Our Products

Our Brands

Markets

Capabilities

About Pexco

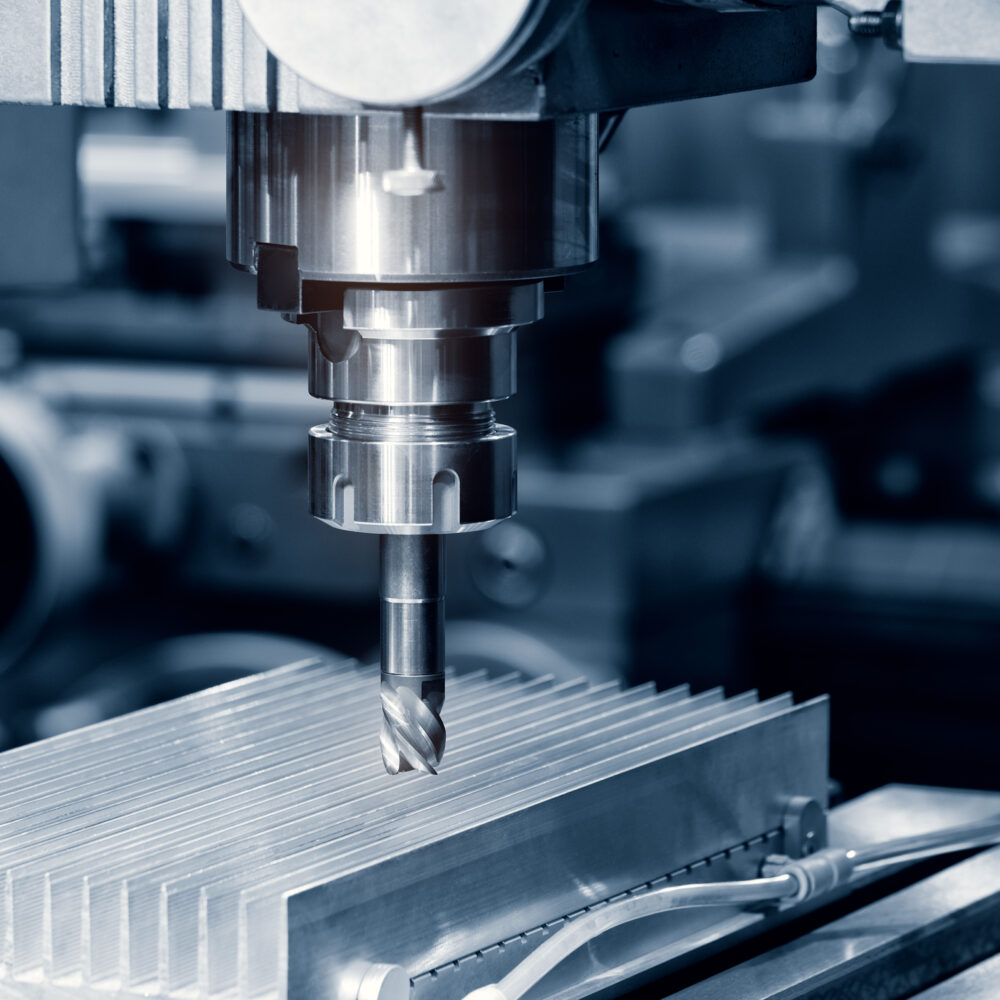

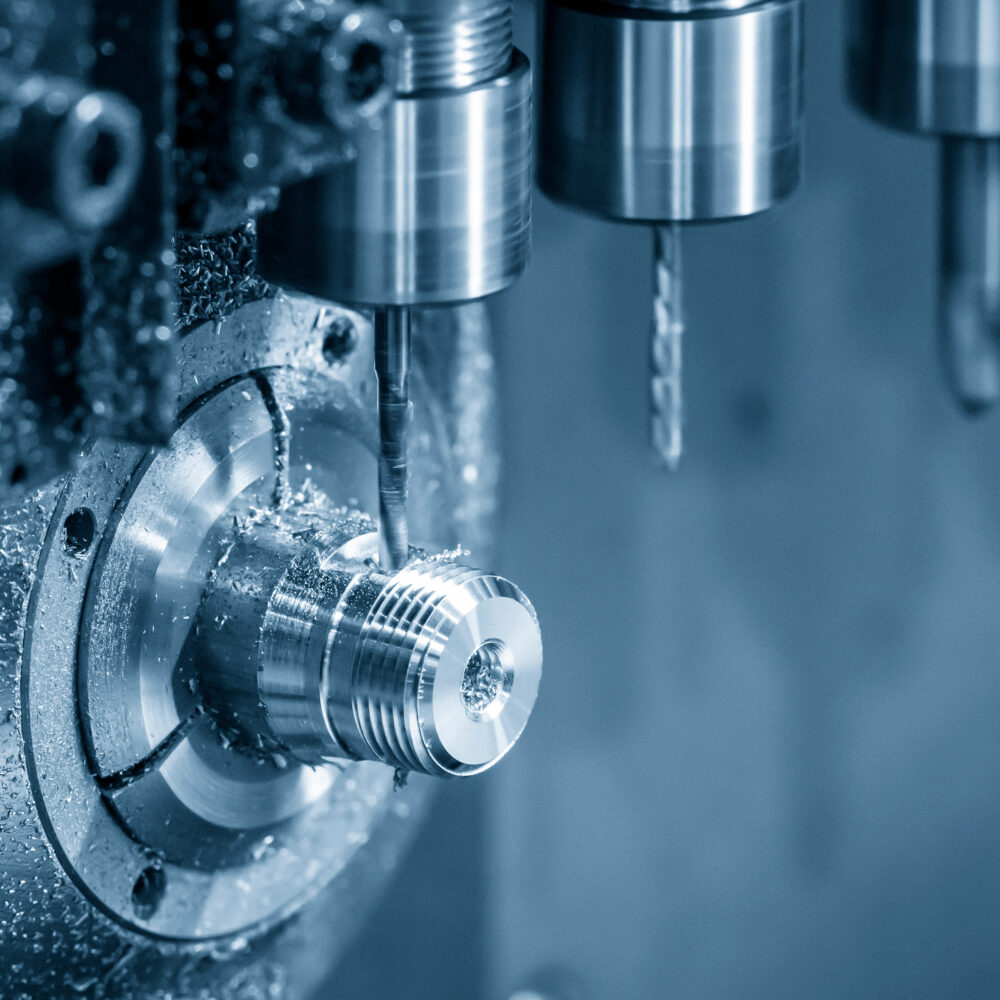

Precision Machining

Surface Finishing & Treatment

Where Ideas Take Shape

Pexco’s surface finishing and heat treatment capabilities optimize performance and appearance of precision-machined plastic components through specialized processes including vapor polishing, annealing, stress relieving, and mechanical finishing techniques. These post-machining treatments prove essential for components requiring optical clarity, dimensional stability, enhanced surface properties, or specific aesthetic qualities. Our expertise spans materials from commodity thermoplastics to high-performance fluoropolymers and imidized polymers, delivering finished components ready for demanding applications in medical devices, optical systems, aerospace assemblies, and precision instrumentation.

