Our Products

Our Brands

Markets

Capabilities

About Pexco

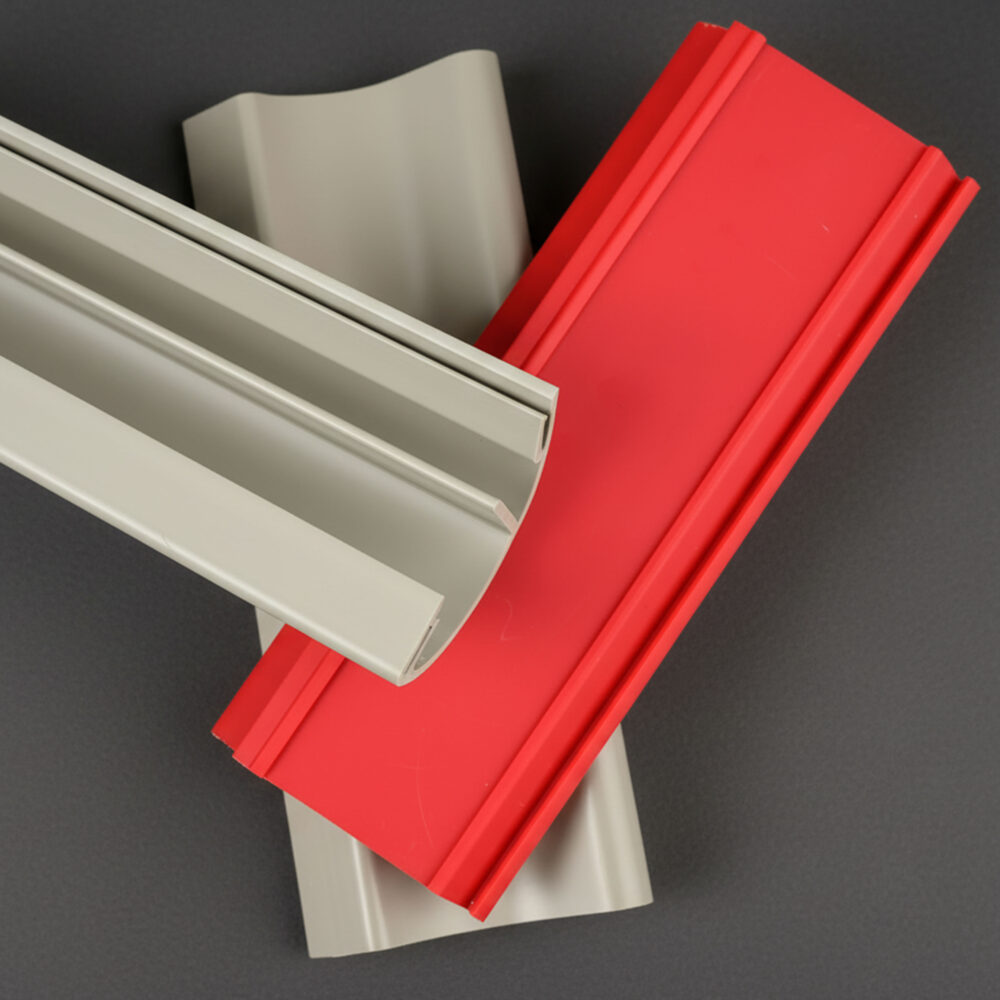

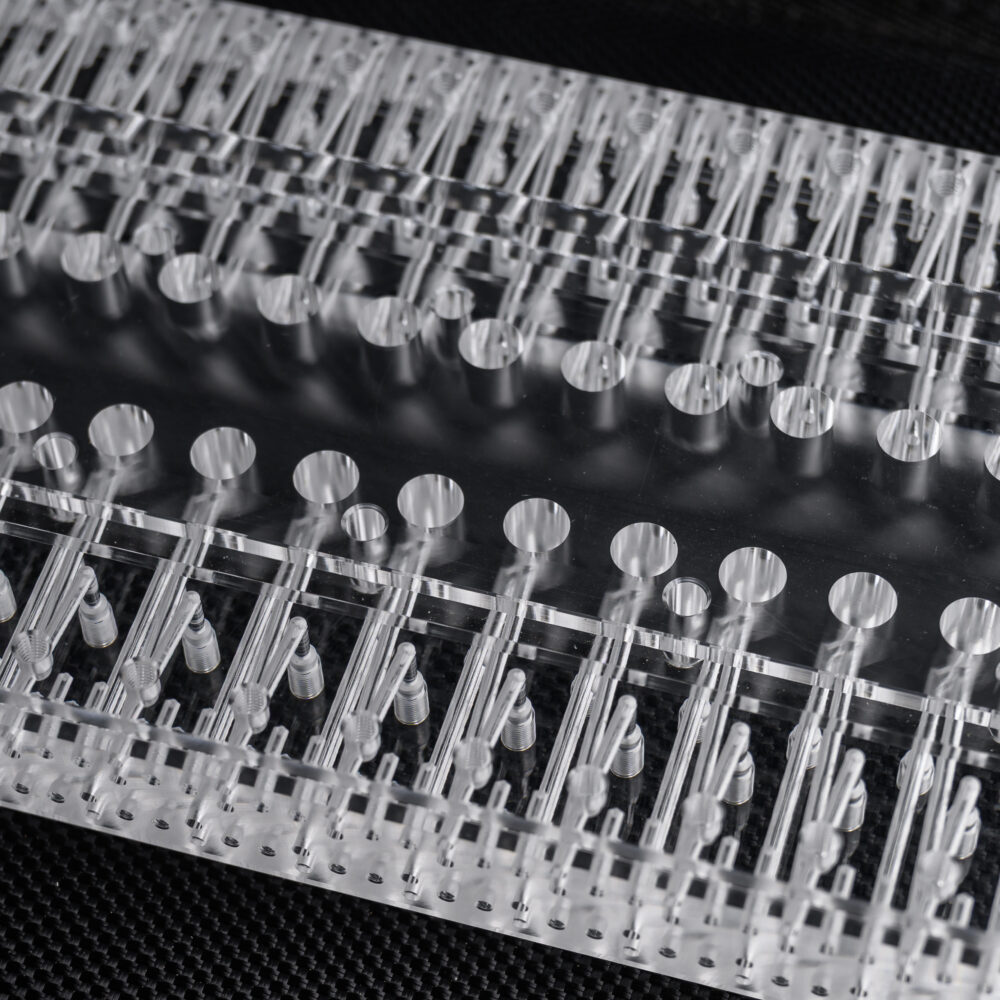

Electrical and Electronics Plastics Solutions

The Electrical and Electronics industry depends on plastic for its insulation properties, just as much as it depends on metals for its conductive properties. For over 40 years, Pexco has been producing extruded, molded and machined plastic parts to make electrical applications safer and more reliable.

Market Challenges

Electronics drive the modern world and influence everything we do. From the phones in our pockets to the satellites orbiting the earth, electricity is constantly in use around us, in ways that we don’t even think of. As the use of electricity and electronic devices becomes more ubiquitous, and we rely on our devices more and more, Pexco is positioned to meet the demands of the Electrical and Electronics industry.

Top Challenges

- Achieving tight tolerances and precision in custom components

- Maintaining complex supply chains

- Keeping up with rapidly changing technology

Pexco Solutions

Pexco’s products and capabilities help solve these challenges by combining materials expertise with advanced manufacturing and integrated production capabilities, all within a domestic footprint.

Products for Electrical and Electronics

Our Capabilities

Plastic extrusion

Injection and compression molding

Precision CNC machining

Secondary operations (bonding, drilling, finishing)

