Our Products

Our Brands

Markets

Capabilities

About Pexco

Pexco Capabilities

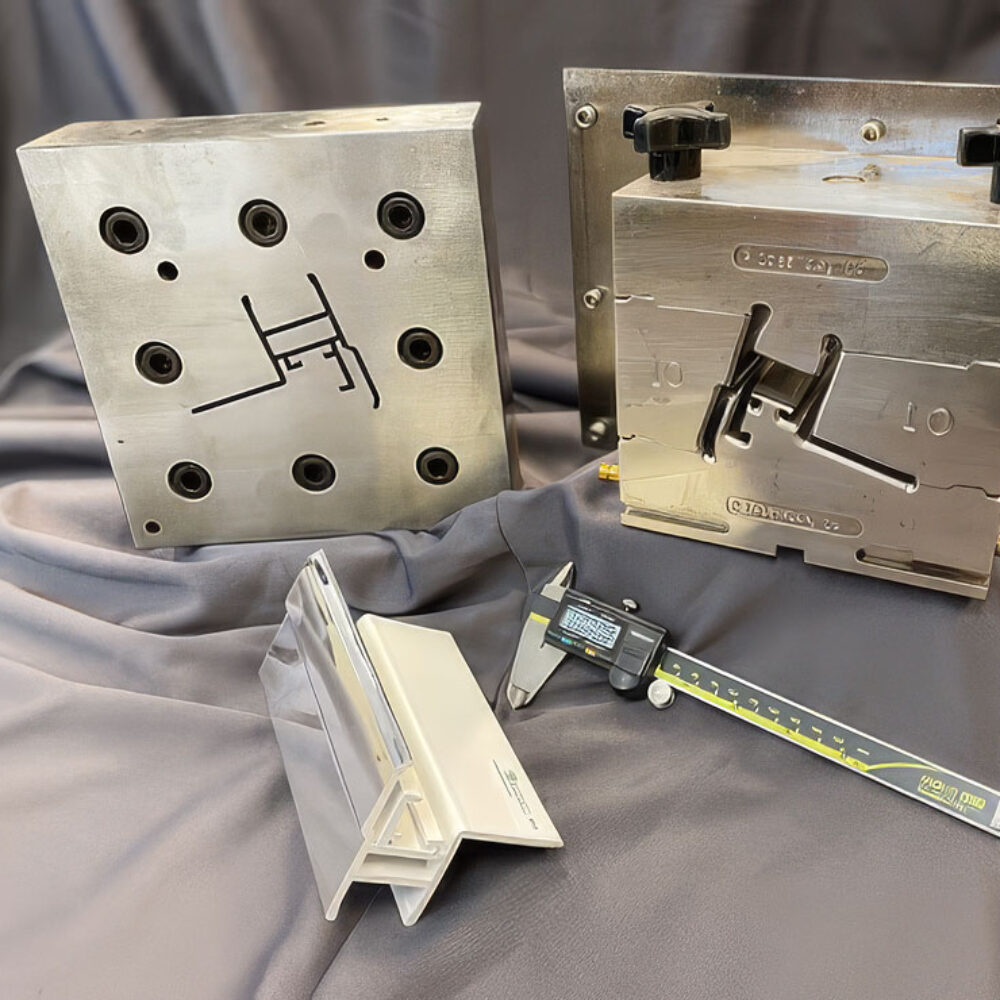

Injection Molding

Where Ideas Take Shape

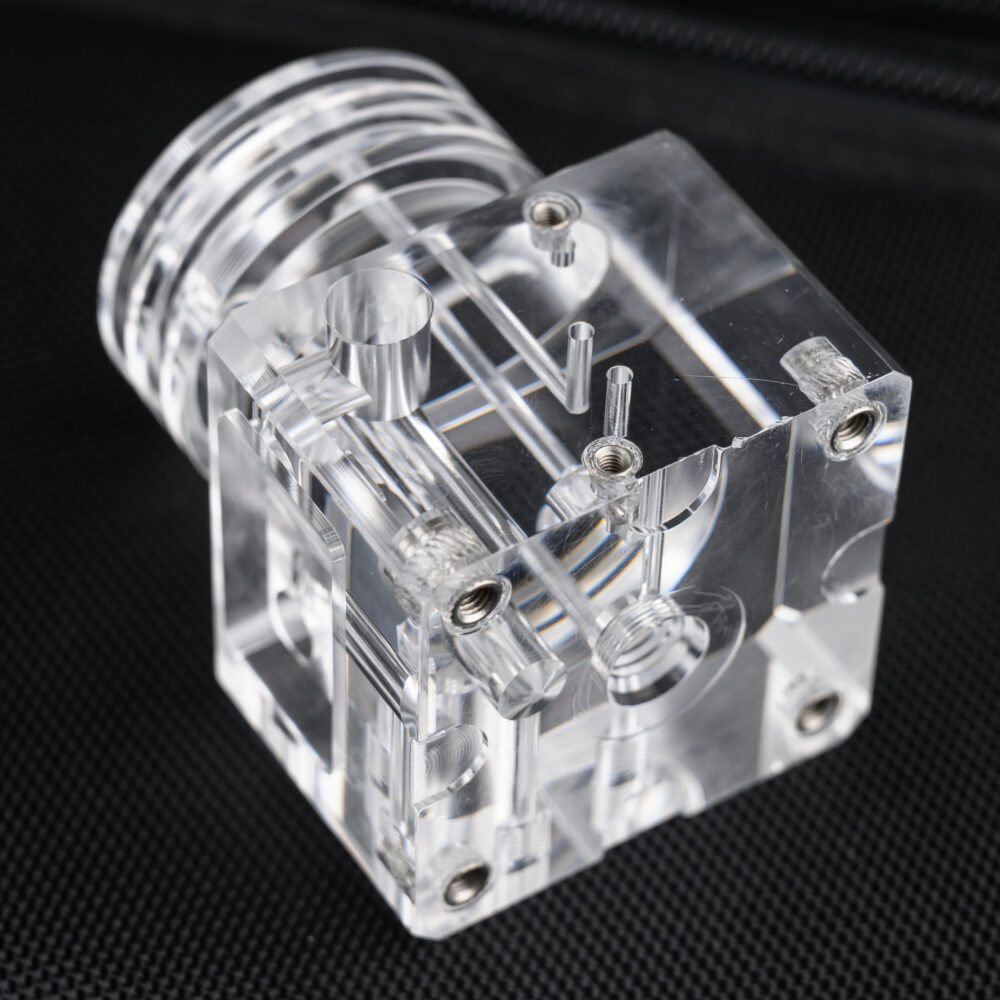

Pexco specializes in precision injection molding of ultra-high-performance thermoplastics for aerospace, medical, semiconductor, and industrial applications where failure is not an option. We excel at molding challenging materials like PEEK, PAI (Torlon), PEI (Ultem), and fluoropolymers (FEP, PFA, PVDF) into complex geometries with tolerances as tight as ±0.0003 inches.

Our proprietary tooling, advanced thermal management systems, and industrial CT scanning capabilities enable us to produce net shape components that eliminate secondary machining while meeting the most demanding dimensional requirements. From concept through production, our engineering team provides comprehensive design support, mold flow analysis, and iterative tool development to solve your most difficult molding challenges.

Net Shape Molding

Net shape molding produces injection-molded components that meet final dimensional specifications directly out of the mold, eliminating or significantly reducing secondary machining operations. Pexco’s proprietary iterative tool design process integrates industrial CT scanning with up to 1.2 million critical dimensional measurements to make precise tool modifications. This approach achieves tolerances as tight as ±0.0003 inches on complex geometries molded from high-performance materials.

By eliminating machining of critical surfaces, net shape molding preserves resin-rich surfaces, avoids micro-cracks from cutting tools, and reduces manufacturing cost while improving component strength and sealing performance. Ideal for seals, valve bodies, bearings, and other precision components requiring exceptional dimensional control.