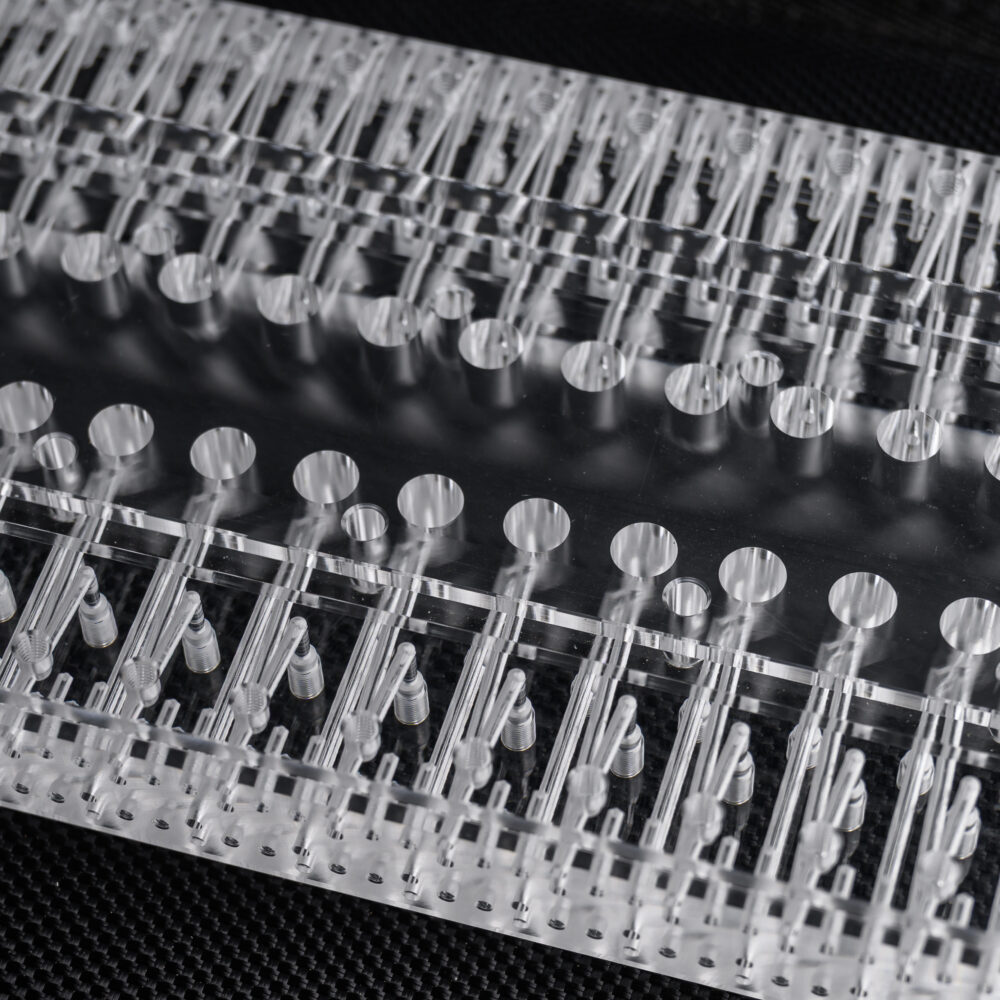

Vapor Polishing

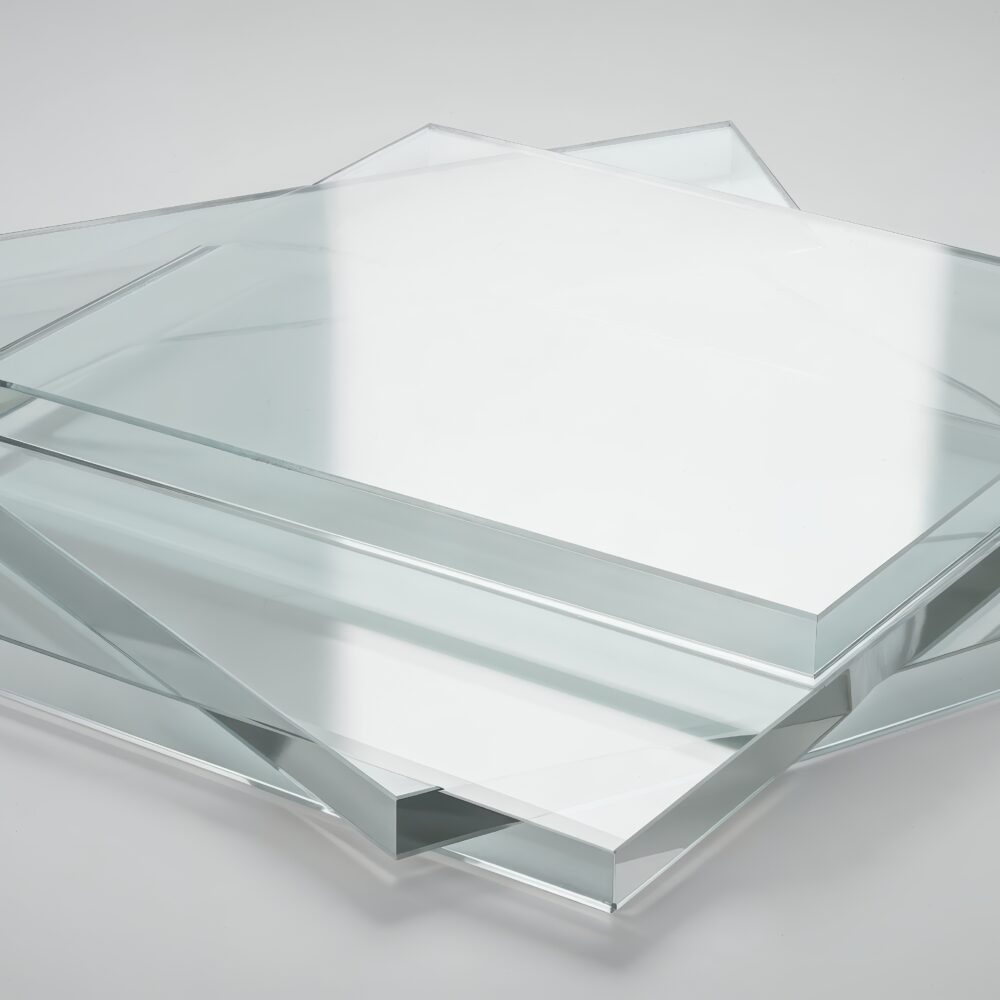

Vapor polishing creates optically clear, defect-free surfaces on transparent and translucent plastics by briefly exposing machined parts to solvent vapor that smooths surface irregularities at the molecular level. The controlled vapor environment softens the outermost material layer just enough to allow surface tension to eliminate machining marks, tool chatter, and microscopic scratches without affecting dimensional accuracy.

