Our Products

Our Brands

Markets

Capabilities

About Pexco

Advanced Plastic Engineering

Industrial CT Scanning & Metrology

Pexco’s industrial computed tomography (CT) scanning capabilities provide non-destructive dimensional analysis, internal structure validation, and quality verification for complex plastic components. Using Zeiss metrology equipment, our engineers generate precise 3D models of parts and assemblies without destructive testing—enabling comprehensive inspection of internal features, wall thickness variations, voids, inclusions, and dimensional accuracy against CAD specifications.

This technology is critical for validating injection-molded components with tight tolerances, extruded hollow profiles with internal chambers, compression-molded parts with complex geometries, and any application where traditional measurement methods cannot access internal features or would damage the part being inspected.

Advanced 3D Metrology

Industrial CT scanning uses 360-degree X-ray technology to capture both external surfaces and internal structures in a single scan, creating detailed 3D digital models. The scanner rotates the part while acquiring X-ray data, which is then processed into a complete volumetric representation showing every internal and external feature.

This non-destructive approach is particularly valuable for:

- Failure analysis requiring complete internal examination

- Components with internal features inaccessible to traditional inspection methods

- Thin-walled parts where physical probing could cause damage or deformation

- Assemblies requiring validation of internal alignment and clearances

- First article inspection where destructive testing would eliminate critical samples

CT Scanning Capabilities

Part-to-CAD Comparisons

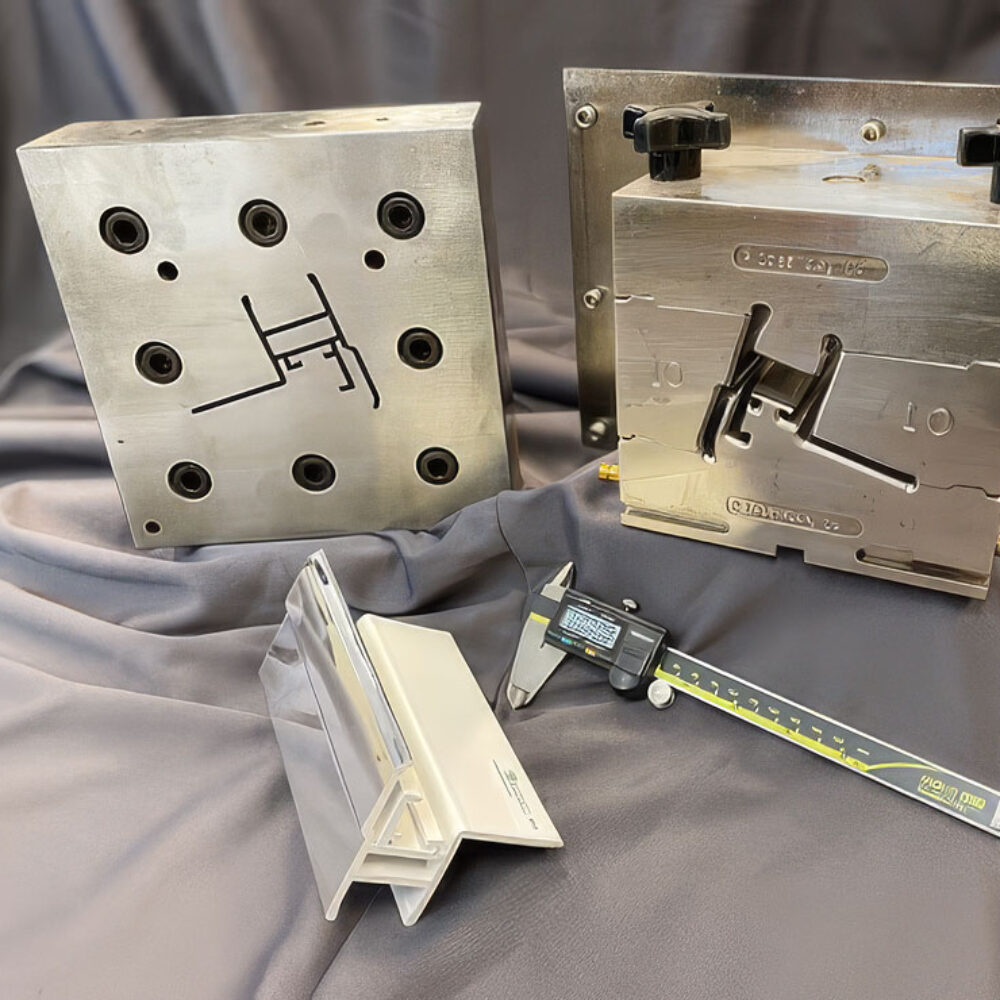

Precision overlay of scanned parts against original 3D CAD models generates color-mapped deviation reports. This identifies dimensional variations across the entire part surface, revealing areas of shrinkage, warpage, or deviation from design intent. Critical for validating new tooling, troubleshooting dimensional issues, and ensuring conformance to specifications.

Part-to-Part Comparisons

Overlay analysis of multiple scanned parts reveals dimensional variation between samples, production lots, or different tooling cavities. Particularly useful for identifying cavity-to-cavity variations in multi-cavity injection molds, comparing first articles to production parts, or validating consistency across manufacturing runs.

