Our Products

Our Brands

Markets

Capabilities

About Pexco

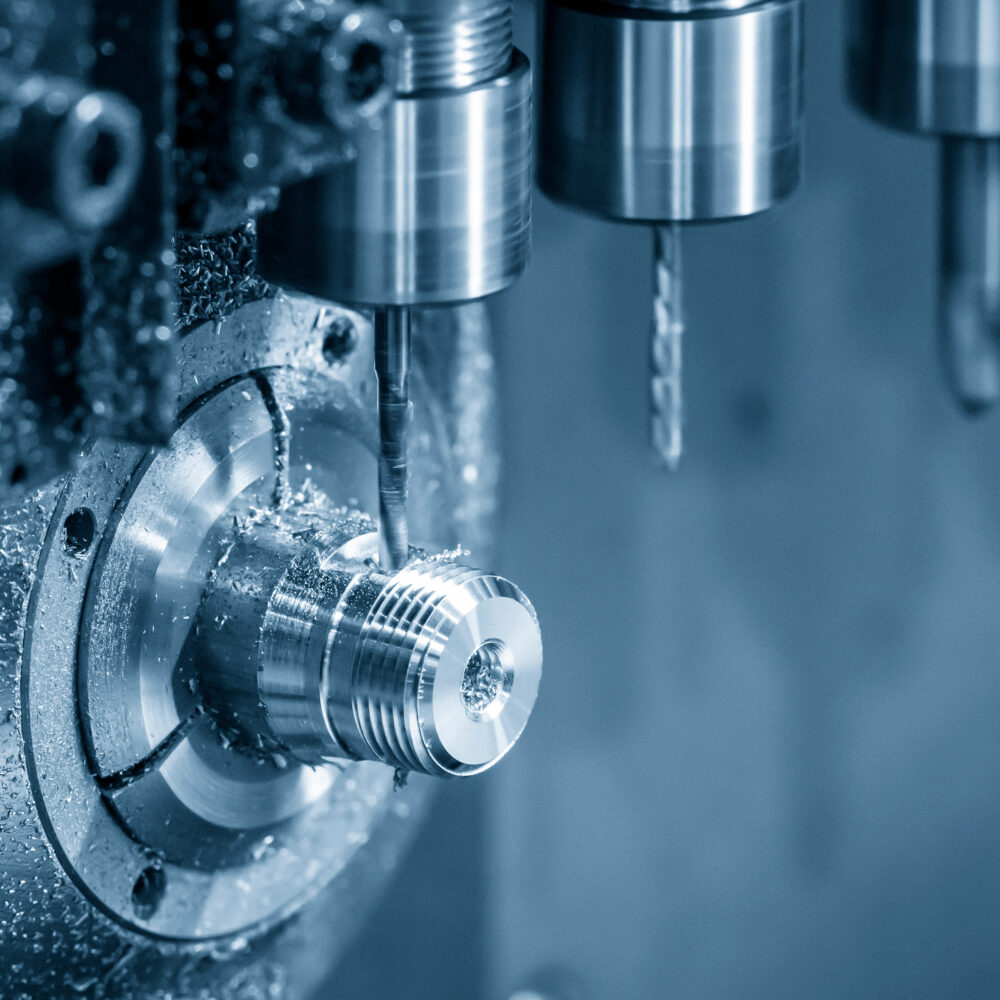

Precision Machining

CNC Turning & Swiss Machining

Where Ideas Take Shape

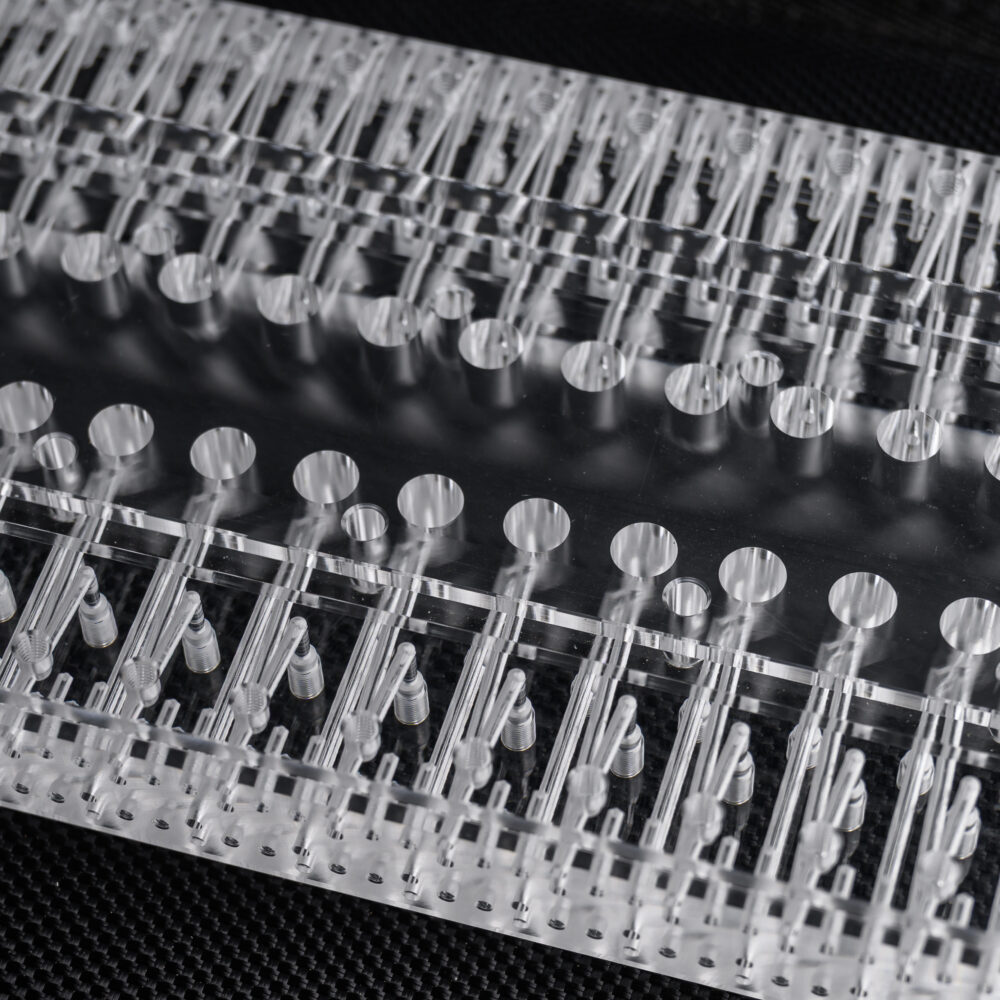

Pexco’s CNC turning and Swiss machining capabilities produce precision cylindrical components from micro-scale parts to large-diameter components up to 20 inches. With over 40 CNC turning and Swiss machining centers, we manufacture complex rotational geometries incorporating turned features, cross-holes, slots, and threaded connections in high-performance plastics for medical device, aerospace, semiconductor, and industrial applications. Our multi-axis mill-turn equipment with sub-spindles and live tooling enables complete part production in a single setup, eliminating secondary operations while maintaining exceptional dimensional accuracy and surface finish quality.

