features that cannot be outsourced without losing competitive advantages.

Rapid Design Iterations

In-house modification capabilities enable quick adjustments during prototype development and production optimization. Design changes that would require weeks through external vendors can often be completed in days, accelerating new product introduction and reducing development costs.

Direct Engineering Collaboration

Tool designers work directly with process engineers, quality teams, and customers—ensuring tooling designs align with manufacturability requirements, production capabilities, and end-use performance criteria. This integration eliminates communication gaps and translation errors common with outsourced tooling.

Tooling Capabilities Across Processes

Pexco’s tool and die centers support the full range of manufacturing processes with specialized expertise for each application:

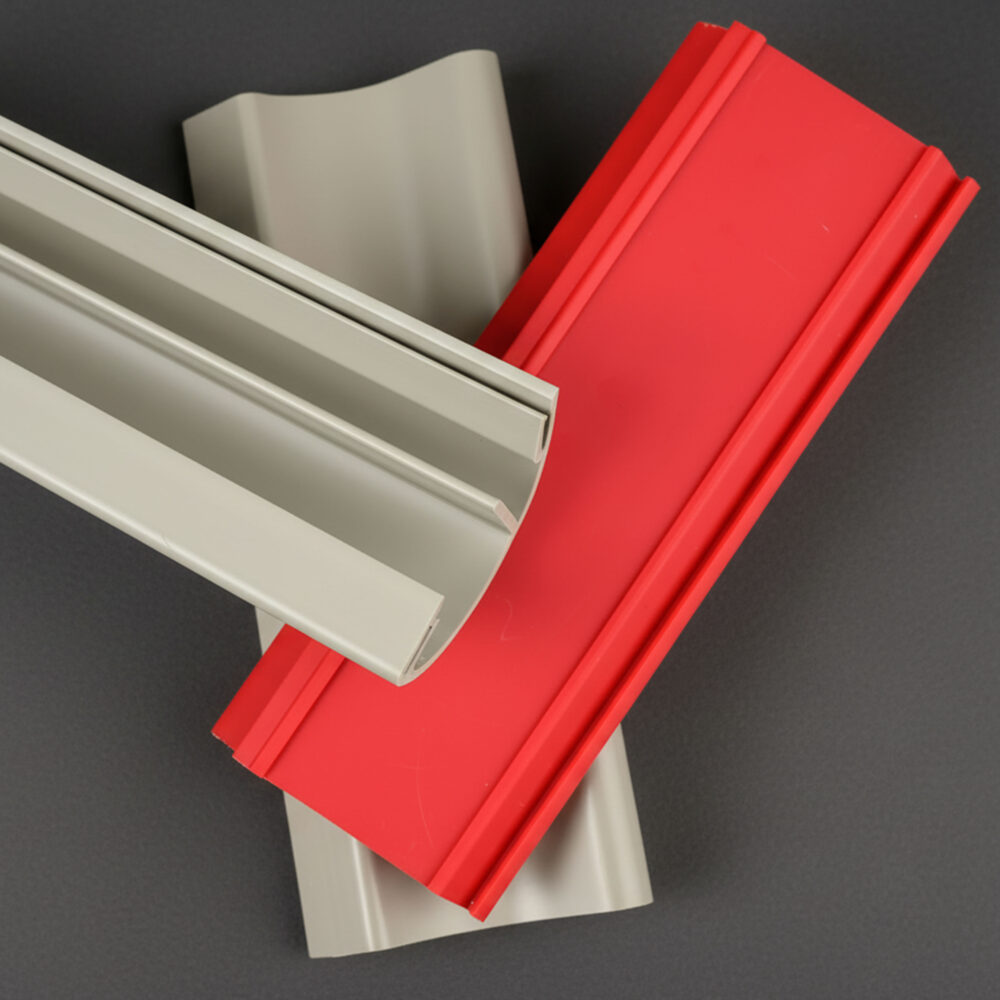

Extrusion Tooling

Custom dies for profiles ranging from 1/8″ miniature cross-sections to 30″+ wide large-scale extrusions. Fully streamlined stainless steel dies heat-treated for wear resistance and extended production life.