Void & Inclusion Analysis

Material defect detection showing void size, location, and distribution throughout the part volume. Critical for high-performance applications in aerospace, medical devices, and semiconductor equipment where internal voids compromise structural integrity, performance, or regulatory compliance. Also identifies foreign material inclusions, contamination, or incomplete material consolidation.

Wall Thickness Analysis

Non-destructive measurement of wall stock variations in complex parts, identifying thin sections, sink marks, or inconsistent material distribution that cannot be measured by external inspection alone. Particularly valuable for injection-molded components with ribs, bosses, and complex internal geometries where wall thickness directly impacts part performance and quality.

Dimensional Analysis

Full article inspection and reporting for components with tight tolerances. Capable of validating tolerances to ±0.001″ on injection-molded parts, with comprehensive dimensional reports documenting conformance across all critical features.

Reverse Engineering

3D CAD file generation from scanned parts enables replication, modification, or replacement of components without original design files. Useful for obsolescence management, legacy part reproduction, or competitive benchmarking.

Applications Across Manufacturing Processes

Industrial CT scanning supports quality validation throughout Pexco’s manufacturing capabilities:

Injection Molding

Thin-walled fluoropolymer components, multi-cavity tool validation, complex geometries with internal features, tight-tolerance medical and aerospace parts.

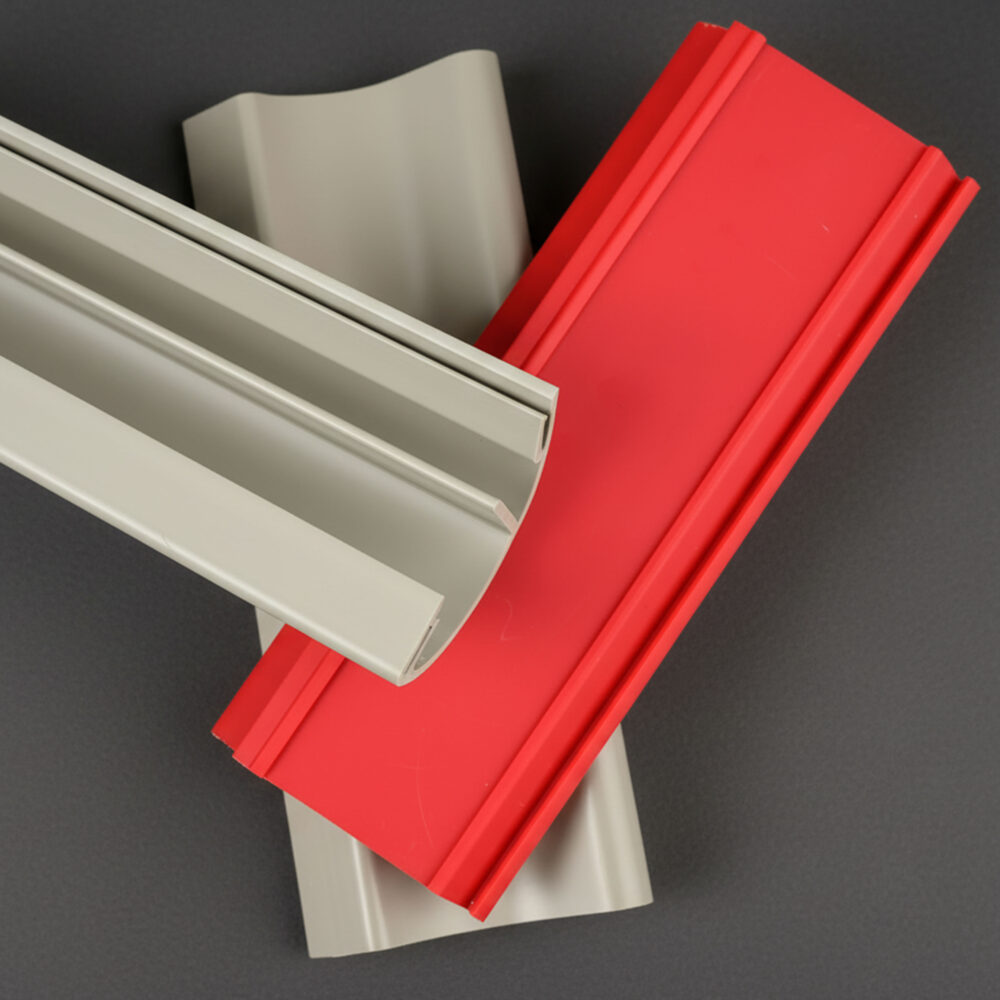

Profile Extrusion

Hollow profiles with multiple internal chambers, wall thickness validation on large-scale extrusions, internal geometry verification.

Compression Molding

Complex molded components, internal structure validation, void analysis in structural parts.

Assemblies

Multi-component assemblies requiring internal alignment verification, clearance validation, or fit analysis.

Quality Control Integration

CT scanning integrates into Pexco’s comprehensive quality systems:

- New product introduction and first article inspection

- Production process validation and capability studies

- Ongoing process monitoring and statistical process control

- Failure analysis and root cause investigation

- Supplier part validation and incoming inspection

- Customer-witnessed inspections and documentation

Get Started

Contact Pexco’s engineering team to discuss your technical requirements, material selection, or tooling challenges.