Our Products

Our Brands

Markets

Capabilities

About Pexco

Pexco Capabilities

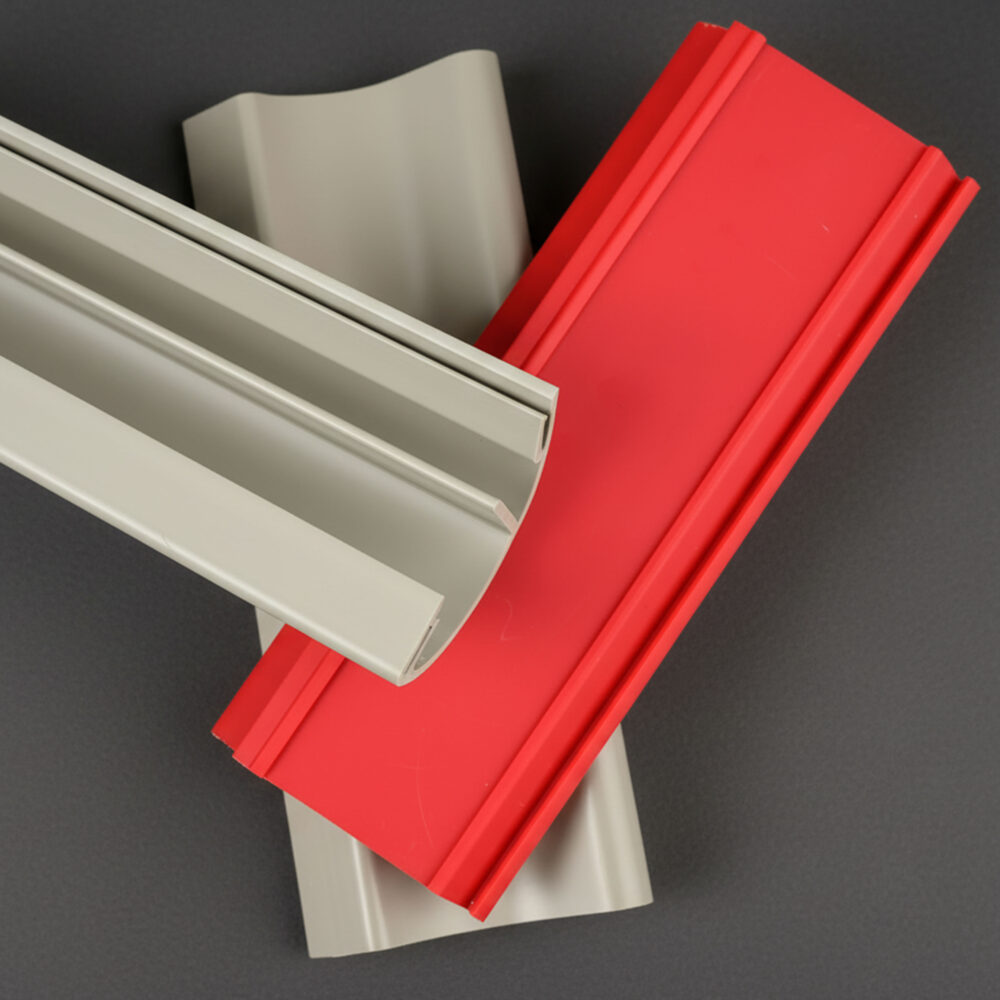

Standard Shape and Size Extrusions

Pexco maintains extensive inventory of standard plastic shapes for immediate shipment—tubing, pipe, rod, sheet, film, and heat shrink products ready to ship same-day in most cases. Our stock shapes serve as machining stock for fabricators, drop-in components for OEMs, and starting material for prototyping and production.

When standard dimensions don’t fit your requirements, our manufacturing capabilities support custom sizes across all product categories.