Key Advantages

- Transforms cloudy, machined surfaces into glass-like clarity comparable to molded optical components

- Preserves tight tolerances—unlike mechanical polishing, no material removal or dimensional changes occur

- Works on complex geometries including internal bores, threaded features, and intricate contours difficult to mechanically polish

Ideal Applications: Viewports, lenses, light guides, flow visualization windows, medical device housings requiring visual access, and any transparent component where optical clarity proves essential.

Annealing and Stress Relieving

Machining, molding, and forming operations introduce internal stresses that can cause dimensional instability, cracking, or warpage over time or when exposed to elevated temperatures. Annealing and stress-relieving heat treatments remove these stresses through controlled thermal processing.

The Process: Components heat to specific temperatures below the material’s glass transition or melting point, holding for calculated durations that allow molecular relaxation and stress redistribution. Gradual cooling prevents introduction of new stresses, leaving components in a stable, relaxed state.

Why It Matters

- Prevents dimensional changes during service or thermal exposure

- Eliminates stress cracking in precision components

- Reduces warpage in thin-wall or complex geometries

- Optimizes long-term dimensional consistency

Ideal Candidates for Stress Relieving

- Precision components operating in demanding thermal environments

- Parts with tight tolerances requiring long-term dimensional stability

- Thin-wall or complex geometries more susceptible to warpage

- High-performance materials like PEEK, PEI, and imidized polymers

- Parts machined from thick stock where material removal creates significant stress redistribution

Flame Polishing

Flame polishing applies brief, controlled flame exposure to plastic surfaces, melting the outermost layer to create smooth, glossy finishes on edges and flat surfaces. This technique proves effective for acrylic, polycarbonate, and other thermoplastics where a high-gloss appearance is desired without optical clarity requirements. The process works well on edges, chamfers, and accessible surfaces but cannot reach internal features or complex geometries.

Flame polishing requires careful control to prevent overheating that would cause bubbling, discoloration, or dimensional distortion. Our experience with material-specific flame polishing parameters ensures consistent results without compromising dimensional accuracy on adjacent precision features.

Mechanical Finishing

Mechanical finishing encompasses buffing, tumbling, and media blasting processes that modify surface texture and appearance through controlled abrasion.

Buffing

Progressive polishing compounds create high-gloss surfaces, though not achieving the optical clarity of vapor polishing.

Tumbling

Ceramic media or organic compounds create uniform matte finishes while deburring edges and removing sharp corners.

Media Blasting

Glass beads, plastic media, or aluminum oxide create uniform matte textures, prepare surfaces for bonding or coating, or produce decorative finishes. Valuable for consistent surface appearances across complex geometries, though dimensional changes must be considered when working with tight tolerances.

Surface Texturing

Surface texturing creates controlled roughness patterns that improve grip, reduce friction, manage light reflection, or prepare surfaces for adhesive bonding. Chemical etching, mechanical texturing, and laser ablation can produce specific surface characteristics matched to functional requirements. Textured surfaces prove valuable for medical device components requiring secure handling, optical components managing light diffusion, or assemblies requiring enhanced bonding surfaces.

Materials & Resins

Pexco provides surface finishing and heat treatment for precision-machined plastics:

Optical Clarity Materials

Acrylic, Polycarbonate, transparent PEEK – For vapor polishing to achieve glass-like clarity

High-Performance Thermoplastics

PEEK, PEI (Ultem), PSU (Polysulfone), PPS (Ryton) – For stress relieving and dimensional stabilization

Imidized Polymers

PAI (Torlon), PBI – For annealing and stress relief in extreme service conditions

Fluoropolymers

PTFE, FEP, PFA, PVDF, ETFE – For specialized finishing preserving chemical resistance

Filled Materials

Glass-filled, carbon-filled compounds – For stress relief addressing machining-induced stresses

Why Choose Pexco?

Vapor polishing for optical clarity without dimensional change

Annealing and stress-relieving heat treatment capabilities

Flame polishing for glossy edge finishes

Mechanical buffing and tumbling

Media blasting for uniform matte finishes

Surface texturing for functional requirements

Expertise across commodity to high-performance materials

Temperature-controlled processing environments

Dimensional verification before and after finishing

ISO 9001:2015 and ISO 13485:2016 certified

Integrated with machining operations for complete solutions

Get Started

Contact Pexco’s precision machining team to discuss surface finishing and heat treatment requirements for your components.