Our Products

Our Brands

Markets

Capabilities

About Pexco

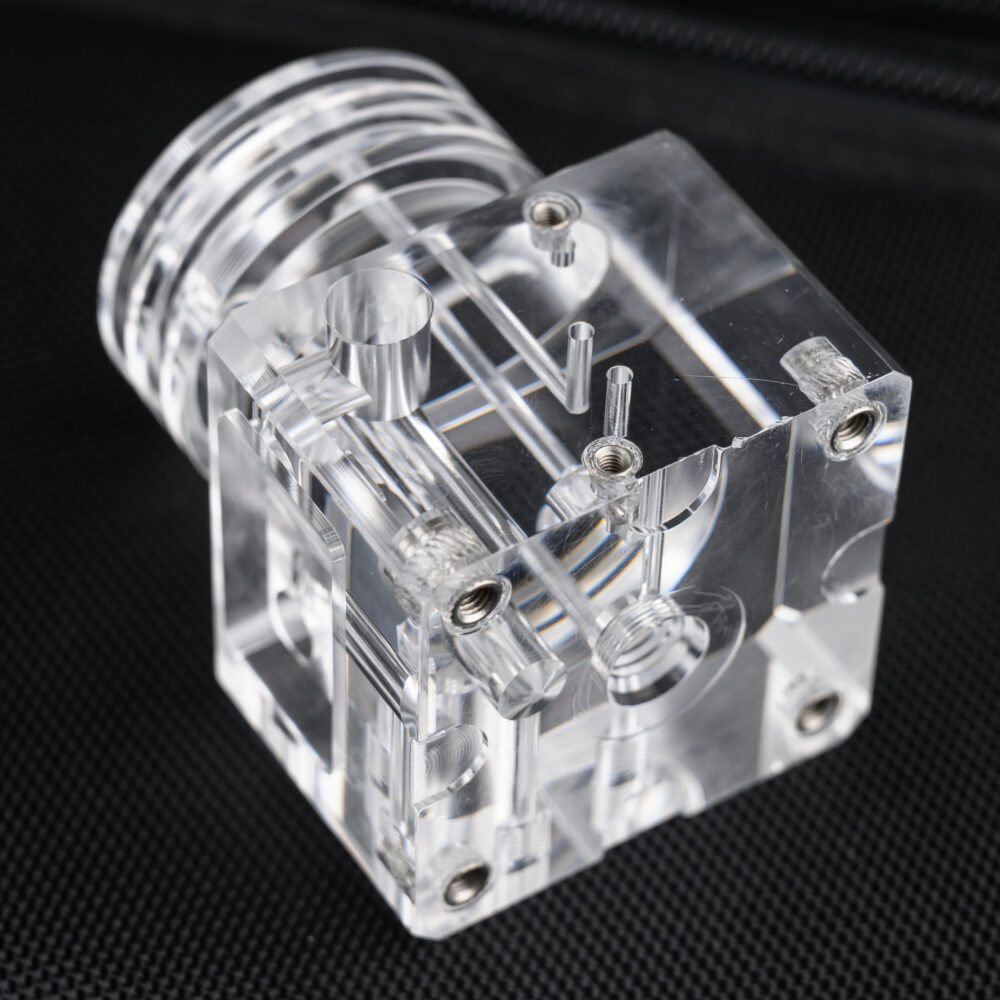

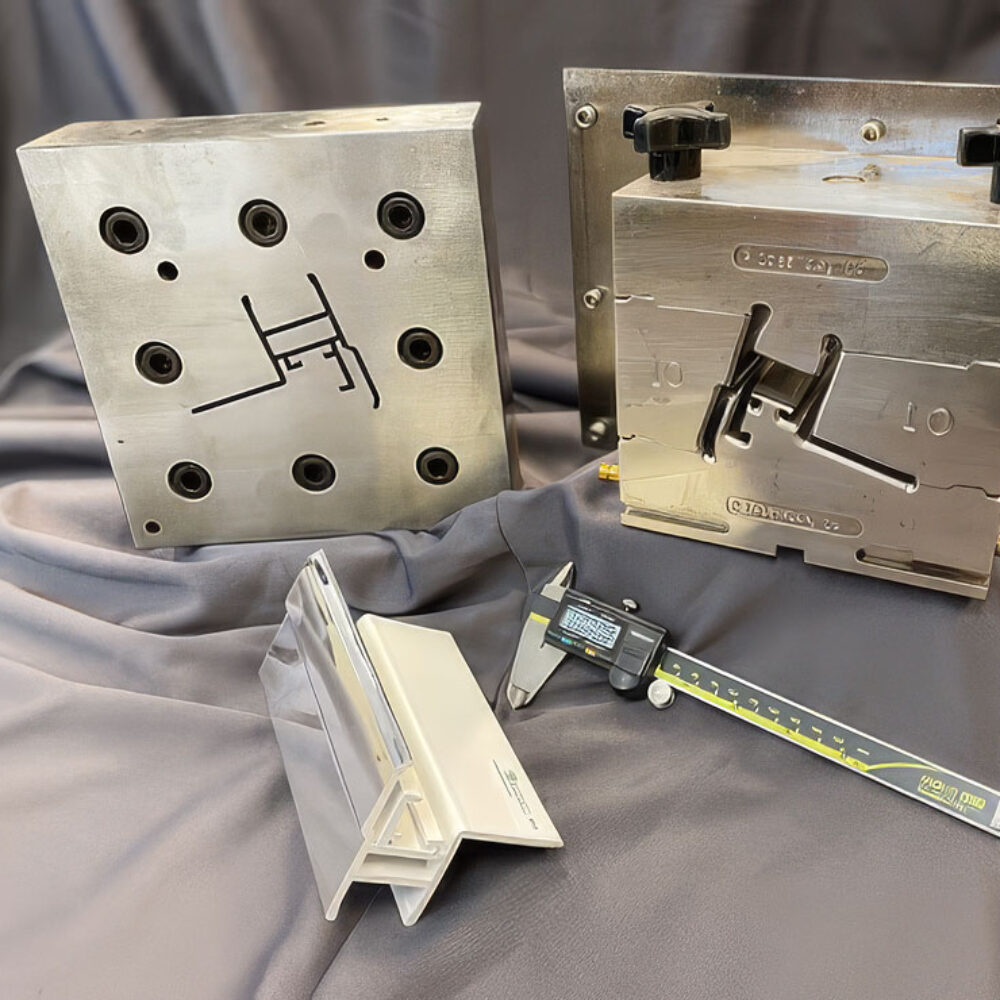

Injection Molding

Direct Gating

Where Ideas Take Shape

Direct gating eliminates traditional runner systems by injecting polymer directly into individual mold cavities, drastically reducing material waste and per-part cost when working with expensive high-performance plastics. This technology proves essential for economical production of components molded from shear-sensitive fluoropolymers and other ultra-high-performance materials where conventional runner systems generate excessive material scrap and degradation.

Pexco has developed proprietary equipment and molding processes that enable multi-cavity direct gating with precise control of pressure and temperature in each cavity, making complex thin-walled geometries economically viable in materials like FEP, PFA, PEEK, and PAI.

Runner Elimination Technology

Conventional injection molding uses runner systems to distribute molten polymer from the injection unit to multiple mold cavities. These runners represent pure material waste that must be reground and reprocessed, or in the case of many high-performance materials, discarded entirely. For fluoropolymers, PEEK, and other expensive resins costing $50-200+ per pound, runner waste can make multi-cavity tooling economically impractical despite the production efficiency benefits.

Direct gating solves this by injecting polymer directly into the part cavity, eliminating the runner entirely. This approach:

- Reduces material consumption by 30-60% depending on part geometry and cavity count

- Lowers per-part cost making high-performance materials economically competitive with lower-grade alternatives

- Minimizes material degradation from repeated heating cycles required for regrind processing

- Enables multi-cavity tooling for parts that would otherwise require cost-prohibitive single-cavity molds

- Improves cycle consistency by eliminating variables associated with runner freeze-off and regrind contamination

Shear-Sensitive Material Processing

Fluoropolymers like FEP and PFA present unique molding challenges due to their extremely low melt viscosity and sensitivity to shear stress. Conventional injection molding subjects these materials to high shear rates as polymer flows through the auguring screw, runner system, and gate restrictions. Excessive shear can cause melt fracture, surface defects, and degradation of mechanical properties.

Pexco’s direct gating technology incorporates proprietary equipment modifications that drastically reduce shear-induced damage:

- Modified injection systems minimizing shear from the auguring screw

- Thermal control maintaining precise temperature in each cavity to optimize flow characteristics

- Pressure management balancing fill rates across multiple cavities while avoiding overpacking

