Our Products

Our Brands

Markets

Capabilities

About Pexco

Aerospace & Defense Plastics Solutions

Precision, Performance, Reliability

For over 60 years, Pexco has partnered with leading aerospace and defense manufacturers to deliver lightweight, high-performance polymer components that meet the most demanding requirements. With the acquisition of Precise Aerospace Manufacturing in 2024, Pexco expanded its aerospace capabilities to include advanced molding, sub-assembly, and machining of high-performance polymer and metal components. From molded, extruded, and assembled parts to precision-machined components, we engineer solutions that help aircraft fly safer, lighter, and more efficiently.

Market Challenges

The aerospace and defense industry faces relentless pressure to improve performance, reduce weight, and comply with stringent safety and regulatory standards. Materials must perform reliably in extreme environments, with full traceability and quality control.

Top Challenges in the Aerospace and Defense Industry

- Reducing weight without sacrificing strength or durability

- Meeting flame, smoke, and toxicity (FST) regulations

- Achieving tight tolerances and precision in custom components

- Ensuring material traceability and compliance with aerospace standards

- Delivering consistent quality for mission-critical applications

Precise Aerospace Solutions

Precise’s products and capabilities help solve these challenges by combining materials expertise with advanced manufacturing.

Products for Aerospace & Defense

Our Capabilities

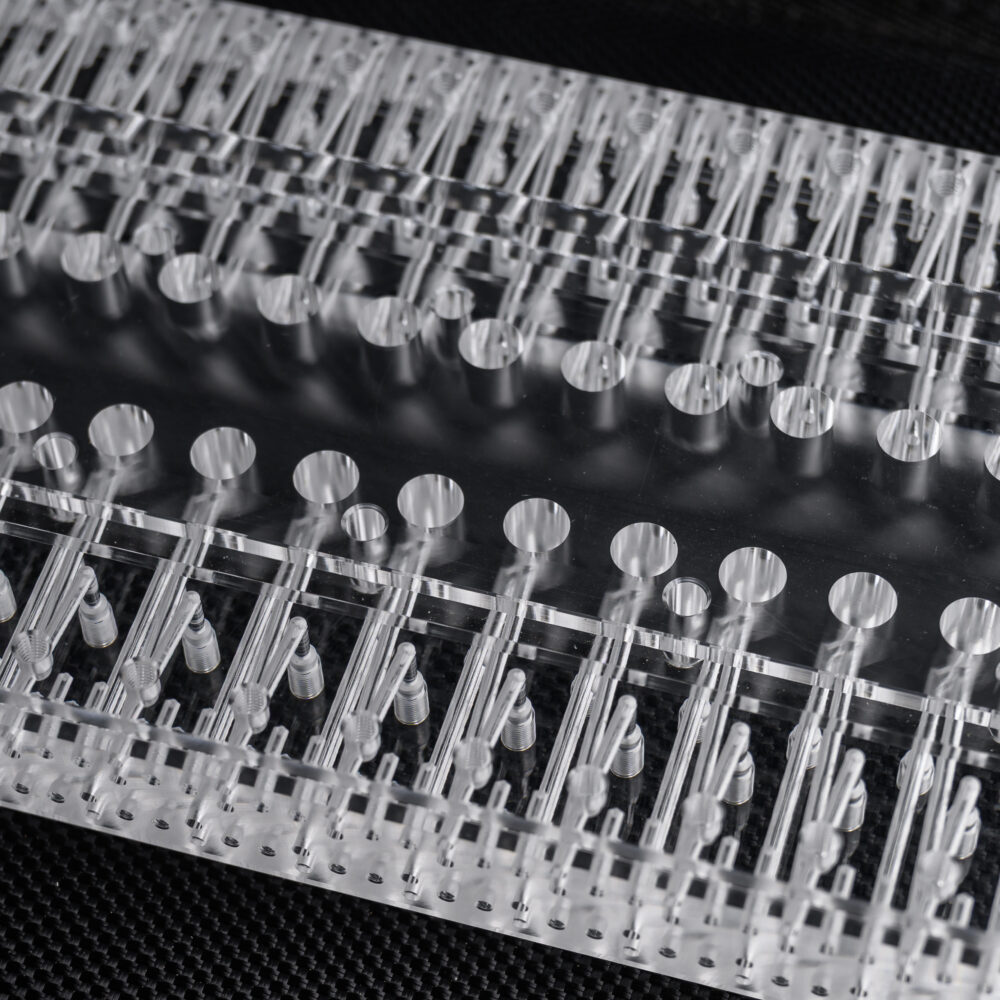

Precision injection molded components

Compression, insert, and transfer molded parts

Precision CNC machined polymer and metal components

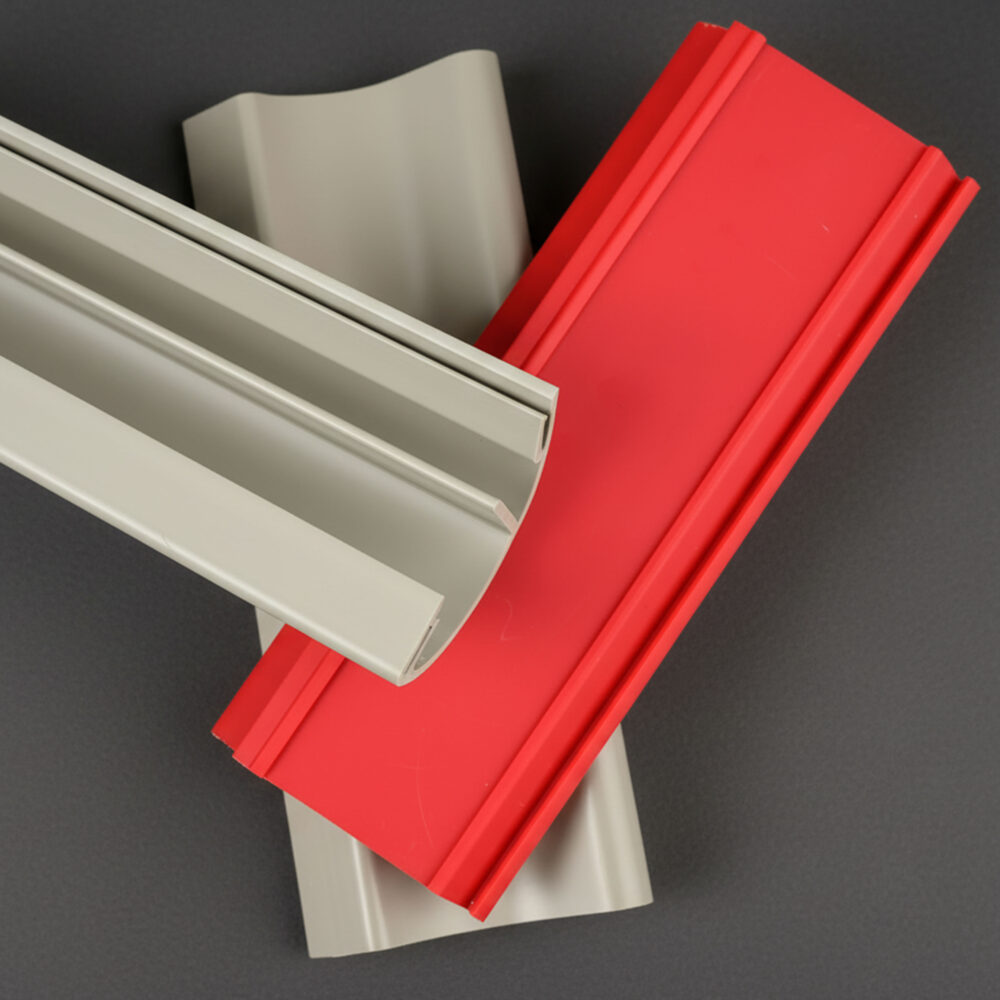

Plastic extrusion of tubing and profiles

Sub-assemblies of integrated components, kitting, and secondary operations

