Understanding the Advantages of FEP and PFA

In industries where parts must perform under intense stress—whether from extreme temperatures, chemical exposure, or friction—fluoropolymers offer a superior material solution. These high-performance plastics are known for their chemical inertness, thermal stability, and mechanical strength, making them ideal for the most demanding applications across sectors like medical technology, aerospace, electronics, chemical processing, and more.

Among the most used fluoropolymers are FEP (fluorinated ethylene propylene) and PFA (perfluoroalkoxy). Both materials are melt-processable fluoropolymers derived from PTFE (polytetrafluoroethylene), and while they share many characteristics, they also have critical differences that make them suitable for different use cases. This blog explores the properties, benefits, and applications of FEP and PFA to help engineers, designers, and material specialists select the right fluoropolymer for their needs.

What Are Fluoropolymers?

Fluoropolymers are synthetic polymers containing fluorine atoms bonded to carbon backbones. This bond is one of the strongest in organic chemistry, giving fluoropolymers their renowned chemical resistance and stability. Some of the most well-known fluoropolymers include:

- PTFE (Polytetrafluoroethylene): Known widely under the brand name Teflon™, PTFE is non-melt processable but highly resistant to heat and chemicals.

- FEP (Fluorinated Ethylene Propylene): A melt-processable version of PTFE with better clarity and flexibility.

- PFA (Perfluoroalkoxy): Like FEP but offers higher temperature resistance and improved mechanical properties.

These materials are widely used in applications that demand long-term reliability under harsh environmental conditions. The performance benefits of fluoropolymers include:

FEP: Fluorinated Ethylene Propylene

FEP is a melt-processable fluoropolymer that offers a balance of performance and affordability. It inherits many of the chemical and thermal resistance properties of PTFE but differs in that it can be extruded and injection molded, making it a versatile option for manufacturing complex parts.

Key Properties of FEP:

- Low Gas and Vapor Permeability: This makes FEP well-suited for use in containment and barrier applications where protection against moisture or gas ingress is critical.

- UV Transparency: FEP offers excellent UV transmission, making it valuable in environmental monitoring and solar applications.

- Gamma Sterilizability: Its ability to withstand sterilization processes makes FEP a viable option for medical and pharmaceutical applications.

- Thermal Resistance: FEP can operate continuously at temperatures up to 400°F (204°C).

- Chemical Inertness: Compatible with nearly all chemical compounds, acids, and solvents.

- Flexibility: It can be heat-formed, tipped, tapered, flared, and flanged, supporting a wide range of component designs.

Common Applications of FEP:

- Medical tubing and catheters

- Laboratory equipment

- Wire and cable insulation

- Semiconductor processing parts

- Environmental monitoring devices

Challenges with FEP:

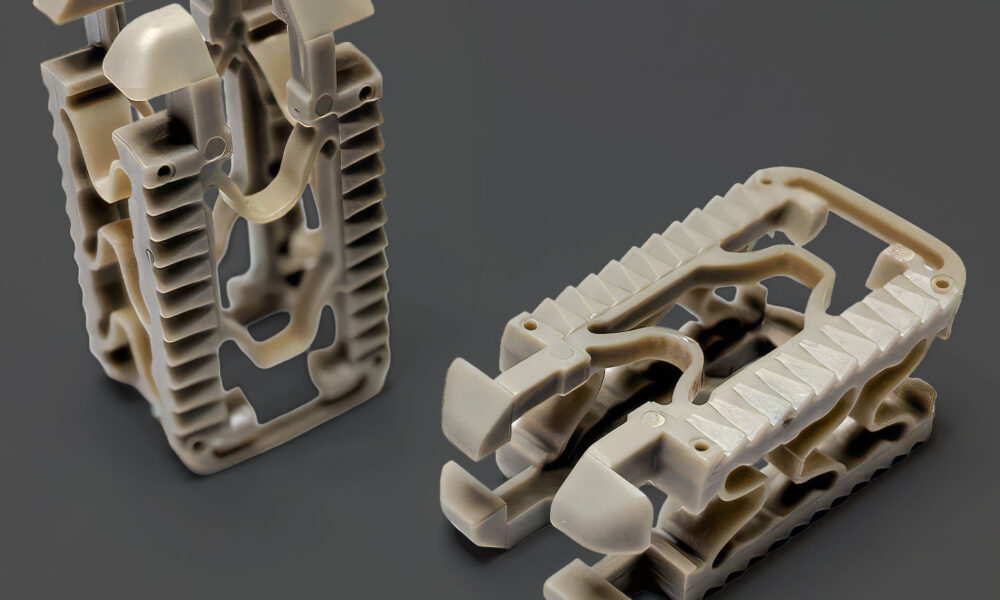

One of FEP’s main challenges is its low melt viscosity, which makes it difficult to mold into small or complex geometries. However, companies like Pexco have developed proprietary tooling and manufacturing techniques to overcome this challenge. By refining injection molding methods and using specialized equipment, they can successfully produce small, thin-walled, complex FEP components with precision.