- Specialized gate geometries optimized for low-viscosity materials

This approach allows us to successfully mold thin-walled, intricate fluoropolymer components using 8-cavity and higher multi-cavity molds with hot runner systems, capabilities that few molders can achieve with these challenging materials.

Multi-Cavity Tooling Economics

Direct gating fundamentally changes the economics of high-performance polymer molding. Consider a complex FEP component requiring 2 ounces of material per part. In a conventional 4-cavity mold, the runner system might add 6-8 ounces of additional material per shot. At $80/pound for virgin FEP, the runner waste costs $3-4 per shot while the actual parts cost only $5, making the process economically marginal.

With direct gating, the same 4-cavity mold consumes only the 8 ounces for actual parts, eliminating the runner waste entirely. This material savings justifies the higher initial tooling investment and enables economical production volumes that wouldn’t be viable with conventional molding approaches.

Design Considerations

Parts optimized for direct gating benefit from specific design considerations. Our engineering team works with customers to evaluate gate locations that minimize visible gate witness marks on cosmetic surfaces while ensuring proper cavity filling. For applications requiring clean edges and minimal post-processing, we develop gating strategies that position gates on non-critical surfaces or incorporate automated degating systems.

Wall thickness, flow length, and part complexity all influence direct gating feasibility. See Design Engineering Services for comprehensive design support including mold flow analysis and design for manufacturability reviews optimized for direct gating applications.

Materials & Resins

Pexco’s direct gating capabilities support high-performance materials where cost reduction is critical:

Imidized Polymers

FEP, PFA, HP PFA, UHP PFA, PVDF, ETFE – Primary applications for direct gating due to high material costs and shear sensitivity

Advanced Fluoropolymers

PEEK, PEI (Ultem), PSU (Polysulfone), PPS (Ryton) – Economical multi-cavity production of complex geometries

Imidized Polymers

PAI (Torlon), PBI – Cost reduction for high-volume production

Why Choose Pexco?

Proprietary direct gating equipment and process development

Multi-cavity tooling (8+ cavities) for shear-sensitive fluoropolymers

30-60% material cost reduction vs. conventional runner systems

Precise pressure and temperature control in individual cavities

Hot runner systems for high-volume production

Thin-walled, complex geometries in challenging materials

6 in-house tool and die centers for direct gating mold design

ISO 9001:2015 certified, ITAR registered

Get Started

Contact Pexco’s engineering team to discuss custom tooling requirements for your application.