Our Products

Our Brands

Markets

Capabilities

About Pexco

Semiconductor Plastics Solutions

Purity, Precision, Performance

Pexco delivers high-performance polymer components for semiconductor fabs, OEMs, and data centers. From ultra-pure fluoropolymer tubing to precision-machined parts, our solutions support the industry’s most demanding applications—from chemical delivery to liquid cooling and advanced packaging.

Market Challenges

The semiconductor industry demands ultra-clean, chemically resistant, and dimensionally stable components across multiple segments. Pexco targets Infrastructure, Wet Process, and CMP—where plastics are most critical. AI, IoT, Advanced Packaging and Nanotechnology are driving the rapid growth of the semiconductor market, from new chip design with new materials (e.g., ESD components to handle corrosive solvent) tool and process development. With the forecasted 2x growth by 2030, supply chain assurance to avoid fab interruption will be critical.

Top Challenges

- Infrastructure: Long-term durability, DI water compatibility, and installation efficiency

- Wet Process: Ultra-high purity, chemical inertness, and cleanroom compliance

- CMP: Abrasion resistance, tight tolerances, and material innovation

- Cross-Segment Needs:

- SEMI F57, C90, and F104 compliance

- Qualification and approval at fabs and OEMs

- Short lead times and supply assurance

- Resistance to aggressive chemistries and high temperatures

Pexco Solutions

Pexco’s products and capabilities help solve these challenges by combining materials expertise with advanced manufacturing.

Products for Semiconductor by Segment

Infrastructure

UHP PFA for Chemical Delivery

PVDF pipes for DI water systems

PTFE pipes for insulation

Custom profiles for fiberoptic raceways

Elastomer seals and gaskets for HVAC and cooling systems

Heat shrink tubing for electrical cables

Wet Process

UHP PFA tubing for chemical delivery

PTFE rods and shapes for heat exchangers

CMP

THV and THV alternatives for polishing systems

Skived PTFE film for chamber liners

PTFE shapes for wet pump bodies

Dry Process

PTFE skived films for liners

Chemical Delivery Systems

UHP PFA tubing for chemical delivery

Pexco’s Manufacturing Capabilities

- Plastic extrusion (cleanroom extrusion and molding)

- Injection and compression molding

- CNC machining and secondary processing (etching, bonding)

- Material selection support

- Laser marking and in-line cutting

- Dual extrusion and double containment tubing

- Engineering support and white paper development

- Assembly and kitting

Materials Expertise

Every application starts with the right material. Pexco’s extensive expertise helps match polymers to demanding semiconductor requirements.

Common Semiconductor Materials

High purity, chemically inert materials ideal for wet process, CMP, and chemical delivery systems.

- UHP PFA – Highest purity, lowest permeation; used in chemical delivery systems and CMP tools

- PFA – Excellent chemical resistance and thermal stability; used in tubing, pipe, and fittings

- HP PFA – High purity variant for demanding wet process applications

- PVDF – Weldable and durable; used in DI water systems and infrastructure piping

- PTFE – Superior thermal and chemical resistance; used in heat exchangers, pump bodies, and insulation inserts

- FEP – Transparent and inert; used in visual inspection tubing and dielectric applications

- ECTFE – Exceptional chemical resistance and mechanical strength; ideal for acid and solvent containment, exhaust systems

- THV – Flexible and chemically resistant for CMP; sourcing alternatives underway/col

Versatile engineering plastics used in structural, fluid handling, and electrical applications.

- PEEK – High strength-to-weight ratio; used in wafer handling and precision components

- PSU (Polysulfone) – High strength and hydrolytic stability; used in filtration housings and fluid control systems

- PPSU – Chemically resistant and tough; used in hydrogen electrolyzers and fluid control

- PEI (Ultem®) – High temperature resistance and flame retardancy; used in electrical insulation and structural parts

- HDPE – Cost-effective and chemically resistant; used in drainage and protective conduit

- CPVC – Higher temperature tolerance than PVC; used in DI water and chemical waste lines

- Polycarbonate & Acrylic – Transparent and impact-resistant; used in protective housings and inspection tools

Used for wire harnessing, insulation, and cleanroom-compatible bundling.

