Our Products

Our Brands

Markets

Capabilities

About Pexco

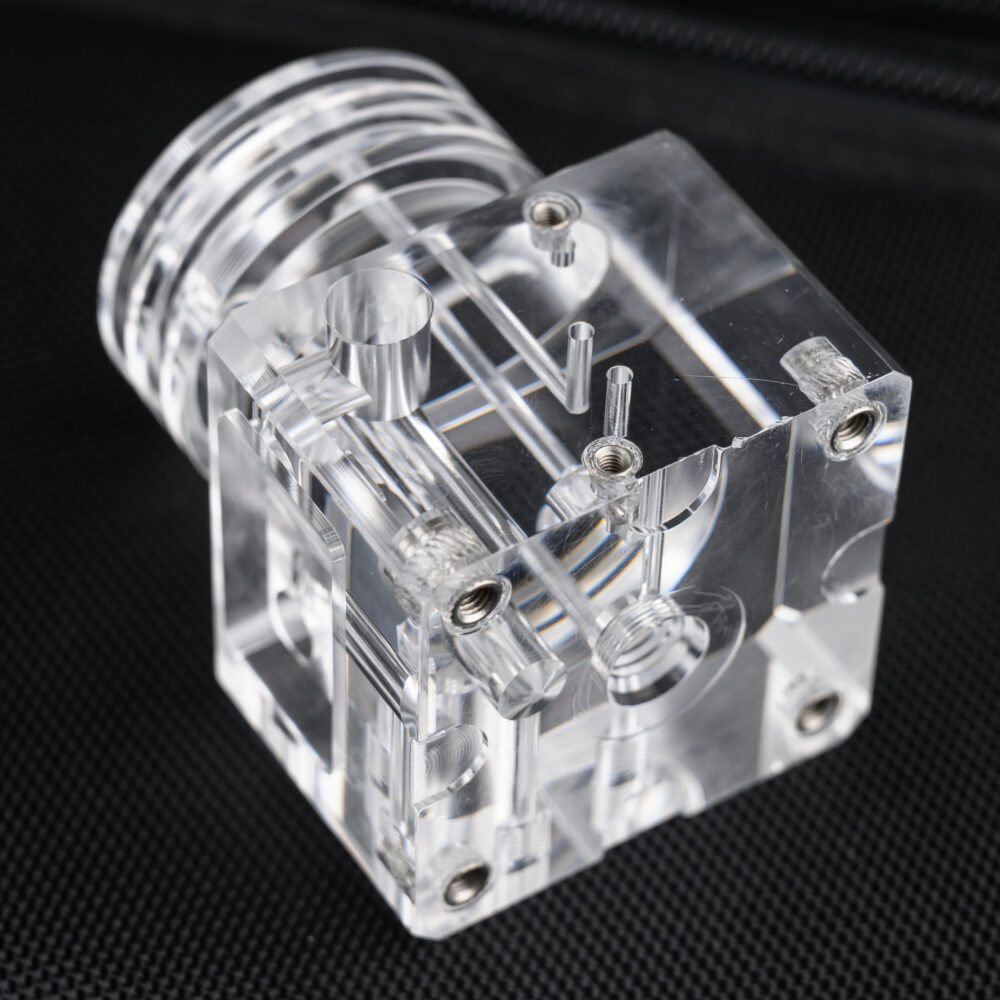

Injection Molding

Net Shape Molding

Where Ideas Take Shape

Net shape molding produces injection-molded components that achieve final dimensional specifications directly out of the mold, eliminating or minimizing secondary machining operations. This approach preserves critical surface integrity, reduces manufacturing costs, and improves component performance by maintaining resin-rich surfaces free from micro-cracks and fiber exposure caused by machining.