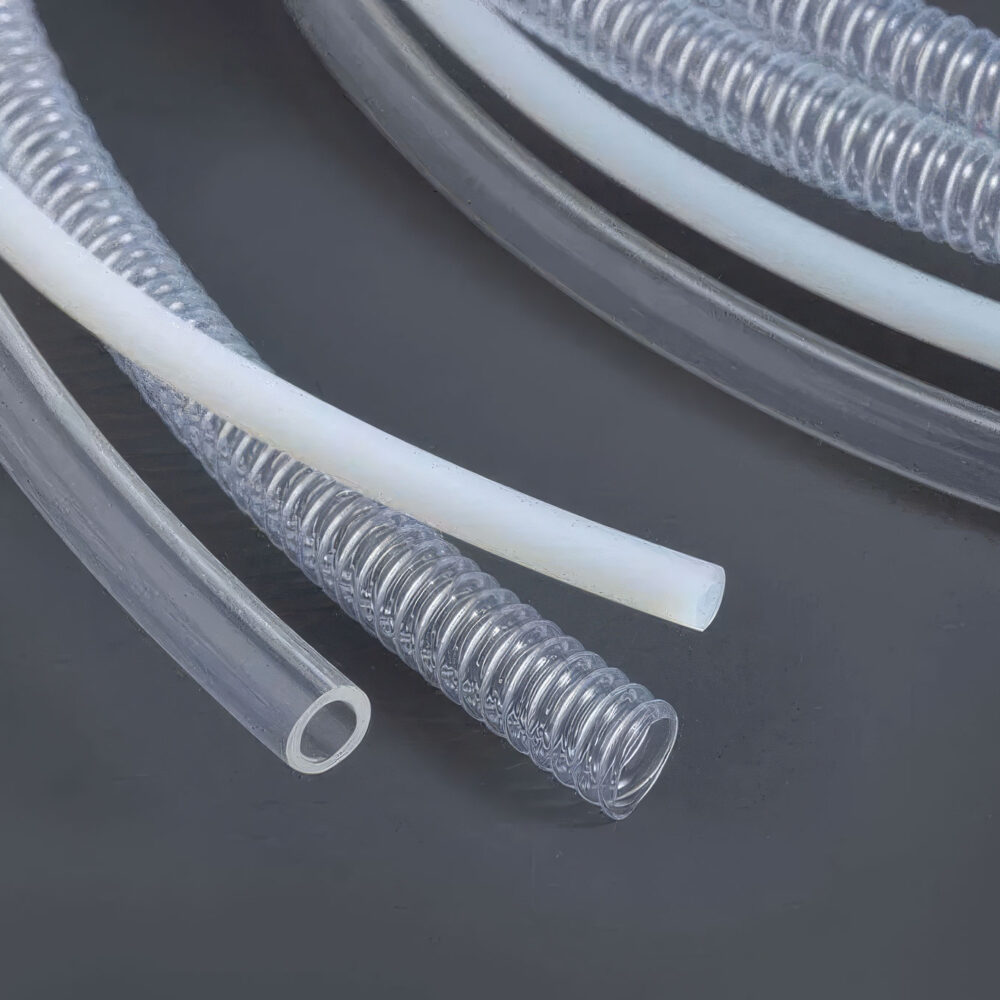

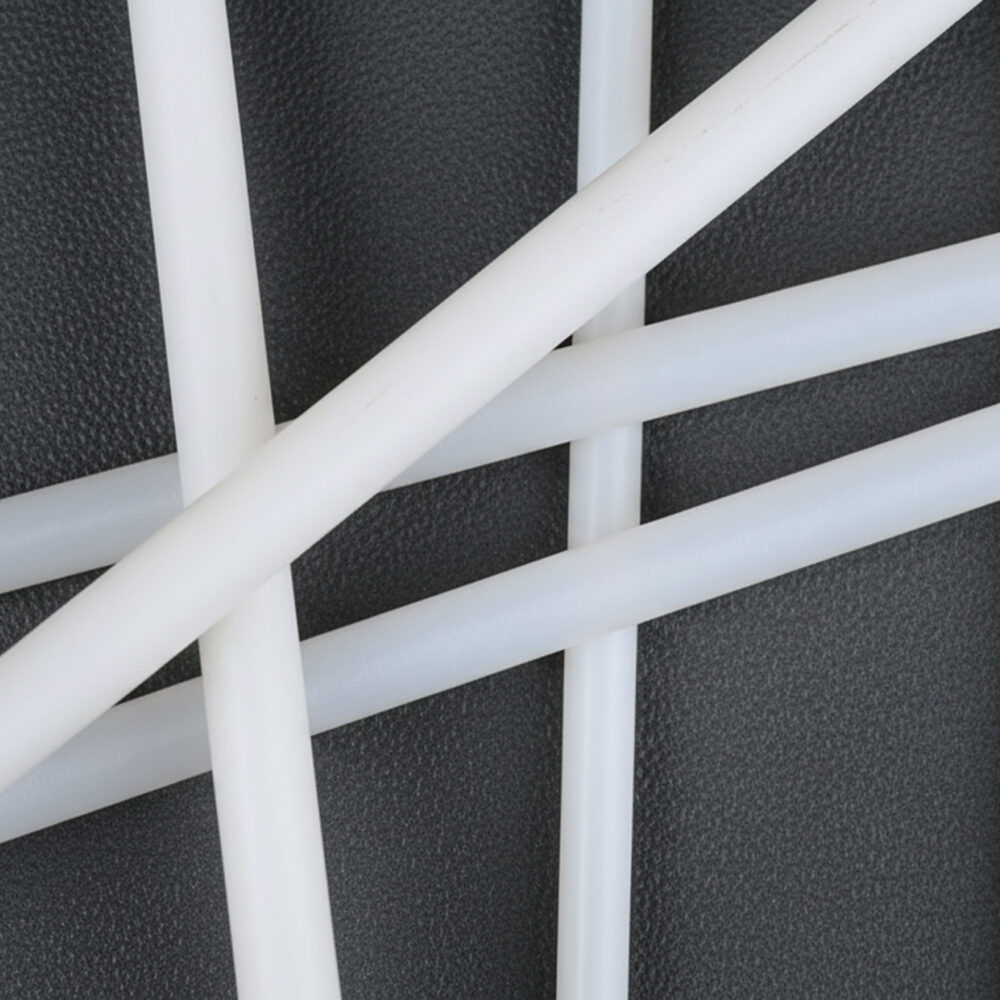

Tubing

Thermoplastic and fluoropolymer tubing in diameters from 1/32″ ID to 4-1/2″ OD. Available materials span commodity thermoplastics through high-performance fluoropolymers.

Thermoplastic Tubing

Nylon (PA6, PA11, PA12), Polyurethane, Polyethylene (HDPE, LDPE), Polypropylene, PVC, Polycarbonate, Polystyrene (HIPS), Polysulfone, and ABS. Stock inventory includes standard sizes in multiple colors with custom colors and printing available.

Fluoropolymer Tubing

PTFE, FEP, PFA, UHP PFA, PVDF, PVDF Flex, ECTFE, ETFE, PCTFE, and THV. Available in standard sizes with same-day shipping from stock.

Applications include pneumatic systems, fluid transfer, medical devices, chemical processing, food and beverage, and semiconductor manufacturing.

Pipe

Larger-diameter fluoropolymer pipe for chemical processing, semiconductor wet bench, and industrial fluid handling systems. Available in FEP, PFA, UHP PFA, PVDF, and PVDF Flex with standard pipe schedules.

Altaflo® branded pipe products meet ASTM D6867-03, ASTM D3307, FDA 21 CFR 177.1550, USP Class VI, and NSF 61/372 certifications where applicable.

High-purity applications benefit from our ALTAPAK™ option—surfactant cleaning, DI rinse, and nitrogen purge performed in a Class 100 cleanroom environment.

