Our Products

Our Brands

Markets

Capabilities

About Pexco

Pexco Capabilities

Value-Added Services

Pexco delivers finished, ready-to-use components—not just raw extrusions. Our value-added services integrate fabrication, assembly, and packaging operations into a single-source solution, reducing your supplier count and streamlining time to market.

In-Line Processing

Many secondary operations can be executed during extrusion rather than as separate downstream steps. In-line processing reduces handling, improves consistency, and lowers per-part costs for high-volume production.

Tape Application

In-line taping systems apply single or multiple adhesive laydowns with tight tolerance positioning. Double-sided tapes, foam tapes, and pressure-sensitive adhesives can be applied as profiles exit the extrusion line.

Punching & Notching

On-the-fly punching adds holes, notches, windows, and contoured cutouts without secondary handling. Punch dies are designed and built in-house to match your specifications.

Product Marking

Inline printing and marking systems apply part numbers, lot codes, barcodes, or branding directly during production.

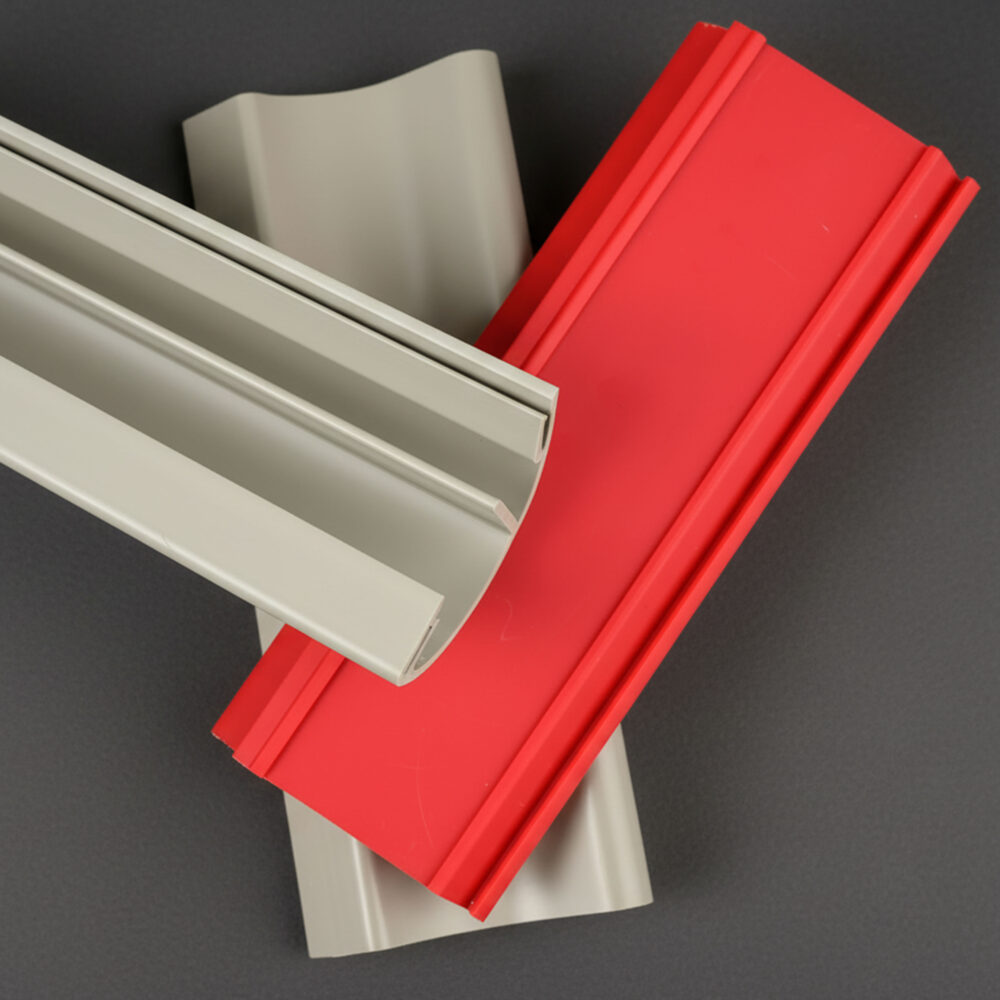

Secondary Fabrication

Operations that cannot be performed in-line are handled by dedicated fabrication cells running multiple shifts. Our fabrication capabilities include:

- Cutting – Precision cut-to-length, mitering, and slitting using high-speed CNC routers, dual-head miter saws, and radial arm saws with programmable positioning

