Our Products

Our Brands

Markets

Capabilities

About Pexco

Advanced Plastic Engineering

Vacuum Calibration Technology

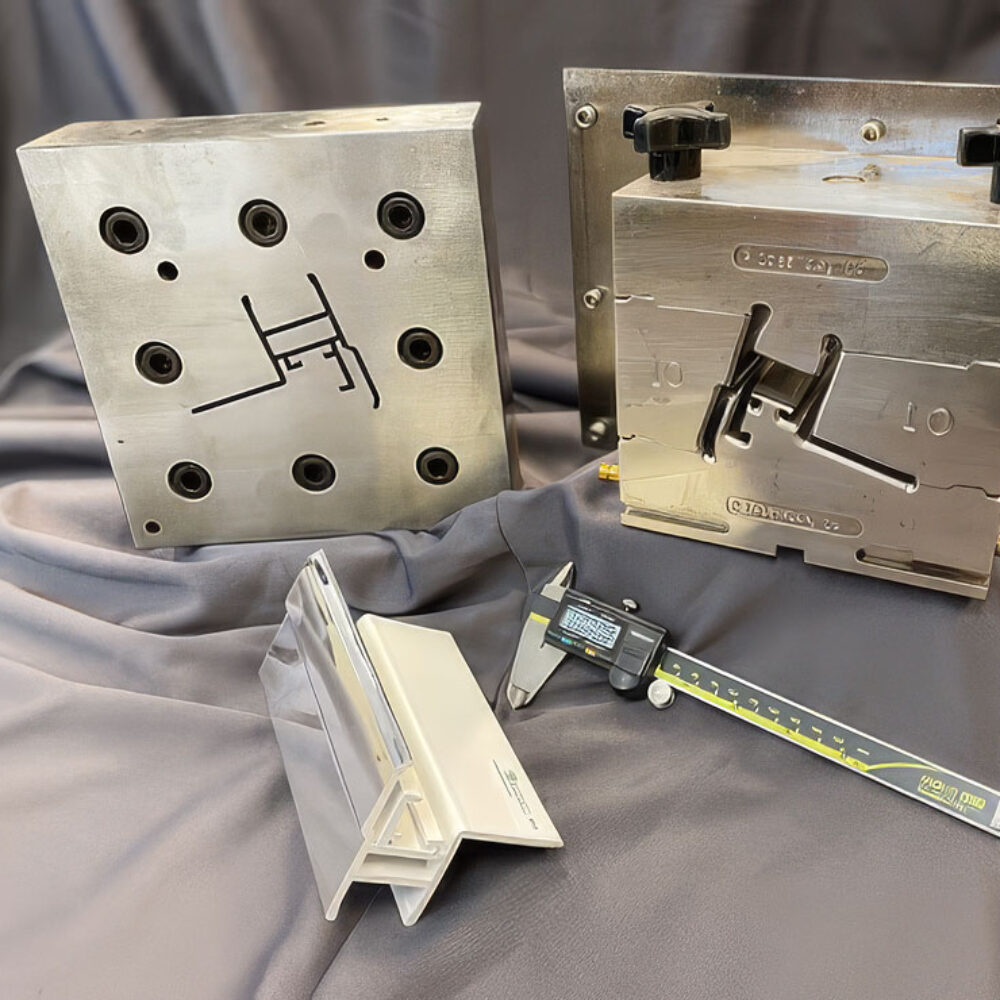

Pexco’s vacuum calibration systems deliver dimensional precision for complex extruded profiles, particularly large-scale and hollow cross-sections where conventional sizing methods cannot maintain tolerances. After exiting the extrusion die, the molten profile enters precision-machined calibration blocks where controlled vacuum pressure draws the material against the calibrator walls. The polymer solidifies under vacuum, ensuring tight dimensional control and exceptional shape consistency from part-to-part and run-to-run.

This technology is critical for producing profiles with intricate internal geometries, multiple chambers, and tight tolerances at scales that challenge traditional water bath cooling and sizing methods. Pexco has designed and built custom vacuum calibration equipment specifically engineered for large-scale profiles and demanding dimensional requirements.

Large-Scale Profile Calibration

House-built vacuum calibration equipment engineered specifically for profiles exceeding 30 inches in width and 6 inches in height. Our custom-designed systems accommodate complex cross-sections that cannot be produced on standard calibration equipment, enabling architectural profiles, structural components, and specialized industrial applications at unprecedented scale.

Complex Hollow Profile Calibration

Multi-chamber vacuum calibration maintains dimensional control on hollow profiles with intricate internal geometries. Precision internal mandrels and strategically placed vacuum zones control each chamber independently, ensuring accurate channel dimensions, cavity sizes, and wall thicknesses throughout complex cross-sections.

