Our Products

Our Brands

Markets

Capabilities

About Pexco

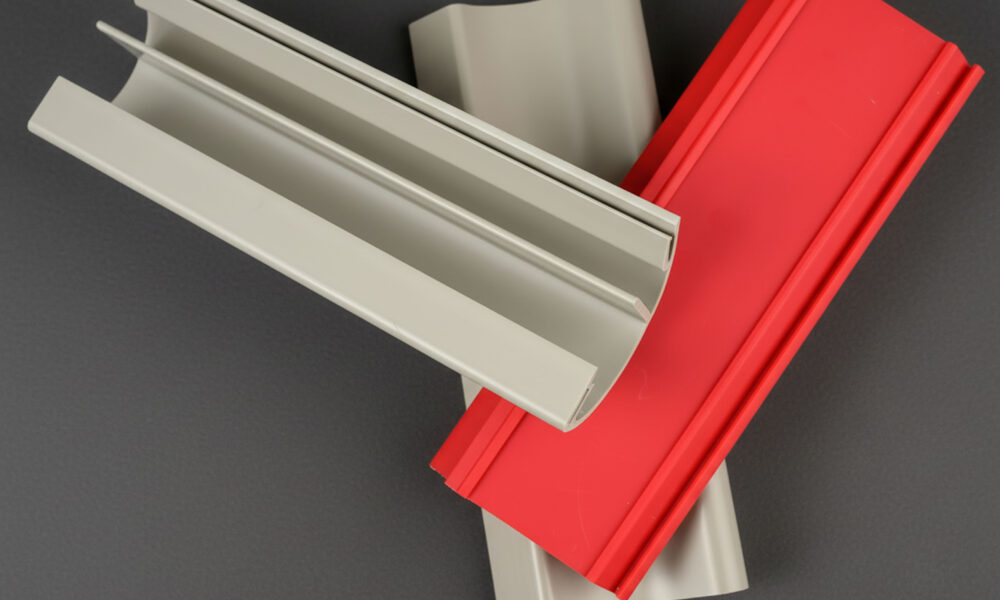

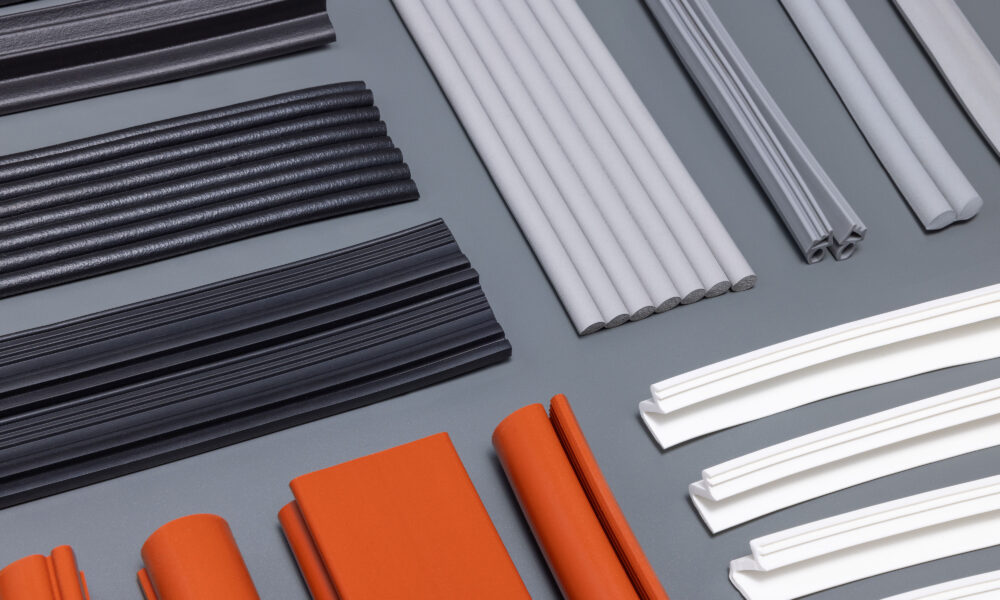

Elastomer Extrusions

Pexco manufactures a wide range of elastomer extrusions, including dense and sponge profiles, cords, and tubing engineered for sealing, cushioning, insulation, and vibration damping. Elastomers offer exceptional flexibility, durability, and chemical resistance, making them ideal for demanding industrial, commercial, and environmental applications.

