Our Products

Our Brands

Markets

Capabilities

About Pexco

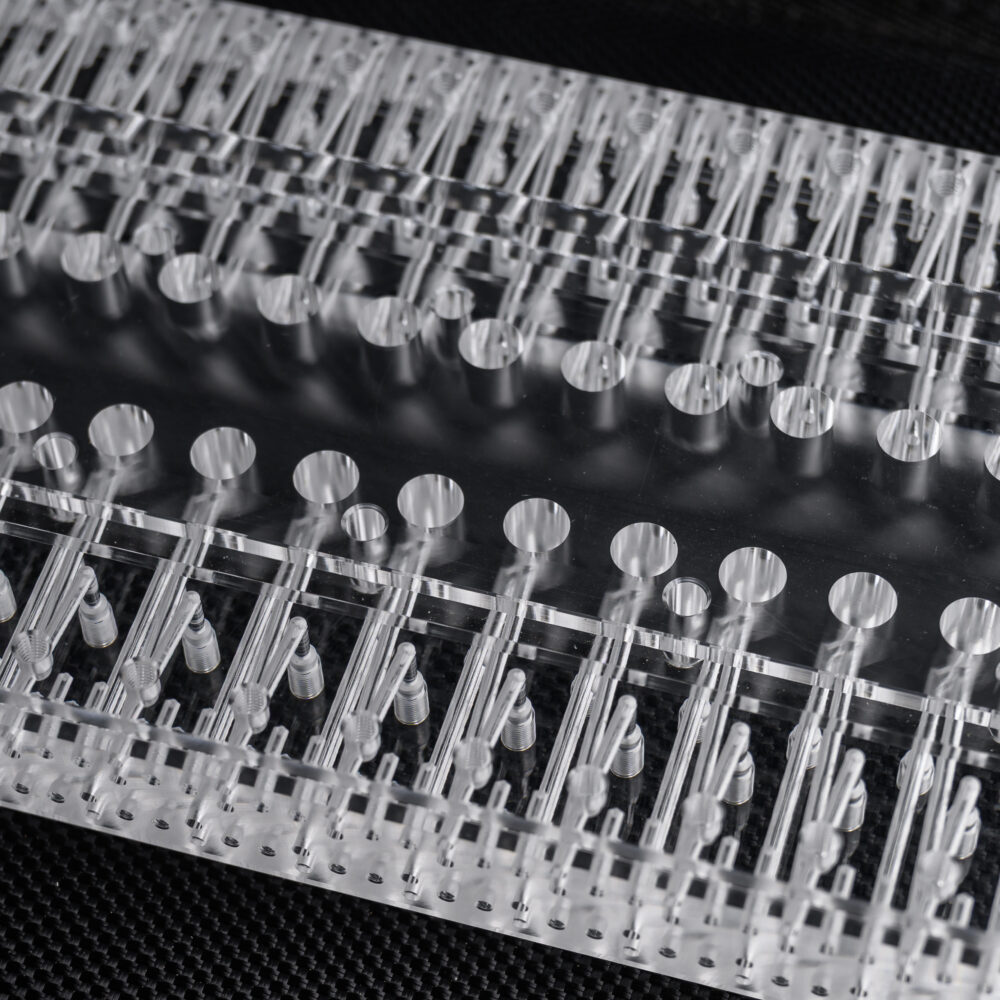

Precision Machining

CNC Milling

Where Ideas Take Shape

Pexco’s CNC milling capabilities produce complex geometries with tight tolerances from high-performance plastic materials, utilizing 3-, 4-, and 5-axis equipment to machine components for aerospace, medical, semiconductor, and industrial applications. Our temperature-controlled machining facilities and advanced CAD/CAM integration enable precision manufacturing of intricate parts from solid stock, castings, or molded components. With expertise machining challenging materials like PEEK, Torlon, PFA, and filled compounds, we deliver exceptional surface finishes and dimensional accuracy across prototype and production volumes.