- Routing – CNC routing for complex cutouts, pockets, and edge profiles

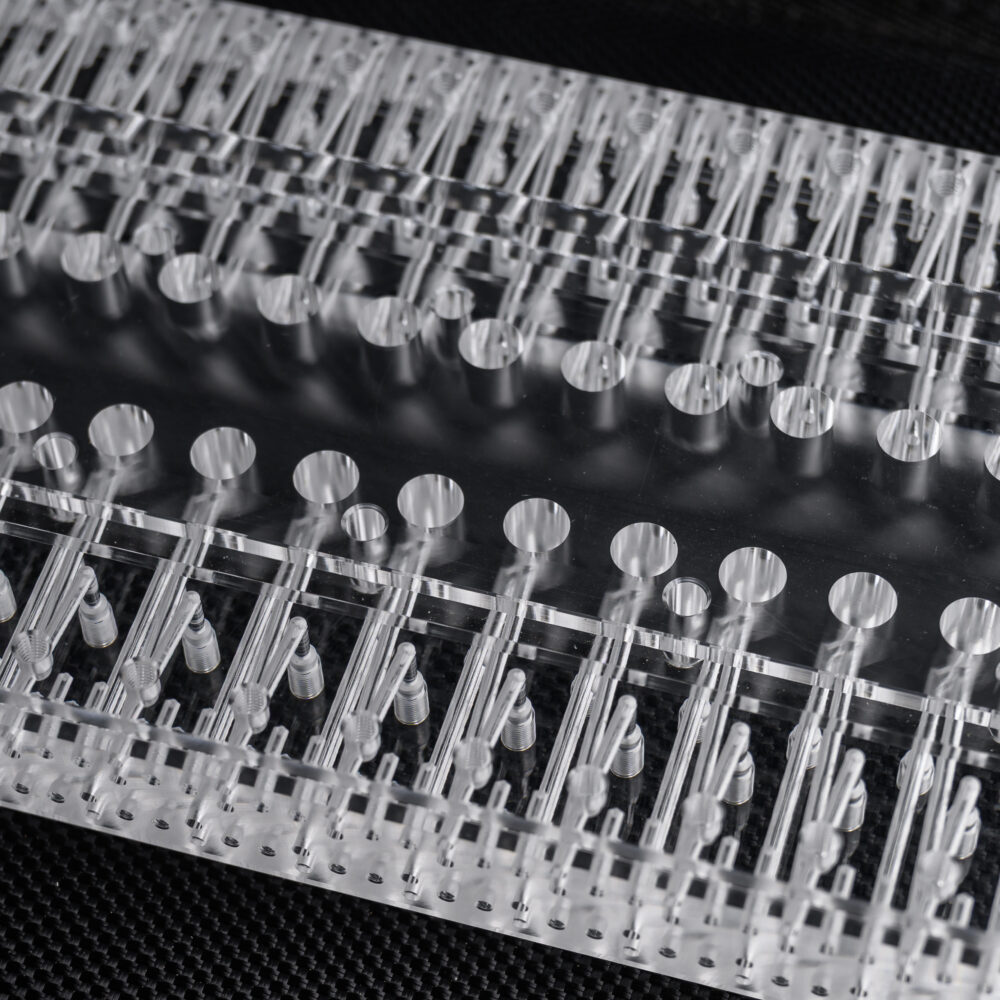

- Drilling & Tapping – Hole patterns, threaded inserts, and precision-located features

- Punching – Quick-change punching systems for holes, slots, and custom shapes

- Splicing – Hot and cold bonded splicing for continuous lengths or closed-loop assemblies

- Heat Sealing – End closures and sealed joints for tubing and profile applications

- Surface treatments – Spattercoating, hot stamping, embossing, slip coating, and flocking for friction modification or aesthetic enhancement

Fixtures and tooling are designed and built in-house, enabling rapid setup for new part configurations and consistent repeatability across production runs.

Assembly & Kitting

Pexco integrates multiple components into finished assemblies or kitted packages, reducing your downstream labor and consolidating your supply chain.

Component Assembly

We assemble extruded profiles with hardware, gaskets, fasteners, inserts, or mating components to deliver installation-ready products. Assembly operations include mechanical fastening, adhesive bonding, and snap-fit integration.

Custom Kitting

Multiple parts and components packaged together for point-of-use convenience. Kitting reduces your inventory management burden and ensures your production line or field crews receive complete, counted sets rather than bulk components.

Sub-Assemblies

Partially assembled units ready for final integration into your larger products or systems.

Packaging & Labeling

Final packaging protects your components through distribution and presents them ready for your production floor, retail shelf, or end customer.

- Custom packaging configurations matched to your handling and storage requirements

- Private label packaging for distribution or retail applications

- Barcoding and labeling for inventory tracking and traceability

- Bulk, individual, or kit packaging options

Why Choose Pexco for Value-Added Services?

Single-source solution

Extrusion, fabrication, assembly, and packaging from one supplier reduces coordination overhead and lead times

In-house tooling

Custom fixtures, dies, and quick-change systems designed and built by our engineering team

Scalable capacity

Multi-shift fabrication cells handle prototype quantities through high-volume production

Quality integration

Fabrication and assembly operations fall under the same ISO 9001:2015 quality systems as our primary manufacturing

Get Started

Contact Pexco’s engineering team to discuss your technical requirements, material selection, or tooling challenges.