This capability enables hollow profiles with integrated features such as wiring channels, fluid routing passages, structural reinforcement cavities, and insulation chambers—all held to tight tolerances that would be impossible to achieve through external sizing alone.

Vacuum Calibration Benefits

Dimensional Stability & Repeatability

Excellent consistency across production runs with minimal part-to-part variation. Vacuum pressure ensures material conforms precisely to calibrator geometry, eliminating common sizing issues like ovality, warping, or dimensional drift.

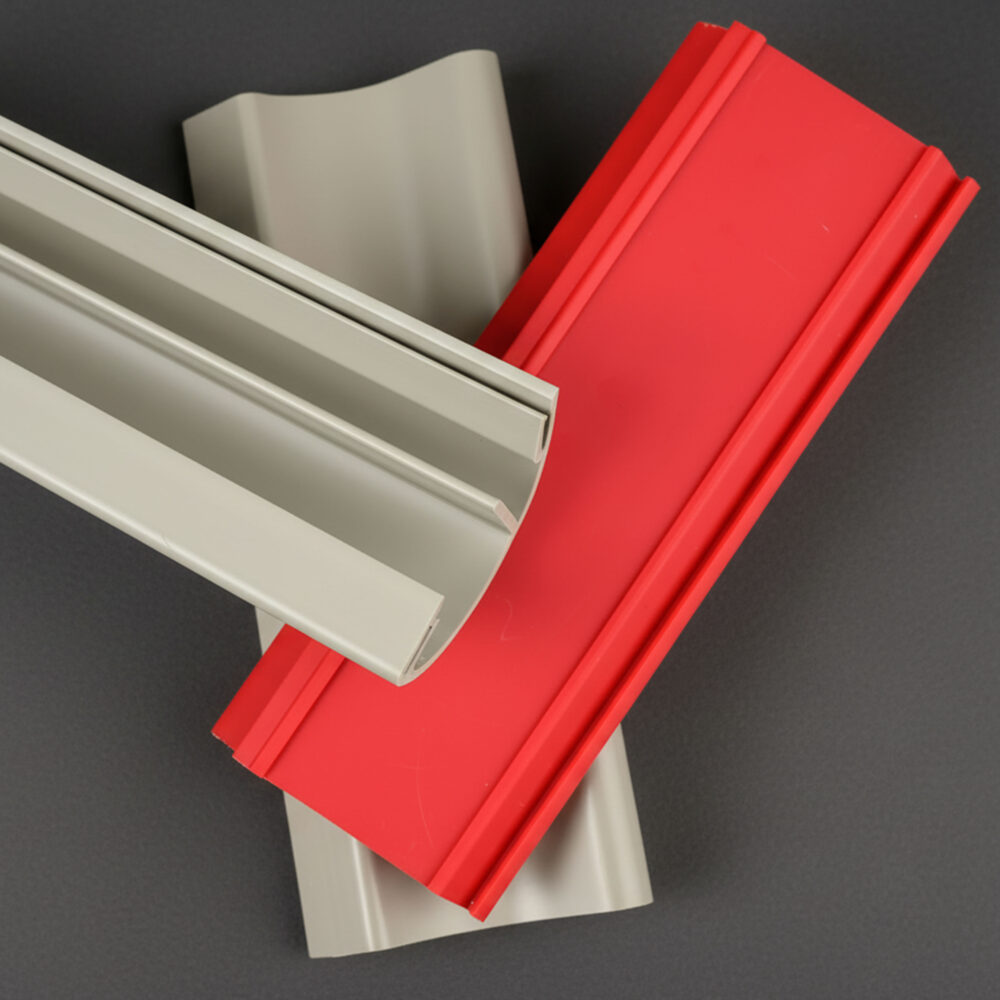

Superior Surface Finish

Controlled cooling against precision-machined calibrator surfaces produces excellent external surface quality. Particularly valuable for architectural and visible applications where appearance matters.

Complex Geometries

Capability to produce profiles with cross-sections that cannot be achieved through traditional sizing methods. Includes undercuts, tight internal corners, and features that require precise vacuum zone control.

Faster Line Speeds

Vacuum calibration enables higher production rates compared to water bath cooling alone. Controlled heat extraction and dimensional stability allow optimized line speeds without sacrificing quality.

Material Compatibility

Vacuum calibration technology works across a wide range of thermoplastic resins, with processing parameters optimized for each material family. Particularly effective for engineering-grade plastics and filled compounds where dimensional precision is critical.

Applications

Vacuum calibration enables production of profiles used in:

- Architectural and construction systems requiring precise tolerances

- Industrial profiles with integrated channels and cavities

- Large-scale structural components

- Specialty profiles for transportation and infrastructure

- Custom hollow extrusions for fluid management systems

Get Started

Contact Pexco’s engineering team to discuss your vacuum calibration requirements and profile specifications.