- Heat Shrink PVC – Economical insulation and bundling; used in non-critical wire harnesses

- Polyolefin (Poly-O) – Flame-retardant and flexible; used for wire identification, strain relief, and cleanroom electrical assemblies

Flexible, sealing-grade materials used in gaskets, connectors, and fluid systems.

- EPDM – Excellent weather and ozone resistance; used in seals, gaskets, and flexible connectors for utility systems

- Silicone – Premium elastomer for high-performance sealing in OEM tools/acc

| Category | Material | Pexco Trade Name(s) | Semiconductor Use Case |

|---|---|---|---|

| Fluoropolymers | UHP PFA | Altaflo® 480 Series | Ultra-pure chemical delivery systems, CMP tools |

| PFA | Altaflo® | Tubing, pipe, fittings for wet process and infrastructure | |

| HP PFA | Altaflo® HP Series | High purity wet process applications | |

| PTFE | Enflon® | Heat exchangers, pump bodies, insulation insert | |

| FEP | Altaflo® FEP | Visual inspection tubing, dielectric applications | |

| ECTFE | — | Acid/solvent containment, chemical exhaust systems | |

| Thermoplastics | PVDF | Altaflo® PVDF | DI water systems, infrastructure piping |

| PEEK | — | Wafer handling, precision components | |

| PSU | — | Filtration housings, pump components | |

| PPSU | — | Hydrogen electrolyzers, fluid control systems | |

| PEI (Ultem®) | — | Electrical insulation, structural components | |

| HDPE | — | Drainage systems, protective conduit | |

| CPVC | — | DI water and chemical waste lines | |

| Polycarbonate & Acrylic | — | Protective housings, visual inspection tools | |

| Heat Shrink | Heat Shrink PVC | — | Wire harnesses, protective sleeving |

| Polyolefin (Poly-O) | — | Wire ID, strain relief, cleanroom electrical assemblies | |

| Elastomers | EPDM | — | Seals, gaskets, flexible connectors for utility systems |

| Silicone | — | High-performance seals and gaskets for OEM process equipment |

Compliance and Certifications

Pexco’s semiconductor operations adhere to strict industry standards:

- SEMI F57, C90, F104

- ISO 9001

- Cleanroom manufacturing protocols

- Full traceability and laser marking

- Third-party cleaning and packaging for semi-rated parts

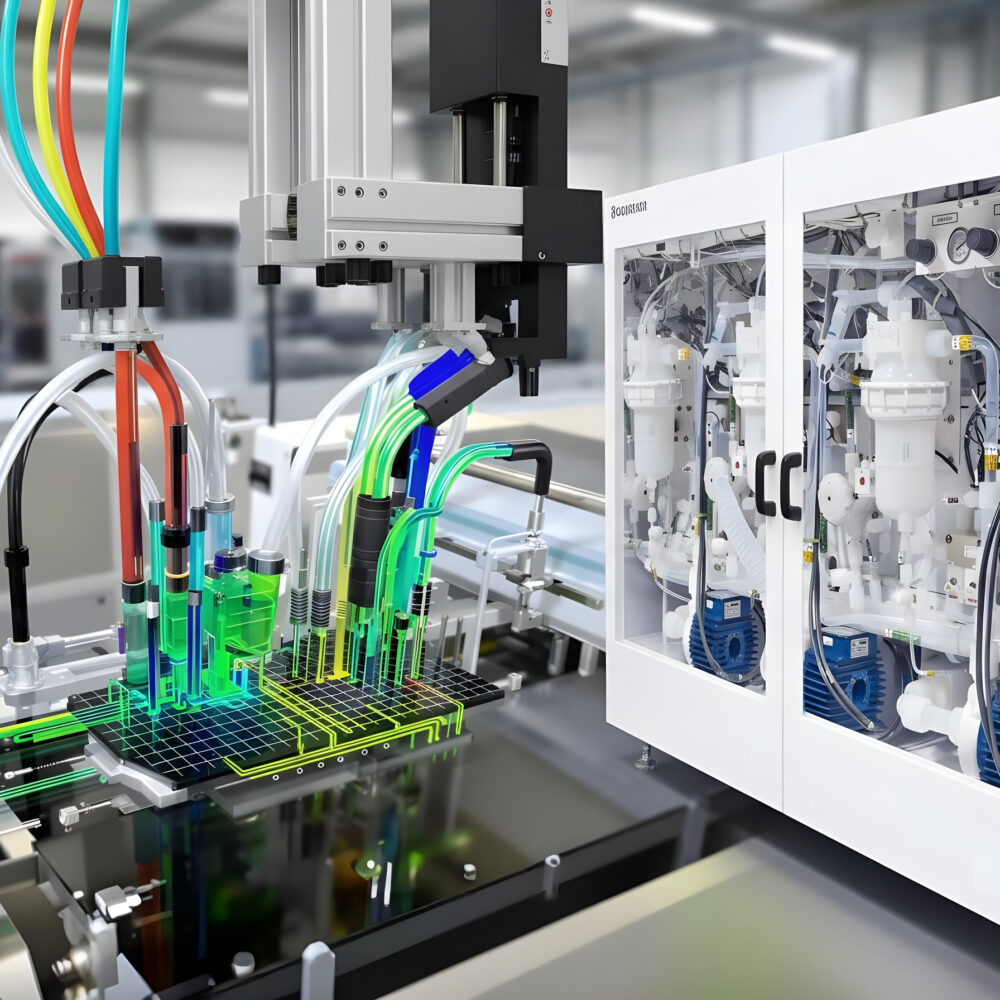

Advanced Manufacturing & Assembly Capabilities

Pexco isn’t just a material supplier — we’re a full-spectrum solutions provider for the semiconductor industry. Our machining, injection molding, and contract assembly services are designed to meet the precision, purity, and scalability demands of fabs, OEMs, and system integrators.