PFA: Perfluoroalkoxy

PFA is another melt-processable fluoropolymer that builds upon the advantages of both PTFE and FEP. It provides improved mechanical properties, higher temperature tolerance, and superior surface finish. It is considered one of the most robust fluoropolymers available for commercial use.

Key Properties of PFA:

- Higher Continuous Service Temperature: PFA can operate at up to 500°F (260°C), making it suitable for the most thermally challenging environments.

- Excellent Flow Properties: Its molecular structure allows it to flow more easily during molding, enabling better reproduction of intricate part geometries.

- Superior Creep Resistance: PFA resists deformation under long-term stress, making it ideal for structural or load-bearing components.

- Smoother Surface Finish: This reduces the potential for buildup of contaminants or particles, which is essential in cleanroom and semiconductor environments.

- High Tensile Strength: PFA offers greater mechanical integrity than PTFE and FEP, especially at elevated temperatures.

Common Applications of PFA:

- Semiconductor wafer processing components

- Aerospace fluid handling systems

- High-purity chemical transport tubing

- Oil and gas industry valves and seals

- Pharmaceutical manufacturing equipment

Considerations When Using PFA: While PFA is easier to mold than FEP and offers higher performance in many areas, it comes at a significantly higher cost—often up to three times that of FEP. Therefore, the choice to use PFA should be based on the application’s need for elevated performance in extreme environments.

FEP vs. PFA: A Side-by-Side Comparison

| Property | FEP | PFA |

| Maximum Temperature | 400°F (204°C) | 500°F (260°C) |

| Chemical Resistance | Excellent | Excellent |

| Moldability | Difficult due to low viscosity | Easier due to improved flow |

| Transparency | Higher | Slightly lower |

| Surface Finish | Good | Excellent |

| Tensile Strength | Moderate | High |

| Gamma Sterilizability | Yes | Yes |

| Creep Resistance | Moderate | High |

| Cost | Lower (~⅓ the cost of PFA) | Higher |

When choosing between FEP and PFA, the decision often hinges on the specific requirements of the application—particularly temperature resistance, molding complexity, and budget constraints.

Industry Use Cases and Material Selection

Fluoropolymers have become essential materials in numerous sectors. Their usage is not only driven by performance requirements but also regulatory and safety standards:

- Semiconductor Industry: PFA is a preferred material due to its high purity, chemical resistance, and thermal stability. It is used in wafer handling systems, tubing, and fittings.

- Medical Devices: FEP’s biocompatibility, clarity, and sterilizability make it ideal for tubing and catheters.

- Chemical Processing: Both FEP and PFA are used to line pipes, tanks, and valves to protect against aggressive chemicals.

- Aerospace and Automotive: These materials are utilized in fluid and fuel transport systems where durability and resistance to harsh conditions are required.

- Pharmaceutical Manufacturing: PFA is commonly used for components in cleanroom environments due to its smooth surfaces and contamination resistance.

PEXCO: Fluoropolymer Molding Experts

At Pexco, we specialize in high-precision injection molding of ultra and high-performance thermoplastics, including FEP and PFA. With decades of experience, our engineering team has developed proprietary tool design software and processes that allow us to manufacture parts with complex geometries using even the most difficult-to-mold materials. We are uniquely equipped to deliver components that must meet stringent requirements for thermal stability, chemical resistance, dielectric strength, and mechanical integrity—even at micro-scale dimensions

Need Help Selecting the Right Material?

Choosing between FEP and PFA requires a careful assessment of your application’s performance demands, design constraints, and budget. At Pexco , our team is ready to support you from material selection to final production, ensuring optimal results for your project.

For more information on Pexco’s Injection Molding & Extrusion capabilities, please request information at pexco.com/contact-us.