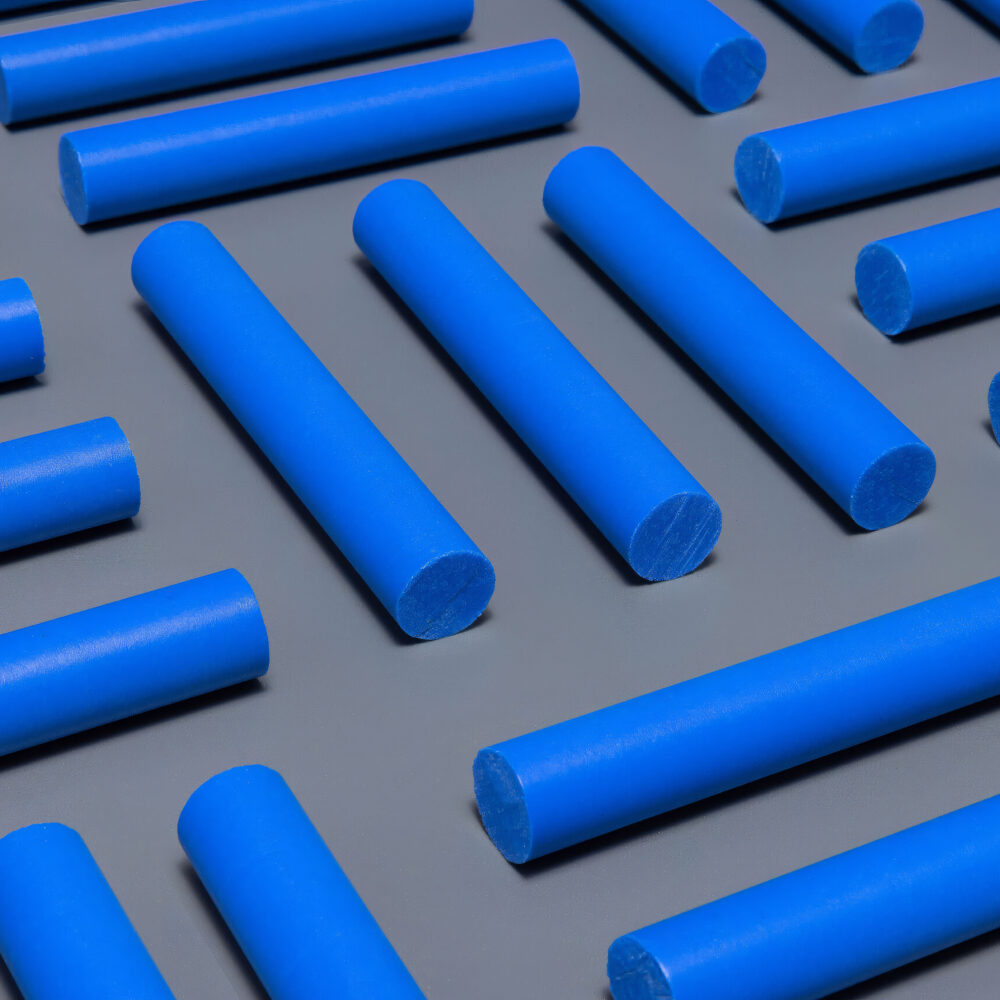

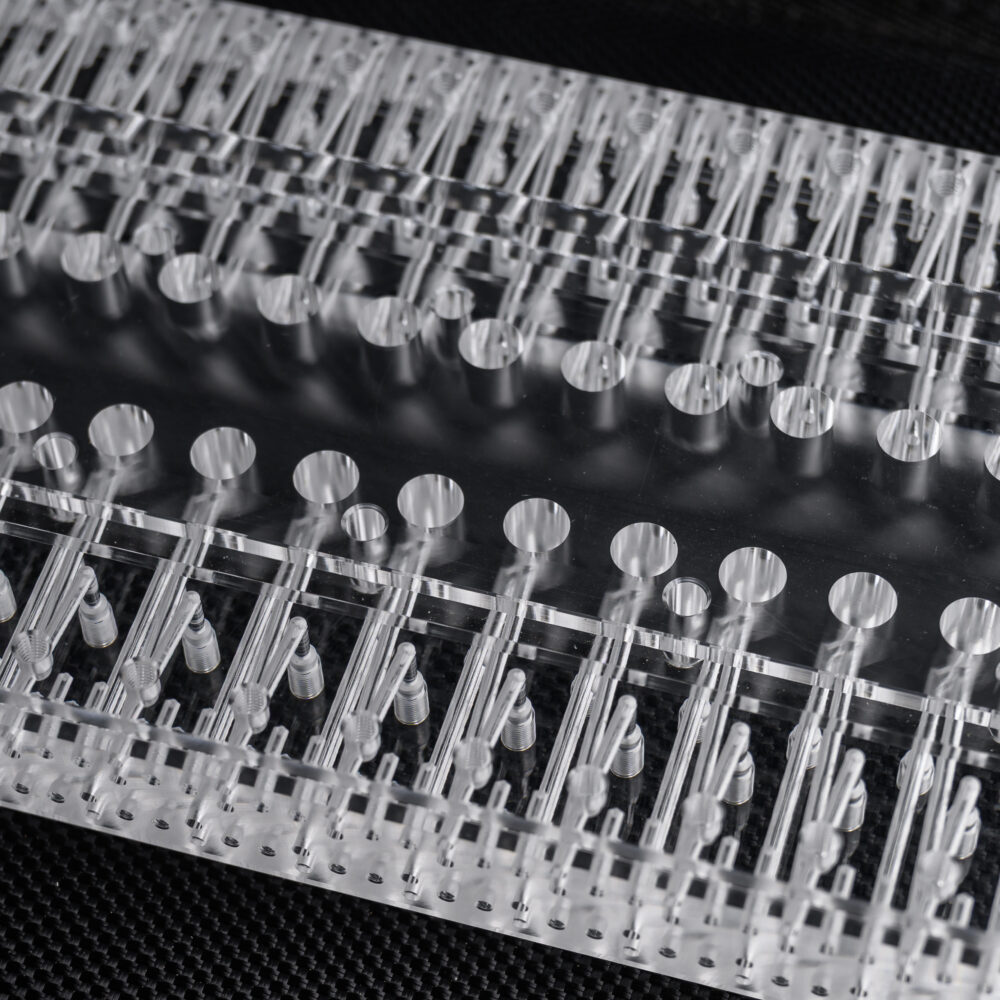

Direct Gating

Direct gating eliminates runner systems by injecting polymer directly into individual mold cavities, drastically reducing material waste and per-part cost when working with expensive high-performance plastics. This technique is particularly valuable for shear-sensitive fluoropolymers and other ultra-high-performance materials where conventional runner systems generate excessive shear stress and material scrap.

Pexco has developed proprietary equipment and processes that provide precise control of pressure and temperature within each cavity while minimizing shear from the injection screw. Our direct gating technology enables economical multi-cavity tooling for complex, thin-walled components molded from materials like FEP, PFA, PEEK, and PAI that would otherwise require cost-prohibitive single-cavity molds.