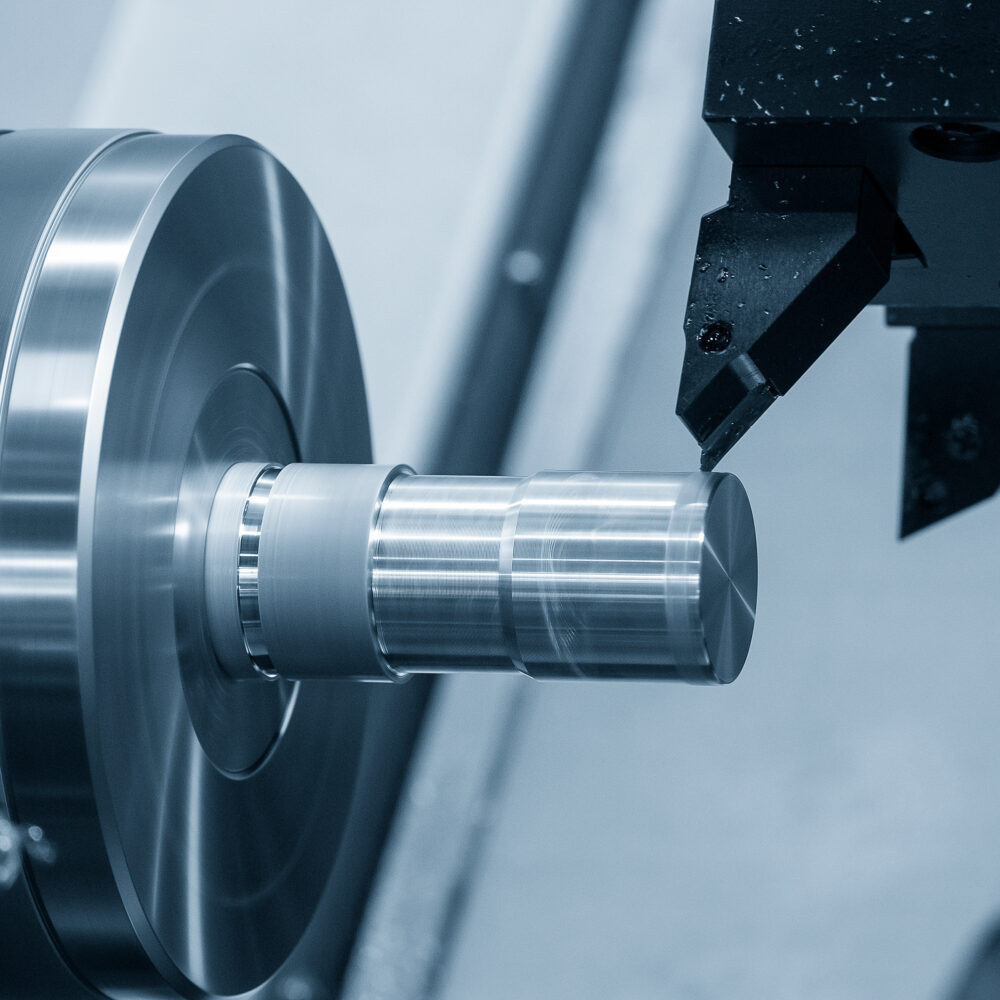

Precision Machining

- Micron-level tolerances for critical components in CMP, wet process, and backend test systems

- Expertise in PTFE, PFA, PVDF, and FEP stock shapes for heat exchangers, pump bodies, and insulators

- Cleanroom-compatible machining with full traceability and laser marking

- Ideal for Copy Exact environments requiring repeatable, validated parts

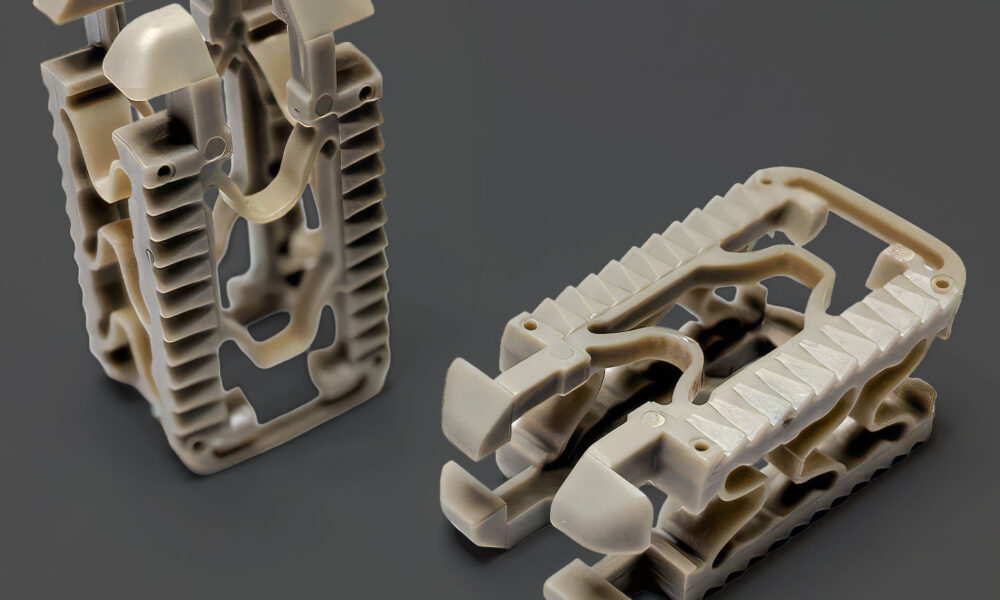

Injection Molding

- High-performance molding of fluoropolymers and engineering plastics for semiconductor-grade fittings, seals, and housings

- Supports complex geometries and high-volume production with tight process control