Multi-Axis Mill-Turn Capabilities

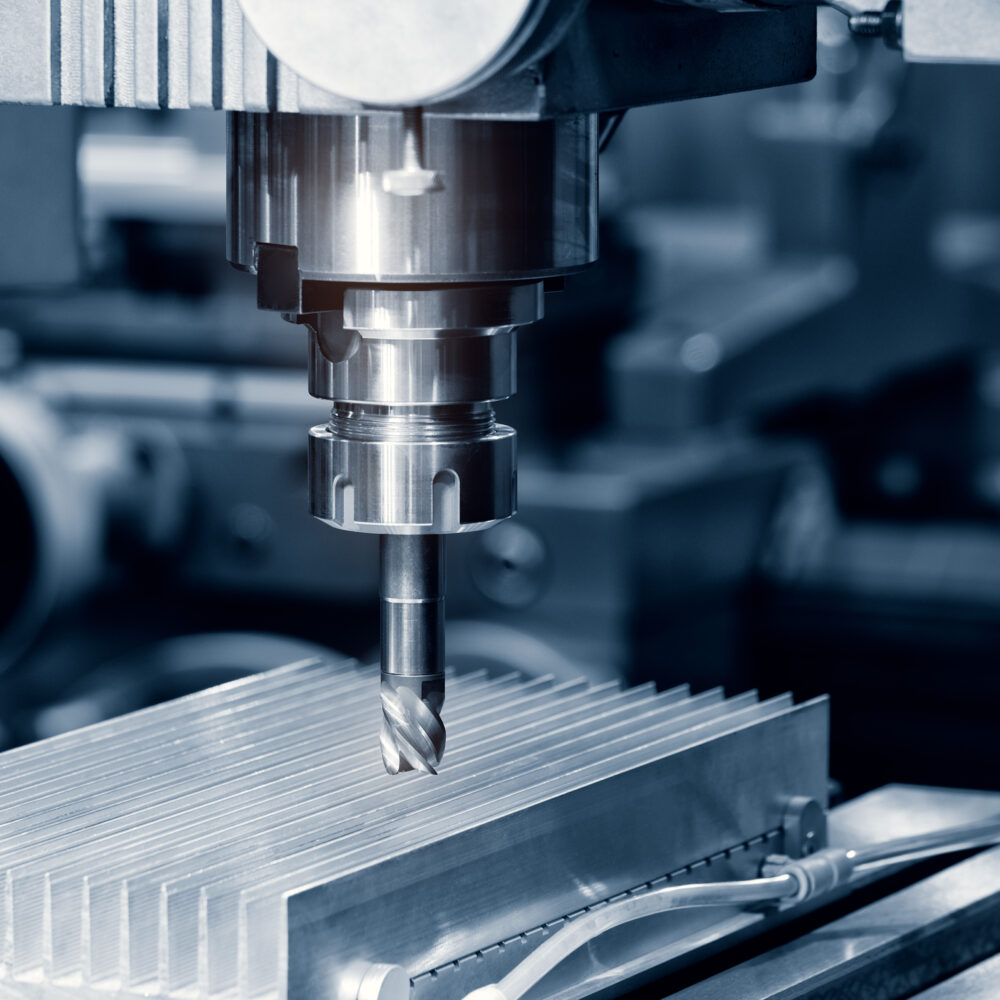

Conventional CNC turning machines components from bar stock, castings, or molded blanks, rotating the workpiece while stationary cutting tools create cylindrical features, tapers, threads, and contours. Our multi-axis mill-turn equipment extends these capabilities significantly:

Live Tooling

Powered cutting tools rotate independently of the workpiece spindle, enabling milling operations like cross-holes, flats, keyways, and pockets without transferring parts to separate machines.

Sub-Spindle Functionality

The main spindle transfers partially completed parts to a secondary spindle, enabling backside operations and complete part production without manual intervention. Essential for complex components requiring features on both ends, threaded connections, or precise relationships between front and rear features.

Single-Setup Manufacturing

Eliminates repositioning errors that compromise dimensional accuracy when parts move between machines. Particularly valuable for components requiring multiple operations while maintaining tight tolerances.

Swiss Machining for Precision Components

Swiss-type CNC machines excel at producing small-diameter precision components with exceptional accuracy and surface finish through a fundamentally different approach than conventional turning. The Swiss turning process feeds bar stock through a guide bushing that supports the workpiece immediately adjacent to the cutting zone, minimizing deflection and enabling tight tolerances on slender parts that would bend or chatter in conventional turning operations.

Swiss Machining Advantages

- Guide bushing support enables high L/D ratio parts impractical with conventional turning

- Maintains tight tolerances on small-diameter, slender components

- Combines turning, drilling, threading, milling in single automatic cycle

- Unattended operation with automatic bar feeding for production efficiency

Medical device components, connectors, instrumentation parts, and precision fittings benefit from Swiss machining’s ability to maintain tolerances across small-diameter features while incorporating multiple operations. Our Swiss machining capabilities handle both prototype development and production quantities.

Material Considerations for Turning