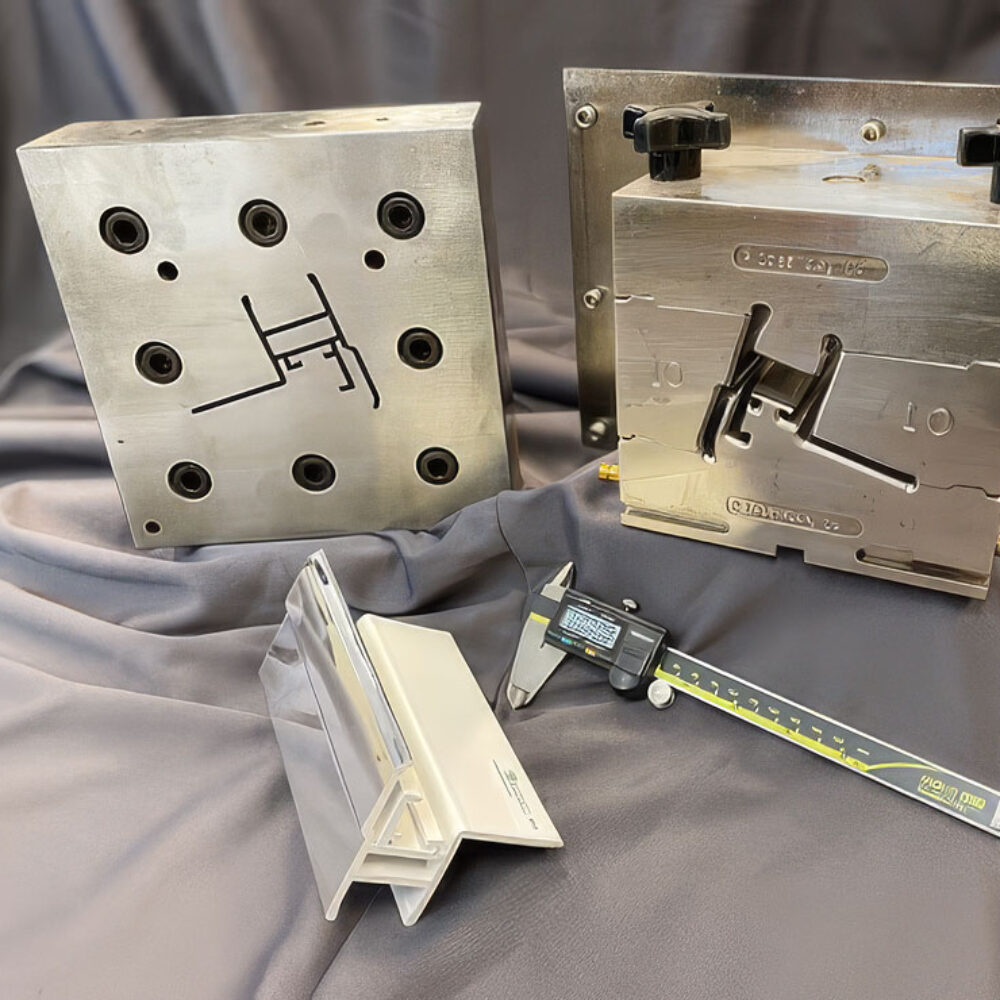

Pexco’s proprietary iterative tool design process integrates industrial CT scanning with precision measurements to achieve tolerances as tight as ±0.0003 inches on complex geometries molded from ultra-high-performance materials like PEEK, PAI (Torlon), and fluoropolymers.

Proprietary Iterative Tool Design

Pexco has developed a systematic approach to net shape molding that combines advanced software tools with iterative physical testing and tool modification:

Mold flow and finite element analysis

to predict material behavior and optimize gating, cooling, and part geometry

Initial tool design

incorporating decades of processing knowledge for high-performance thermoplastics, accounting for material shrinkage, thermal expansion, and process-induced stresses

CT scanning measurement

integrating CT data with CAD/CAM software to identify precise areas requiring tool modification

True form sizing technology

integrating CT data with CAD/CAM software to identify precise areas requiring tool modification

Iterative refinement cycles

continuing until parts consistently meet all dimensional specifications directly from the mold

This approach allows our engineering team to make highly targeted tool modifications rather than relying on traditional trial-and-error methods. For critical sealing surfaces, bearing interfaces, and precision mating features, this level of dimensional control enables us to achieve tolerances that would be impossible through conventional molding followed by secondary machining. See [Industrial CT Scanning & Metrology] for detailed capabilities.

Insert Molding Integration

Net shape molding techniques extend to insert molding applications where metal components, sensors, or other substrates integrate into the molded part. Our proprietary tooling and thermal management systems ensure proper polymer flow around insert features while maintaining dimensional stability of both the insert and surrounding geometry.

For comprehensive overmolding capabilities including delicate insert handling, multi-material combinations, and robotic placement systems, see Overmolding & Insert Molding.

Design for Manufacturability

Pexco’s engineering team provides comprehensive design support for net shape molding from concept through production, including mold flow analysis, finite element analysis, and design for manufacturability reviews. We optimize part geometries with appropriate draft angles, wall thickness transitions, and feature locations that support consistent dimensional control. Our 6 in-house tool and die centers handle mold design, fabrication, and rapid modifications throughout the development process. See Design Engineering Services and In-House Tooling & Die Manufacturing for complete capabilities.

Materials & Resins

Pexco’s net shape molding capabilities support the most demanding high-performance thermoplastics:

Imidized Polymers

PAI (Torlon), PBI – For extreme temperature and wear resistance applications

Advanced Fluoropolymers

FEP, PFA, HP PFA, UHP PFA, PVDF, ETFE – For chemical resistance and ultra-high purity requirements

Advanced Thermoplastics

PEEK, PEI (Ultem), PSU (Polysulfone), PPS (Ryton), EXTEM – For structural components requiring high strength and thermal stability

Custom & Filled Materials

Glass-filled, carbon-filled, mineral-filled compounds optimized for dimensional stability

Why Choose Pexco?

Tolerances as tight as ±0.0003 inches on net shape molded components

Proprietary iterative tool design process with CT scanning verification

Up to 1.2 million dimensional measurements per part for tool refinement

Eliminates secondary machining while improving component performance

Preserves resin-rich surfaces for enhanced strength and sealing capabilities

6 in-house tool and die centers for rapid tool modifications

Advanced insert molding for complex assemblies

ISO 9001:2015 certified, ITAR registered

Full design support from concept through production

Get Started

Contact Pexco’s net shape molding team to discuss how our proprietary iterative tool design process can eliminate secondary operations and improve your component performance.