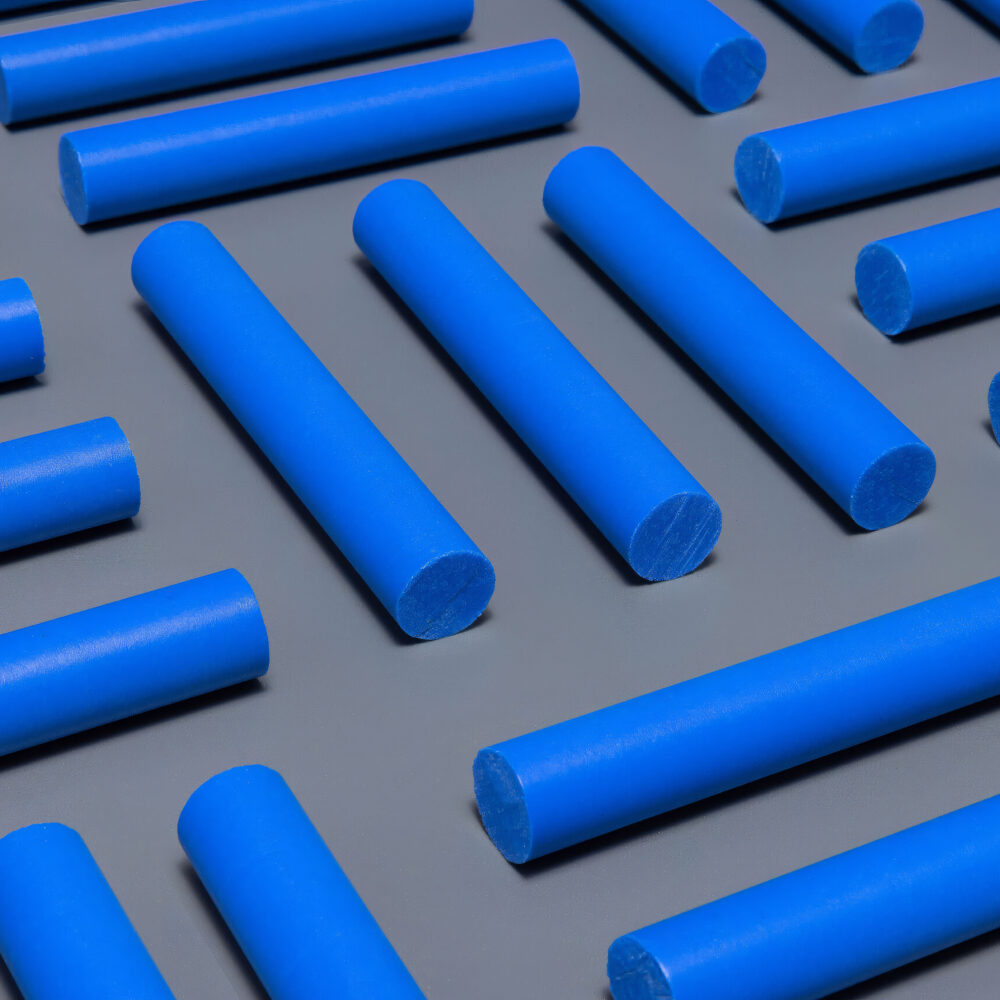

Rod

Extruded and compression molded rods serve as machining stock for seals, bearings, valve components, electrical insulators, and precision mechanical parts.

Extruded PTFE Rod

Diameters from 0.125″ to 5″ in standard 6′ and 12′ lengths. Available in virgin, modified, reprocessed, and Enflon® filled compounds.

Molded PTFE Rod

Larger diameters for heavy-duty machining applications. Virgin, Super Modified, and Enflon® filled options.

Thermoplastic Rod

Nylon, Polycarbonate, HDPE, Polypropylene, and other engineering resins.

Enflon® filled compounds add glass, carbon, bronze, graphite, or custom filler blends to enhance wear resistance, reduce creep, or modify friction characteristics.

