Custom is What We Do Best

See What Else Pexco Can Mold For You

When you think of Pexco, chances are you think of precision — precision in engineering, in manufacturing, and in meeting your exact product needs. That’s because custom isn’t just something we offer; it’s who we are. For more than 50 years, Pexco has partnered with OEMs, engineers, and manufacturers across North America to create plastic components that solve complex challenges, enhance product performance, and drive innovation.

Whether you know us for a specific extrusion profile, tubing solution, or component line, Pexco’s full range of capabilities goes far beyond any single process. With deep expertise in extrusion, injection molding, machining, and fabrication, along with a powerful foundation in material science and design engineering, we partner with our customers to develop end-to-end plastic solutions that perform, endure, and deliver measurable results.

If you’re already working with Pexco, you’ve experienced our commitment to quality and service. But what many of our customers don’t realize is that Pexco can do much more — often helping streamline operations, consolidate supply chains, and accelerate innovation.

This is your invitation to explore the full scope of what’s possible when you leverage Pexco’s complete suite of custom capabilities.

More Than a Manufacturer — Your Custom Engineering Partner

Pexco isn’t just a plastics manufacturer. We’re a collaborative partner dedicated to turning your vision into reality. Our engineers, designers, and material specialists work side by side with customers from concept through production to ensure every part meets precise specifications for performance, durability, and aesthetics.

Here’s a closer look at our capabilities:

- Custom Extrusions – Extrusion is at the core of what Pexco does—and we’ve perfected it through decades of continuous innovation. From simple single-durometer tubing to complex multi-material and co-extruded profiles, we design and manufacture custom extrusions for demanding applications across telecommunications, aerospace, medical, lighting, and industrial equipment markets. Our capabilities span precision miniature profiles as small as 1/8” to large-format extrusions up to 30” wide, including rigid, flexible, and elastomeric materials. This breadth of expertise allows us to deliver tight-tolerance components with exceptional consistency over long production runs, supported by flexible tooling options and material formulations engineered to meet your exact performance requirements

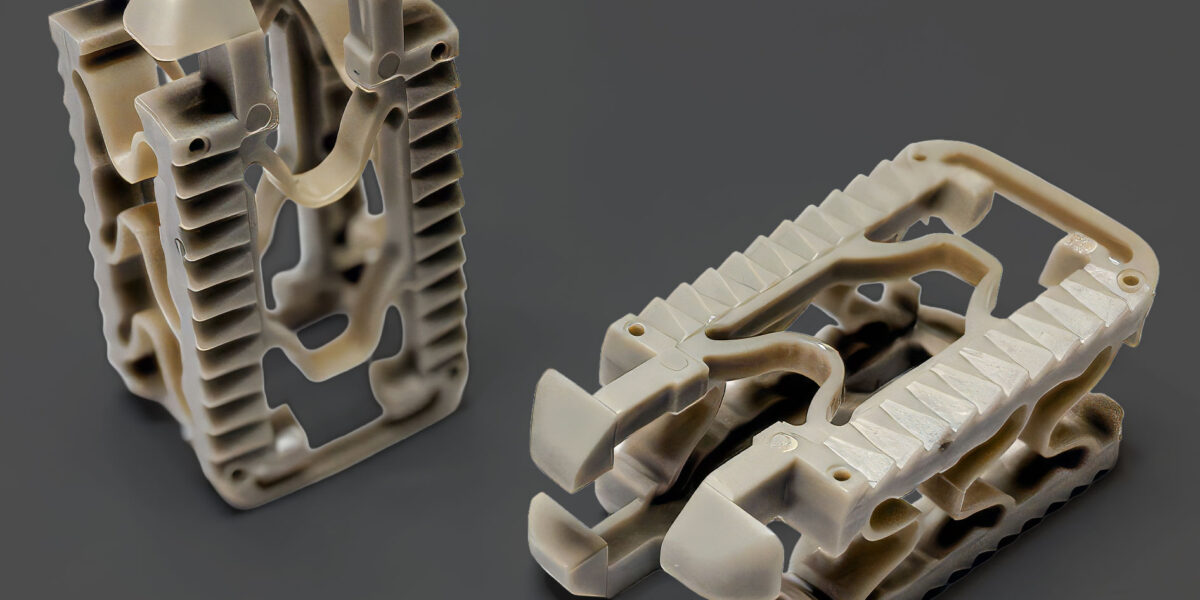

- Injection Molding – Precision injection molding allows Pexco to deliver high-volume, high-performance components that meet strict dimensional and functional requirements. Our molding capabilities support part sizes ranging from small precision components to large, complex assemblies. With specialized expertise in fluoropolymer injection molding, including FEP and PFA, Pexco produces components that provide exceptional chemical resistance, thermal stability, and purity for demanding applications.

