The Engineer’s Secret Weapon for Injection Molding Success

In the world of precision engineering, there’s little room for guesswork, especially when it comes to injection molding. The success of any molded part depends not just on its design or materials, but on how well those materials behave during the molding process. That’s where mold flow analysis (MFA) enters the equation.

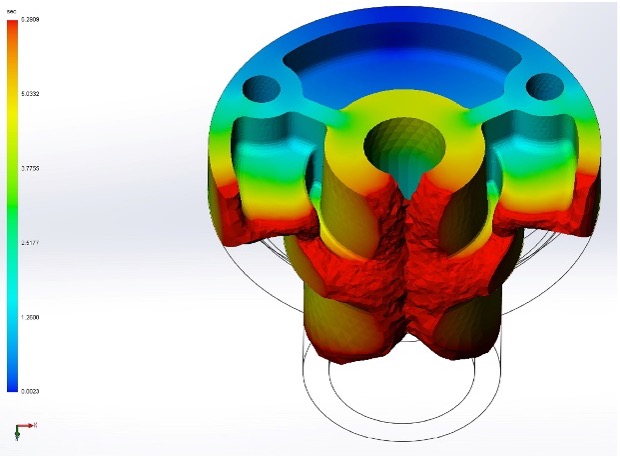

Mold flow analysis is a powerful simulation tool that predicts how molten plastic will flow through a mold cavity during injection molding. With the ability to visualize flow patterns, pressure points, weld lines, and cooling behavior before physical tooling is made, engineers can proactively optimize product design, improve manufacturability, and significantly cut down development costs.

Let’s take a deep dive into why every engineer involved in part design or mold development should be leveraging mold flow analysis and how doing so can unlock measurable performance and cost advantage.

What Is Mold Flow Analysis?

Mold flow analysis is a computer-aided engineering (CAE) simulation that provides detailed insights into how a thermoplastic or thermoset material fills, packs, cools, and warps inside a mold cavity. It models physical behaviors including:

- Material flow and viscosity changes

- Heat transfer and cooling rate

- Gate location effects and pressure drops

- Knit/weld line formation

- Residual stresses and shrinkage

This digital process enables engineers to virtually mold the part before any tooling investment, thereby ensuring potential issues are resolved proactively rather than retroactively.

Six Key Reasons Engineers Rely on Mold Flow Analysis

1. Design Optimization Without Physical Tooling

Before cutting steel, mold flow analysis gives you a virtual proving ground for your designs. It answers the critical “what-if” questions without incurring the cost of physical prototypes or tools.

Engineers can validate and refine:

- Wall thickness: Avoid sink marks, voids, or short shots caused by overly thin or thick sections.

- Geometry: Detect fill hesitations, air traps, and knit lines in complex shapes.

- Material compatibility: Analyze how different resins behave in your part geometry.

- Stress profiles: Identify areas likely to warp or deform post-molding.

Ultimately, you’re designing with confidence, not assumptions.

2. Rapid, Data-Driven Decision Making

Mold flow simulations provide quick feedback loops that empower engineers to make informed, timely decisions about:

- Gate types and placements

- Venting strategy

- Material selection

- Cycle time targets

- Cooling and ejection planning

This agility is especially useful during early-stage development or iterative design reviews. With mold flow data in hand, teams can align on production goals faster and minimize delays caused by unforeseen design flaws.

3. Optimized Mold and Tooling Design

Beyond part geometry, mold flow analysis enables engineers and tooling designers to co-optimize the entire mold system. You can simulate and refine:

- Gate and runner layout for balanced filling

- Cooling channel configurations for thermal uniformity

- Packing pressures to avoid overfill or warpage

- Cavity layout for multi-cavity molds

- Tool life by analyzing stress concentrations in the mold steel

The result? Molds that run more efficiently, require less maintenance, and produce better parts from the very first shot.

4. Material Testing Without Cutting Metal

Testing new materials no longer requires running expensive prototypes. With MFA, you can virtually simulate:

- Flow behavior of multiple grades of resin

- Viscosity response to temperature and pressure changes

- Shrinkage and warpage tendencies unique to each material

- Impact of fiber orientation (in glass-filled materials) on mechanical strength

This allows you to experiment with bio-resins, flame-retardant compounds, or high-heat polymers—without the risk of costly surprises during trial runs.

5. Reduced Cycle Time and Energy Costs

One of the most overlooked benefits of mold flow analysis is its ability to optimize the overall cycle time—a direct lever on your plant’s throughput and cost efficiency.

By refining fill, pack, and cool phases through simulation, engineers have achieved cycle time reductions of 10–30%, depending on part complexity and tooling configuration. These savings:

- Free up machine capacity

- Reduce energy consumption

- Lower wear-and-tear on molds

- Improve part-to-part consistency

Even a 10% reduction on a high-volume part can translate to tens of thousands of dollars in annual savings.

6. Machine and Process Specification Tuning

MFA enables precise simulation of how a part will behave under a specific machine configuration. Engineers can virtually match:

- Injection speed and pressure curves

- Clamp force and cooling system settings

- Cycle time and shot volume

- Process DOE parameters

This simulation-driven approach helps fine-tune process windows, which is critical when transitioning from prototype to high-volume production. It also reduces setup time and scrap rates during machine trials.

Why Mold Flow Analysis Should Be a Standard Engineering Tool

Mold flow analysis isn’t just a “nice-to-have” anymore—it’s a foundational tool in the engineer’s toolkit for competitive, high-quality injection molded parts. By investing a relatively small amount of time and budget up front, companies can reap long-term benefits, including:

- First-time-right tooling

- Fewer engineering changes (ECOs)

- Accelerated time-to-market

- Reduced manufacturing risk

- Higher product quality

With increasing pressure to shorten development cycles and improve part performance, engineering teams that embrace mold flow analysis early in the design phase are consistently outperforming their peers.

As engineers, we strive to build better, faster, and smarter. Mold flow analysis is one of the most effective ways to engineer-out problems before they occur. It turns injection molding into a predictable science rather than an expensive art form—and the results speak for themselves.

At Pexco, we specialize in providing mold flow analysis to help engineering and manufacturing teams streamline product development, optimize tooling, and ensure consistent part performance.

To explore how our team can support your next project, reach out to Dana Scott, Director of Market Development at [email protected].