Our Products

Our Brands

Markets

Capabilities

About Pexco

Injection Molding

Overmolding/Insert Molding

Where Ideas Take Shape

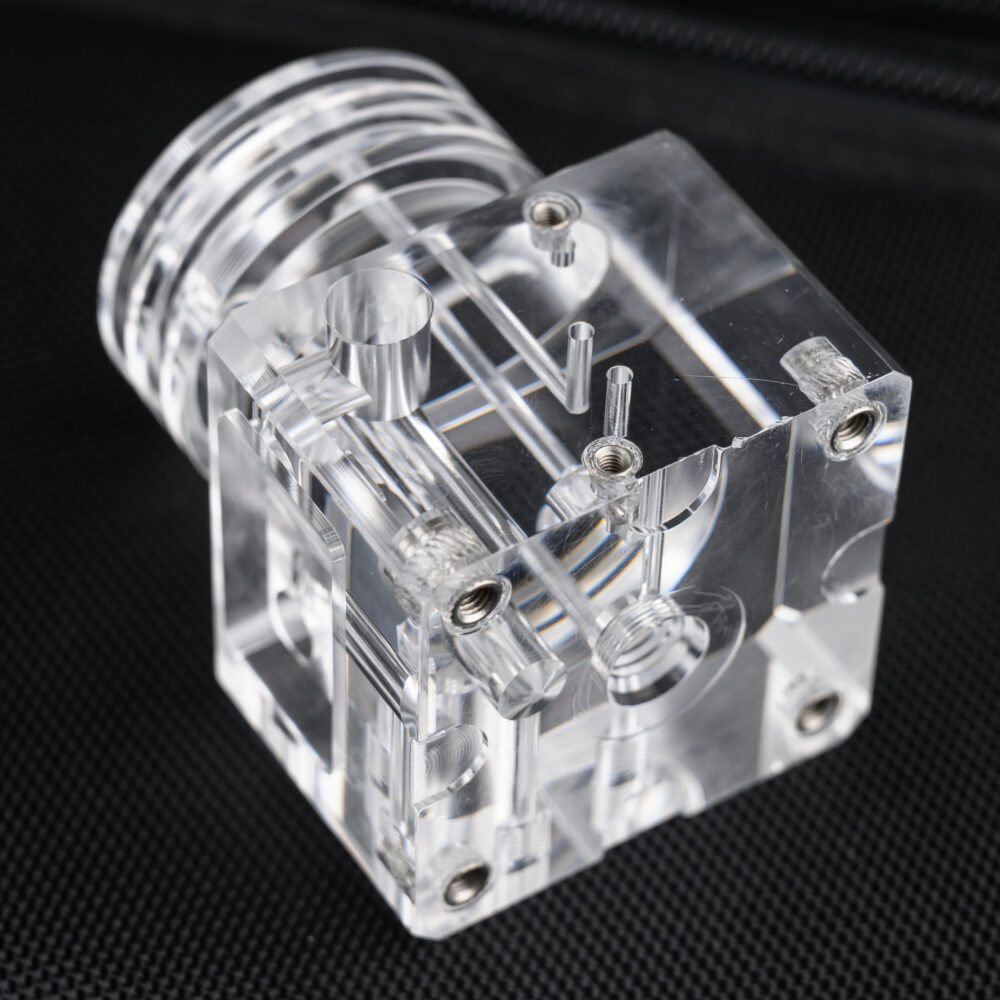

Pexco’s overmolding and insert molding capabilities combine multiple materials into integrated components that eliminate assembly operations, improve performance, and enable designs not achievable through conventional single-material molding. We specialize in molding high-performance thermoplastics around delicate inserts and complex geometries that other molders consider too thin or intricate to process reliably.

Our proprietary tooling designs, robotic material placement systems, and thermal management expertise enable consistent production of overmolded assemblies using challenging materials like PEEK, PFA, FEP, and Torlon—not just commodity elastomers. Whether integrating metal hardware, sensors, or pre-molded substrates, we deliver components with robust bonds between dissimilar materials while maintaining the tight tolerances your application demands.