Material selection and engineering support

Materials Expertise

Precise’s high-performance material offerings are molded, machined, and assembled by Pexco and Precise Aerospace into flight-critical components requiring repeatability, structural integrity, and long-term performance.

Common Aerospace Polymers

PEEK

High strength-to-weight ratio, excellent chemical and thermal resistance. Used for lightweight structural and mechanical components.

Fluoropolymers (PTFE, FEP, PFA)

Low friction, chemical resistance, and dielectric strength for seals, liners, and insulations applications.

PAI (Torlon®)

Ultra-high strength and rigidity, excellent wear and friction performance, dimensional and thermal stability, and chemical resistance. Ideal for bushings, bearings, and structural components that must withstand continuous thermal and mechanical stress.

PEI (Ultem®)

High temperature resistance and inherent flame retardancy for electrical and interior components.

Nylon & Acetal

Wear resistance and machinability for bushins, gears, and precision parts.

Silicone & Fluorosilicone

Thermal stability and fuel resistance

EDPM

Ozone and UV protection

TPV/TPE

Light, flexible, and easy to process for non-critical applications

Compliance and Certifications

Precise’s aerospace operations adhere to strict industry standards:

- AS9100 (aerospace quality management)

- ISO 9001

- FAR 25.853 FST (flame, smoke, toxicity compliance)

- CMMC Level 2 approval

- Full traceability of materials and process

Why Precise?

Domestic Manufacturing Footprint

U.S. operations with aerospace-certified facilities

Deep Materials Expertise

Decades of polymer engineering knowledge

Custom Engineering

From concept to prototype to production

Proven Partner

Long history serving aerospace OEMs and Tier 1 suppliers

Integrated Capabilities

Extrusion, molding, machining, and assembly under one roof