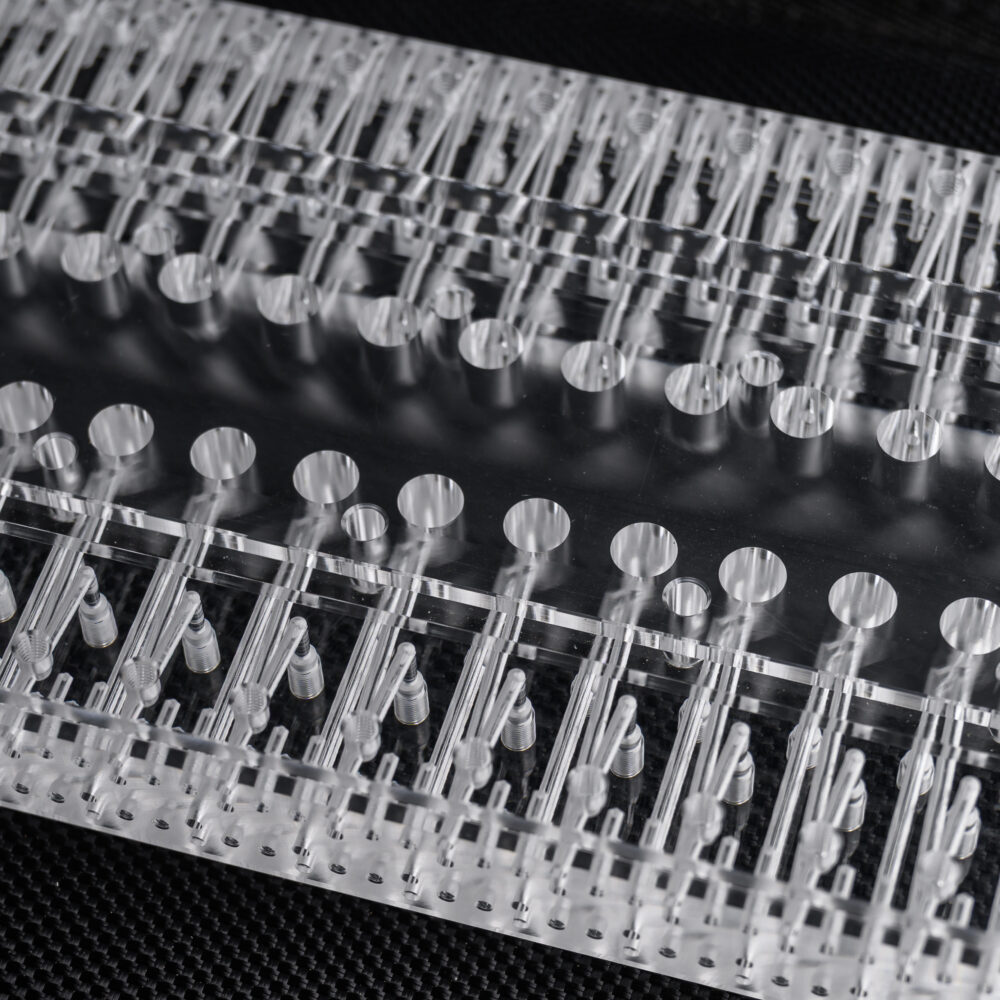

Sheet

Compression molded PTFE sheet for gaskets, bearings, slide plates, electrical insulation, and machining stock.

Standard Sizes

Thicknesses from 0.187″ to 5″, sheets up to 48″ × 48″. Cut-to-size available.

Material Options

Virgin PTFE, Modified PTFE, and Enflon® filled compounds. Sheets can be supplied etched (one or two sides) or with pressure-sensitive acrylic adhesive backing.

Specialty Options

Dimpled sheets for bridge bearing applications requiring enhanced lubrication and wear resistance.

Pexco is specified as the supplier of PTFE skived sheets under Boeing specification BMS8-121 and Bombardier/Airbus specification BAMS533-001.

Film

Skived PTFE film in roll form or cut-to-size sheets. Widths up to 72″ and thicknesses from 0.0015″ to 0.250″.

Material Options

Virgin PTFE, Modified PTFE, Reprocessed PTFE, and Enflon® filled compounds.

Applications

Gasket material, electrical insulation, release films, bearing surfaces, and lamination substrates.

Film products provide a low-friction, non-stick surface suitable for high-temperature and high-dielectric applications.

Heat Shrink

Heat-shrinkable tubing for wire and cable insulation, strain relief, environmental sealing, and component protection. Manufacturing heat shrink products since 1964.

Polyolefin Heat Shrink

2:1, 2.5:1, and 3:1 shrink ratios. Single-wall and multi-wall (adhesive-lined) constructions.

Specialty Materials

Fluoropolymer heat shrink (PTFE, FEP), PVC, silicone, and other specialty compounds for demanding temperature, chemical, or regulatory requirements.

Shrink ratios from 1.67:1 through 4:1 accommodate irregular shapes, oversized components, and inline connections.

Get Started

Contact Pexco’s engineering team to discuss your technical requirements, material selection, or tooling challenges.