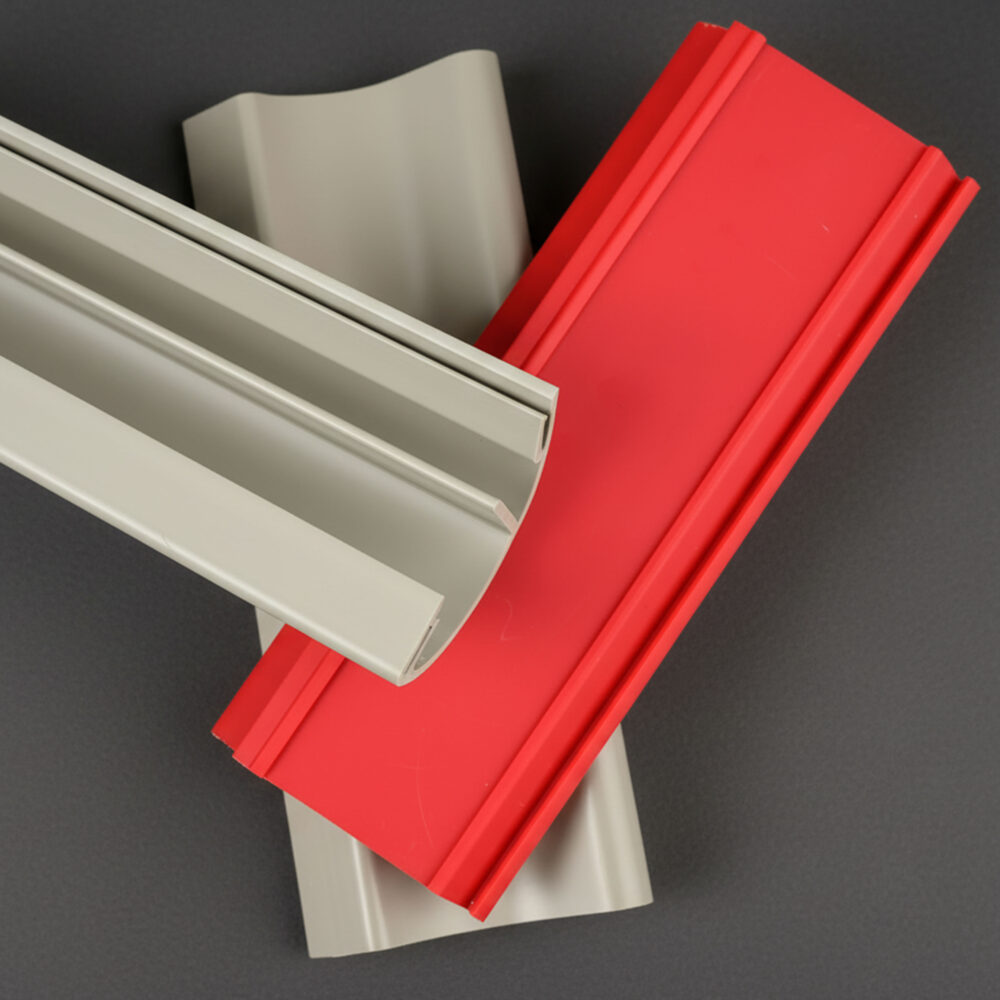

Fluoropolymer Molding

Pexco specializes in injection molding fluoropolymers including FEP, PFA, UHP PFA, PVDF, and ETFE for medical, pharmaceutical, semiconductor, and chemical processing applications. This requires extreme chemical resistance, thermal stability, and material purity. Fluoropolymers present unique molding challenges due to their low melt viscosity, high processing temperatures, and corrosive byproducts.

We have developed proprietary tooling using specialized mold steels resistant to hydrofluoric acid degradation, along with advanced thermal control systems and process refinements to successfully mold thin-walled, complex geometries. Our biocompatible fluoropolymer molding capabilities support medical device manufacturers requiring components like catheters, connectors, seals, and implantable devices that meet stringent regulatory standards.

Overmolding & Insert Molding

Overmolding and insert molding combine multiple materials into integrated components that eliminate assembly operations and enable designs not achievable through single-material molding. Pexco’s proprietary tooling designs and robotic placement systems enable us to mold around delicate inserts and complex geometries that other molders consider too thin or intricate to process reliably.

Unlike molders limited to commodity elastomers, we overmold with high-performance thermoplastics including PEEK, Ultem, and fluoropolymers. Our capabilities include metal insert molding with brass, steel, and stainless steel components, as well as multi-shot plastic-on-plastic overmolding for applications requiring multiple material properties in a single component.

Materials & Resins

Pexco injection molds a comprehensive range of high-performance thermoplastics:

Imidized Polymers

PAI (Torlon), PBI

Advanced Fluoropolymers

FEP, PFA, HP PFA, UHP PFA, PVDF, ETFE

Advanced Thermoplastics

PEEK, PEI (Ultem), PSU (Polysulfone), PPS (Ryton), EXTEM

General Plastics (Engineering Grade)

PU (Polyurethane), PA (Nylon), PC/PBT

Commodity Plastics

PVC/FPVC/RPVC, LLDPE, Polycarbonate

Custom & Filled Materials

Glass-filled, carbon-filled, mineral-filled, custom color matching

Why Choose Pexco?

Tolerances as tight as ±0.0003″ on net shape molded components

Proprietary iterative tool design with industrial CT scanning verification

Direct gating technology for multi-cavity fluoropolymer molding

Advanced overmolding and insert molding for delicate, complex assemblies

6 in-house tool and die centers with mold design and fabrication capabilities

Industrial CT Scanning with Zeiss equipment for non-destructive dimensional verification

Design Engineering Services from concept through production

ISO 9001:2015 certified, ITAR registered

Family molds, hot runner systems, and complex gating strategies

Biocompatible fluoropolymer molding for medical device applications

Robotic part handling and automated vision inspection

Get Started

Contact Pexco’s engineering team to discuss your technical requirements, material selection, or tooling challenges.