Insert Molding for Delicate Components

Insert molding places metal or pre-molded plastic components into the mold cavity before injecting polymer around them, creating a single integrated part. This eliminates secondary assembly operations, improves mechanical integrity, and enables designs that combine the properties of multiple materials.

Pexco has developed capabilities significantly more advanced than conventional insert molders:

- Proprietary tool designs and fixturing for inserts commonly considered too thin or complicated to mold

- Robotic material placement ensuring accurate, consistent positioning of complex inserts

- Thermal management systems controlling polymer flow around insert features without displacement or damage

- Dimensional stability maintained through process controls that prevent insert shifting during injection

Metal Insert Capabilities: We regularly mold around brass, steel, and stainless steel inserts. Knurled surfaces and specialized geometries provide mechanical retention, while our process expertise ensures proper polymer encapsulation and bond integrity. Applications include threaded fasteners, electrical contacts, structural reinforcements, and wear-resistant bearing surfaces.

Multi-Material Overmolding

Overmolding adds a second polymer layer onto a pre-molded substrate, combining materials with complementary properties into a single component. Pexco’s multi-shot molding capabilities use multi-barrel injection systems to mold substrate and overmold materials in sequence, creating strong bonds through chemical adhesion or mechanical interlocking.

High-Performance Overmold Combinations

Unlike molders limited to commodity TPE and TPU overmolds, Pexco processes advanced thermoplastics in both substrate and overmold applications:

| Substrate Materials | Overmold Materials |

|---|---|

| Polycarbonate, ABS, Nylon | TPE, TPU, Silicone, Santoprene |

| PEEK, Ultem (PEI), Ryton (PPS) | PEEK, Ultem, fluoropolymers |

| Metal (brass, steel, stainless) | FEP, PFA, fluoropolymers |

This capability enables overmolded components for demanding applications where both materials must withstand high temperatures, aggressive chemicals, or sterilization cycles.

Bonding Considerations

Material selection determines whether bonds form through chemical adhesion or mechanical interlocking. Our engineering team evaluates melting temperatures, coefficients of expansion, and adhesion characteristics to recommend optimal material combinations. For challenging material pairs, we design mechanical interlocking features that ensure reliable long-term performance.

Design Engineering Support

Successful overmolding requires careful attention to material compatibility, gate locations, and insert positioning from the earliest design stages. Pexco’s engineering team provides comprehensive support including:

Material selection guidance

for substrate and overmold combinations optimized for your application requirements

Mold flow analysis

predicting fill patterns, weld line locations, and potential issues before tooling investment

Insert retention design

incorporating knurls, undercuts, or geometric features that ensure mechanical bond integrity

Gate location optimization

minimizing visible witness marks while ensuring complete cavity filling around inserts

Our 6 in-house tool and die centers handle mold design, fabrication, and rapid modifications throughout development. For critical dimensional requirements, our Industrial CT Scanning & Metrology capabilities verify internal features and bond interfaces non-destructively.

See Design Engineering Services for complete engineering support capabilities.

Materials & Resins

Pexco’s overmolding capabilities span the full range of high-performance thermoplastics:

Substrate Materials

Engineering Thermoplastics

Polycarbonate (PC), ABS, Nylon (PA), Acetal (POM)

High-Performance Thermoplastics

PEEK, PEI (Ultem), PPS (Ryton), PSU (Polysulfone)

Metals

Brass, steel, stainless steel inserts

Overmold Materials

Elastomers

TPE, TPU, Silicone, Santoprene

Advanced Thermoplastics

PEEK, PEI (Ultem), EXTEM

Fluoropolymers

FEP, PFA, PVDF, ETFE

Why Choose Pexco?

Proprietary tooling for inserts too thin or delicate for conventional molders

Robotic insert placement for consistent positioning and high-volume production

High-performance overmold materials including PEEK, Ultem, and fluoropolymers

Metal insert molding with brass, steel, and stainless steel

Multi-shot overmolding capabilities for plastic-on-plastic applications

6 in-house tool and die centers for rapid mold development

Industrial CT scanning for non-destructive verification of internal bonds

Tolerances as tight as ±0.0003″ on critical features

ISO 9001:2015 certified, ITAR registered

Full design engineering support from concept through production

Get Started

Contact Pexco’s engineering team to discuss custom tooling requirements for your application.