We also specialize in compression molding, insert molding, overmolding, and multi-material molding, enabling us to combine different materials and functions within a single part. This approach improves durability, ergonomics, and performance — while reducing assembly steps and potential points of failure.

Whether you need a single molded part or a fully integrated molded-and-machined assembly, Pexco’s custom solutions ensure the best possible combination of efficiency, precision, and design flexibility. - Machining – Pexco’s machining capabilities set us apart in the market. Few manufacturers can machine both plastic and metal, and even fewer can do so while maintaining tight tolerances, consistent quality, and scalable production volumes. From small, high-precision components to large, complex assemblies, Pexco delivers high-performance parts that meet the most demanding dimensional and functional requirements.

- Standard Shapes & Sizes – With the size, reach, and quality standards to deliver consistently, Pexco is the ideal partner for all your stock shape needs. We offer fully customizable tubing and pipe, heat shrink, rods, and sheets—engineered to your exact specifications.

Commitment to Quality and Compliance

At Pexco, quality is not an afterthought — it’s engineered into every part we produce. Our ISO-certified facilities operate under rigorous process controls, ensuring repeatability and compliance across every batch.

We understand the unique regulatory and technical demands of the markets we serve — from AS9100 aerospace standards and FDA medical-grade materials to flame-retardant, UL-listed products for electrical and lighting applications. This commitment to quality and compliance helps reduce your risk, protect your brand, and maintain your reputation for excellence.

Proven Track Record of Partnership

Partnership is at the heart of everything we do. Many of our customers have worked with us for decades because we deliver not only high-quality products but also consistent, responsive service. Our teams are accessible, knowledgeable, and invested in your success.

When you bring Pexco into your design and development process early, you gain a proactive partner who can anticipate challenges, suggest cost-saving opportunities, and accelerate your time to market.

The Power of Customization

Customization is where Pexco truly shines. Because we control every stage of the process — from design and tooling to extrusion, molding, and fabrication — we have the flexibility to tailor every aspect of your part to your exact specifications.

Our engineers can help optimize:

- Design Geometry: Balancing functionality, manufacturability, and aesthetics

- Material Selection: Matching performance needs to polymer properties

- Tooling Design: Ensuring precision, repeatability, and efficiency

- Process Parameters: Controlling temperature, pressure, and cooling for quality outcomes

- Finishing and Assembly: Delivering turnkey, ready-to-install components

The result is a customized solution that not only meets your needs but also adds measurable value — through improved performance, simplified assembly, and reduced total cost of ownership.

Unlock the Full Value of Your Relationship with Pexco

If you’re already a Pexco customer, you’ve seen our dedication to quality and service firsthand. But that’s just one piece of what we can offer. Imagine the benefits of expanding your relationship to include additional product lines, materials, or manufacturing processes — all supported by the same trusted partner who already understands your business.

By deepening your partnership with Pexco, you gain:

- A single-source provider for multiple manufacturing processes

- Access to engineering and design collaboration that drives innovation

- Confidence in quality, compliance, and consistency across every part

- A streamlined supply chain that saves time and reduces risk

- A long-term partner committed to helping you succeed

We believe that great partnerships are built on trust, communication, and shared success. That’s why our team is always looking for new ways to help our customers grow — through advanced technology, creative problem-solving, and a relentless focus on delivering value.

Ready to Do More with Pexco?

Let’s explore what is next. Whether you’re looking to improve an existing design, develop a new product, or consolidate your manufacturing operations, Pexco has the experience, scale, and engineering expertise to make it happen.

Your next innovation starts here.