Assembly and kitting

Material selection and engineering support

Materials Expertise

Every application starts with the right material. Pexco’s extensive expertise helps match polymers to demanding market requirements.

PTFE

High dielectric strength and low dielectric constant and dissipation factor make it an excellent insulator

PEEK

High strength-to-weight ratio, good machinability, and high dielectric strength

Fluoropolymers (PTFE, FEP, PFA)

High dielectric strength, low coefficient of friction, and unsurpassed chemical resistance

PEI (Ultem®)

Excellent dimensional stability and dielectric strength

Nylon

Durable, flexible, and thermally stable

Silicone

High dielectric strength, thermally stable, and weatherproof

Polyolefin and PVC

Durable, flexible, and economical

Compliance and Certifications

Pexco Electrical and Electronics products comply with the following standards (where applicable):

- ISO 9001

- UL 224-VW-1

- SAE AS 23053/*

- ASTM D 3150

- Mil-I-631

Why Pexco?

Domestic Manufacturing Footprint

U.S. operations with aerospace-certified facilities

Materials Expertise

Decades of polymer engineering knowledge

Custom Engineering and Design

Offers engineering support from concept to prototype to production

Integrated Capabilities

Provides extrusion, molding, machining, and assembly services through a single point of contact

Scalability

Capable of supporting prototype quantities through full-scale productions runs