High-performance plastics present unique challenges in turning operations. Cutting tool selection, feed rates, and speeds must account for each material’s thermal characteristics, tendency to deform under cutting pressure, and chip formation behavior.

Material-Specific Challenges

- PEEK, Torlon, Imidized Polymers: Machine relatively well but generate heat affecting dimensional accuracy if not properly managed

- Fluoropolymers (PTFE, FEP): Require extremely sharp tools and specific cutting parameters to prevent material smearing or dimensional distortion

- Filled Materials: Glass, carbon, or mineral additives create accelerated tool wear and require different tooling strategies than unfilled resins

Temperature-controlled machining environments maintain material stability during turning, particularly important with thermoplastics prone to thermal expansion. Dimensional verification using coordinate measuring equipment ensures components meet specification across critical features.

Materials & Resins

Pexco machines high-performance plastics for turning and Swiss machining applications:

Imidized Polymers

PAI (Torlon), Vespel (Polyimide), PBI – For extreme temperature and wear resistance in precision turned components

Advanced Fluoropolymers

PTFE, FEP, PFA, PVDF, ETFE – For chemical resistance and low-friction applications requiring precision cylindrical features

Advanced Thermoplastics

PEEK, PEI (Ultem), PSU (Polysulfone), PPS (Ryton), EXTEM – For structural components requiring high strength and dimensional stability

Filled Materials

Glass-filled, carbon-filled, mineral-filled compounds – For enhanced mechanical properties and dimensional stability

Commodity Engineering Plastics

Nylon, Acetal, Polycarbonate, Acrylic – For cost-effective precision turned components

Why Choose Pexco?

40+ CNC turning and Swiss machining centers

Turning capacity from micro-scale to 20-inch diameter

Multi-axis mill-turns with live tooling and sub-spindles

Swiss machining for high length-to-diameter ratio parts

Single-setup complete part manufacturing

Temperature-controlled machining environments

Coordinate measuring equipment for dimensional verification

Expertise machining challenging high-performance plastics

Prototype to production volume capabilities

ISO 9001:2015 and ISO 13485:2016 certified

Complement to molding and milling capabilities

Get Started

Contact Pexco’s precision machining team to discuss your turning and Swiss machining requirements.