- Molded parts meet SEMI F57, C90, and F104 standards for extractables and particle contribution

- Integrated with ISO 9001-certified quality systems

Contract Assembly & Kitting

- Micron-level tolerances for critical components in CMP, wet process, and backend test systems

- Expertise in PTFE, PFA, PVDF, and FEP stock shapes for heat exchangers, pump bodies, and insulators

- Cleanroom-compatible machining with full traceability and laser marking

- Ideal for Copy Exact environments requiring repeatable, validated parts

Case Study

UHP PFA Tubing for Wet Process Equipment

Challenge

OEM required ultra-high purity tubing for chemical delivery systems in wet etch and clean modules. The tubing needed to meet SEMI F57, F104, and ISO 9001 standards, with full traceability and rapid delivery.

Solution

- Pexco supplied UHP PFA tubing extruded in a cleanroom environment with laser marking for traceability

- Tubing was cleaned and packaged by a third party certified for semiconductor-rated parts

- Materials were tested and documented to meet SEMI F57 extractables and F104 particle contribution standards

- Delivered within 2 weeks—significantly faster than competitors

Outcome

- Approved for use in multiple wet process tools

- Customer expanded orders to include additional tubing diameters and profiles

- Pexco became a preferred supplier for high-purity tubing

Case Study

PTFE Rods for Heat Exchanger Components

Challenge

Required PTFE rods for machining into heat exchanger components. Needed ISO 9001-certified production, SEMI C90 compliance for cleanliness, and secondary processing (etching) for bonding.

Solution

- Pexco provided PTFE stock shapes manufactured under ISO 9001 protocols

- Rods were etched and cleaned to meet SEMI C90 standards

- Delivered with full traceability documentation and batch-level laser marking

- Packaged in cleanroom-compatible containers by a third party

Outcome

- Customer qualified Pexco as a vendor for multiple fab installations

- Pexco expanded offering to include machined PTFE components for pump bodies

Case Study

High-Purity Valve Bodies Using Pexco PTFE

Challenge

A leading OEM specializing in wet process equipment for semiconductor fabs, including chemical delivery systems and fluid control modules, needed valve bodies capable of withstanding aggressive chemistries (e.g., HF, HCl, H₂SO₄) used in wafer cleaning and etching processes.

Solution

Pexco supplied machined PTFE valve bodies using its proprietary Enflon® PTFE stock shapes, known for:

- Ultra-low extractables and particle generation

- Excellent chemical resistance and thermal stability

- Smooth surface finish to minimize particle entrapment

- Compatibility with secondary processing (etching, bonding)

Value-Added Services Included

- Cleanroom machining with micron-level tolerances

- Laser marking for full traceability

- Third-party cleaning and double-bag packaging for semi-rated parts

- Engineering support for design optimization and SEMI compliance documentation

Outcome

- Valve bodies passed qualification testing and were approved for use in multiple wet process tools

- Customer reduced lead time by 40% compared to previous supplier

- Pexco was added to the OEM’s preferred vendor list for machined fluoropolymer components

- Follow-on orders included PTFE pump bodies and manifold blocks

Why Pexco?

Ultra-Pure Manufacturing Standards

Cleanroom extrusion and climate-controlled facilities ensure compliance with SEMI F57, C90, and F104 standards for purity, particle control, and extractables

Fast, Reliable Delivery

Pexco’s short lead times and responsive customer service consistently outperform competitors, helping customers meet tight installation and production schedules

Full Traceability & Quality Assurance

Laser marking, batch-level documentation, and ISO 9001-certified processes provide complete traceability and confidence in every part delivered

Strategic Product Portfolio

Offering UHP PFA, PTFE, PVDF, and THV tubing and shapes for chemical delivery, cooling, and CMP—plus expansion into fittings, ESD products, and skived films

Proven Success with Fabs & OEMs

Altaflo PFA, FEP, THV and other materials have been used by Samsung, Texas Instruments, Intel, Micron, AMAT and LAM Research. Formal qualifications are underway