- Complex hollow profiles with multiple internal chambers

- Co-extrusion and tri-extrusion applications requiring precise material layer control

- Filled compounds (glass-filled, carbon-filled) requiring enhanced wear resistance

- High-temperature resins (PEEK, PAI, PEI) requiring specialized thermal management

- Celuka foam extrusion with controlled skin formation

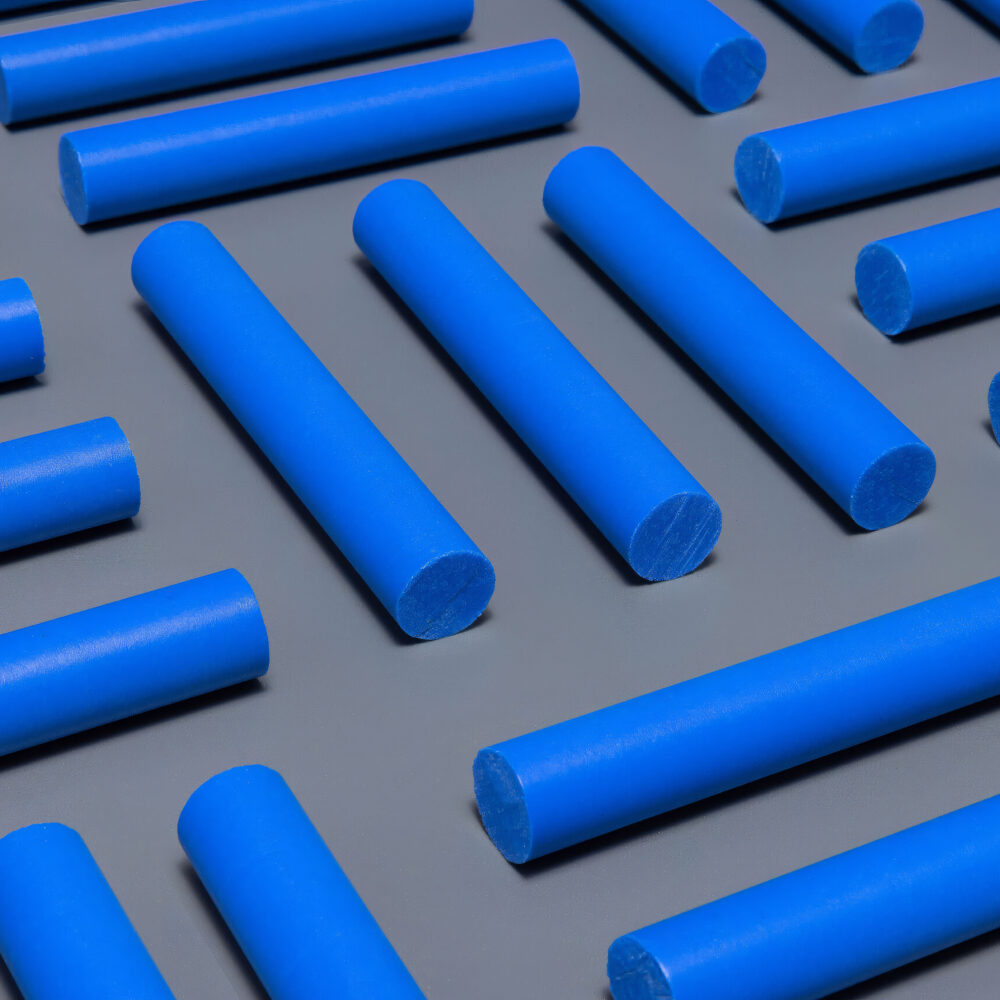

Injection Mold Tooling

Precision molds engineered for ultra-high-performance thermoplastics including fluoropolymers, PEEK, PAI, and PEI.

- Proprietary metallurgy and surface treatments for temperature-sensitive materials

- Thermal management strategies for materials requiring precise melt temperature control

- Family molds and hot runner systems for multi-cavity production

- Complex gating strategies for thin-walled components

- Net shape molding minimizing secondary operations

Compression & Transfer Mold Tooling

Tool design and fabrication for compression and transfer molding processes.

- Mold flow analysis for optimized tool design

- Tooling for both thermoset and thermoplastic compression molding

- Transfer molds for complex geometries requiring material flow contro

Custom Calibration & Sizing Equipment

Beyond dies and molds, Pexco designs and builds specialized process equipment:

Vacuum Calibration Systems

House-built vacuum calibration equipment specifically engineered for large-scale profile extrusions and complex hollow cross-sections. Custom-designed calibration blocks and vacuum zones optimized for specific profile geometries.

Sizing Equipment

Proprietary sizing and forming equipment for celuka foam extrusion, crosshead extrusion, and other specialized processes where standard equipment cannot achieve required dimensional control or surface quality.

Tool Maintenance & Modification

In-house capabilities extend throughout the tool lifecycle:

Preventive maintenance programs maximizing tool life

Rapid repair and refurbishment minimizing production downtime

Modification and optimization based on production data and quality feedback

Tool inspection and validation using CMMs and advanced metrology equipment

Documentation and revision control for regulated industries

Get Started

Contact Pexco’s engineering team to discuss custom tooling requirements for your application.