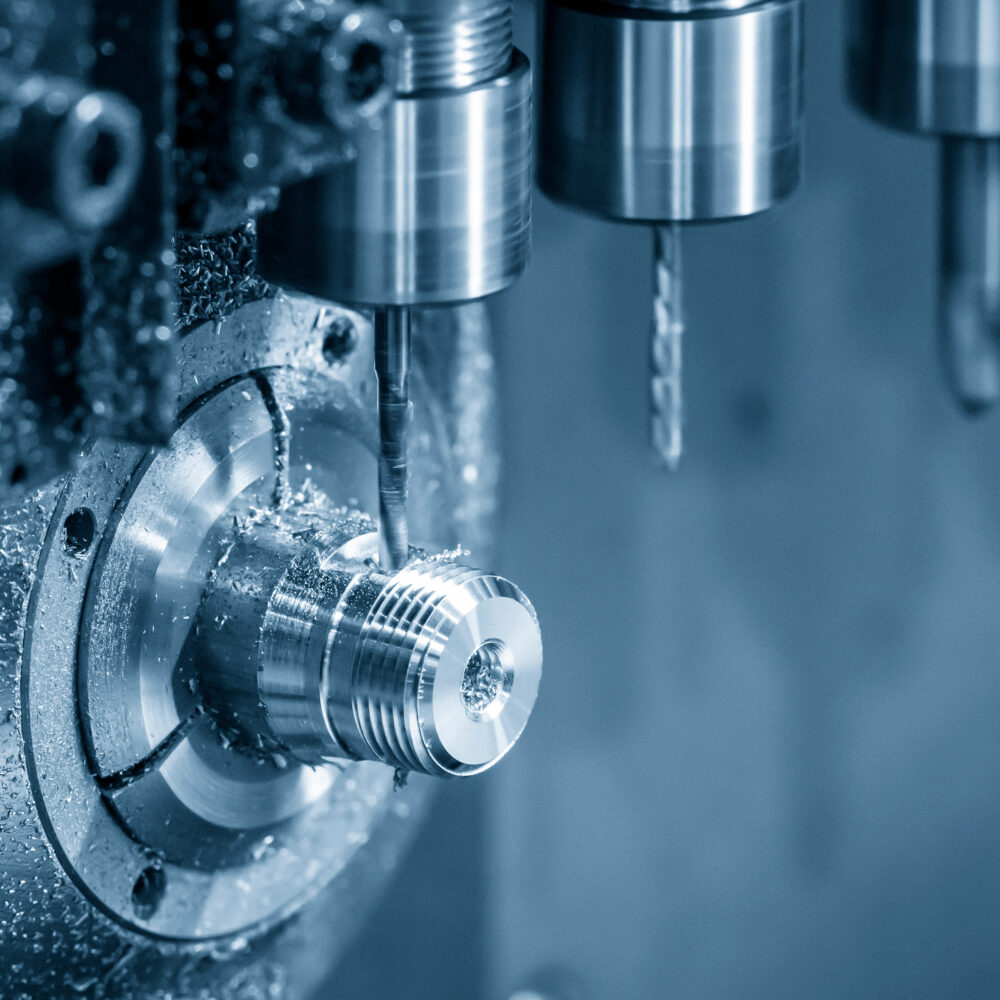

Multi-Axis Capabilities

Our milling capabilities scale to match component complexity:

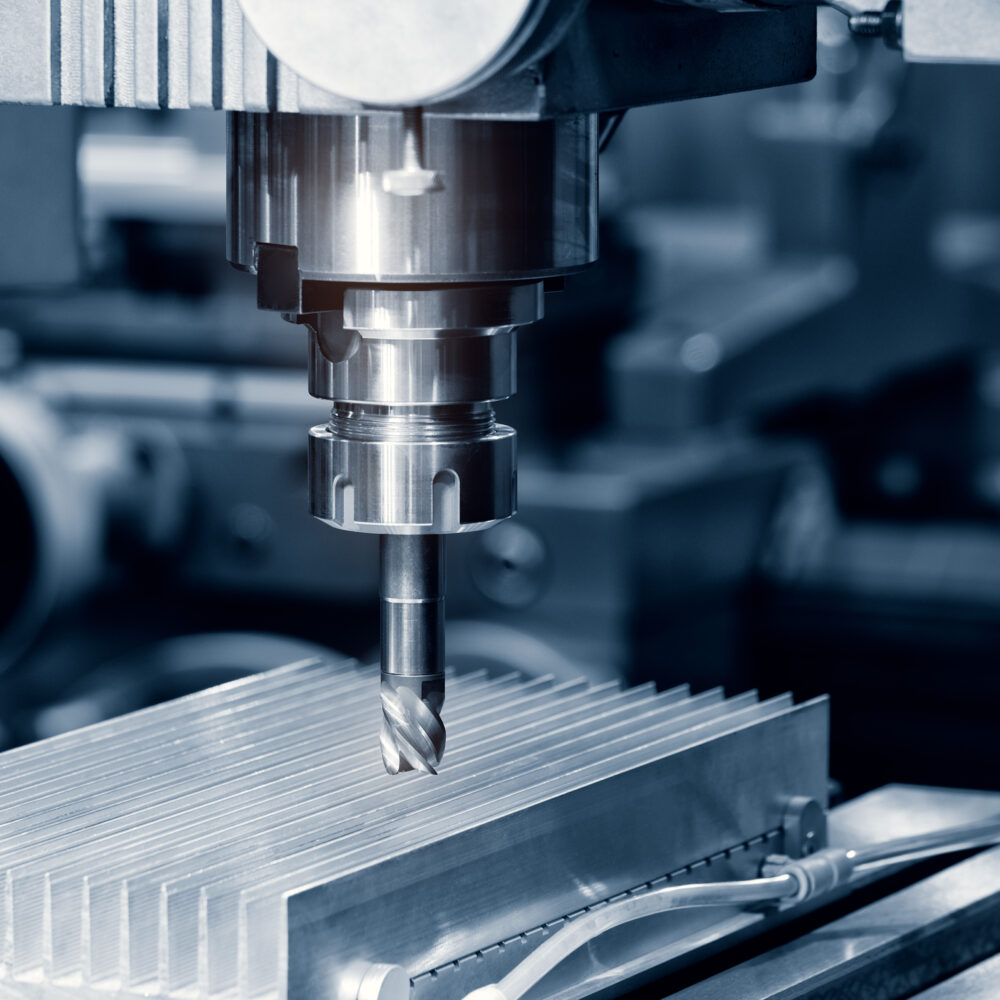

3-Axis Milling

Machines along X, Y, and Z axes to create flat features, pockets, slots, and contoured surfaces. This approach handles prismatic parts efficiently, proving cost-effective for components with features accessible from a single orientation while delivering tight tolerances without complex setups.

4-Axis Milling

Adds rotary indexing around a single axis, enabling features to be machined around cylindrical or curved components without repositioning. Drilling, milling, and contouring operations occur at multiple orientations in one setup, reducing handling time and improving accuracy. Valuable for housings, connectors, and instrumentation parts requiring holes, slots, or mounting features around a central axis.

5-Axis Simultaneous Machining

Our most advanced capability, with the cutting tool moving continuously across five axes to create complex contoured surfaces, undercuts, and compound angles in a single setup. Eliminates multiple repositioning operations, reducing cycle time while improving dimensional accuracy and surface finish consistency. Essential for aerospace components, medical implants, and complex housings requiring intricate geometries impractical with conventional equipment.

Temperature-Controlled Precision

Our temperature-controlled machining environment maintains stable conditions critical when machining thermoplastics that expand and contract with thermal variation. Dimensional accuracy suffers when material temperature fluctuates during machining, particularly with thin-wall components or parts requiring tolerances below ±0.005 inches. Controlled temperature, combined with material-specific feed rates and tooling strategies, prevents thermal expansion issues that compromise dimensional stability.

Vision coordinate measuring machines (CMM) and toolmaker microscopes provide precision measurement and verification throughout the machining process. First-article inspection confirms dimensional accuracy before production runs, while in-process verification ensures consistency across batch quantities.

Material Expertise

Machining high-performance plastics requires specialized knowledge beyond conventional metalworking:

- Imidized Polymers (PEEK, Torlon, PBI): Demand sharp tooling and specific feed rates to prevent heat buildup and material degradation

- Fluoropolymers (PTFE, PFA): Require different strategies due to their tendency to deform under cutting pressure

- Filled Materials: Glass, carbon, or mineral content creates accelerated tool wear and potential delamination if machined improperly

Our expertise extends to selecting appropriate cutting tools, determining optimal speeds and feeds, and implementing cooling strategies that maintain material integrity throughout machining. This knowledge base enables us to machine materials that prove problematic for facilities lacking high-performance plastics experience.

CAD/CAM Integration

Advanced CAD/CAM software integration allows direct import of customer files in native formats, eliminating translation errors and enabling seamless programming. Our digital workflow supports rapid prototype-to-production transitions, with toolpath simulation and verification preventing costly programming errors before metal meets material. This integration proves particularly valuable when iterating designs or scaling from prototype to production volumes

Materials & Resins

Pexco machines high-performance plastics requiring precision milling:

Imidized Polymers

PAI (Torlon), Vespel (Polyimide), PBI – For extreme temperature resistance and mechanical strength

Advanced Fluoropolymers

PTFE, FEP, PFA, PVDF, ETFE – For chemical resistance and low-friction applications

Advanced Thermoplastics

PEEK, PEI (Ultem), PSU (Polysulfone), PPS (Ryton), EXTEM – For structural components requiring high strength and thermal stability

Filled Materials

Glass-filled, carbon-filled, mineral-filled compounds – For enhanced dimensional stability and wear resistance

Commodity Engineering Plastics

Nylon, Acetal, Polycarbonate, Acrylic – For cost-effective precision components

Why Choose Pexco?

3-, 4-, and 5-axis CNC milling capabilities

Temperature-controlled machining environments

Vision CMM and toolmaker microscope measurement

CAD/CAM integration for direct file import

Expertise machining challenging high-performance plastics

Material-specific tooling and cutting strategies

Prototype to production volume capabilities

ISO 9001:2015 and ISO 13485:2016 certified

Expertise machining challenging high-performance plastics

Rapid prototype-to-production transitions

Get Started

Contact Pexco’s precision machining team to discuss your CNC milling requirements and component specifications.