Customized to Your Application Requirements

Customers choose Pexco because we collaborate closely on every extrusion project and tailor each elastomer solution to the application. Our team helps define the right material, compound, and durometer, then designs custom profiles that meet functional, environmental, and regulatory requirements.

Key Characteristics

Elastomers represent a broad family of materials, each offering its own balance of flexibility, durability, and resistance to environmental stress. While their specific performance varies by formulation, most elastomers share the following key characteristics:

- Temperature Range: -60°C to 250°C depending on compound (silicone at high end)

- Chemical Resistance: Excellent against water, ozone, and many chemicals; varies by base polymer

- Elastic Recovery: Exceptional flexibility and rebound under compression or tension

- Mechanical Strength: Moderate tensile strength; customizable durometer from very soft to rigid

- Electrical Insulation: Strong dielectric performance in many silicone and EPDM grades

- Process Versatility: Customized extrusions to meet demanding applications. Options available in both sponge or dense forms

- Customization: Color-matching, pressure-sensitive adhesive, cutting, slitting, vulcanization, and other product finishings available.

Featured Materials

| Material | Key Benefit | Typical Uses |

|---|---|---|

| EPDM (Dense / Sponge) | Weather, ozone, and UV resistance | Outdoor seals, automotive tubing and seals, electrical insulation |

| Silicone (Dense / Sponge) | Extreme temperature tolerance and purity | Food-grade gaskets, medically compliant materials, high temperature applications |

| Neoprene (Dense) | Balanced chemical, oil, and weather resistance | Industrial seals, vibration isolation |

| Nitrile (Dense) | Excellent oil and fuel resistance | Automotive and hydraulic seals |

| SBR (Dense) | Economical, good abrasion resistance | General-purpose seals and gaskets |

| Polyisoprene (Sponge) | Soft, flexible, natural rubber properties | Cushioning, vibration pads |

| TPE (Thermoplastic Elastomer) | Processable like plastic, flexible like rubber | Seals and weatherstripping |

Industries and Applications

Elastomers are used wherever flexibility, sealing, and environmental resistance are critical. Pexco’s supplies materials to meet demanding needs in:

- Lighting – LED fixture gaskets, optical diffusers, lens seals, outdoor housing seals

- HVAC & Building Systems – duct and panel gaskets, thermal and acoustic insulation seals, vibration dampers, weatherstripping, and condensate management tubing

- Energy & Power Generation – turbine and solar equipment gaskets, cable and junction seals, oil and gas system tubing, outdoor insulation barriers

- Electrical & Electronics – cable insulation, connector boots, enclosure gaskets, flame-retardant barriers

- General Industrial Applications – standard seals, gaskets, vibration pads, weatherstripping, and insulation components used across equipment, enclosures, and machinery

- Medical, Life Sciences & Food Processing – pump and valve seals, diagnostic device interfaces, peristaltic pump components, sanitary gaskets, food processing and packaging seals

- Industrial & Chemical Processing – fluid transfer tubing, chemical-resistant seals, pump gaskets, tank and containment system components

- Telecom & Data Center – rack and cabinet gaskets, airflow and ingress seals, cable management profiles, weatherproof outdoor enclosures

- Water Treatment & Management – filtration seals, pump and valve gaskets, tubing for dosing and metering, UV and ozone-resistant profiles

- Aerospace & Defense – cabin and equipment seals, vibration isolators, fuel and hydraulic system gaskets, wire harness protection

- Semiconductor – wet and dry bench seals, chemical delivery tubing, wafer handling equipment components, tool interface gaskets

Pexco’s Elastomer Manufacturing Capabilities

Pexco has decades of experience producing high-quality elastomer extrusions in both dense and sponge forms. We work as a flexible manufacturing partner, offering a wide range of elastomer materials and the ability to customize profiles, shapes, and configurations to fit each customer’s application.

Our facilities are equipped for tight, repeatable extrusion control and comprehensive secondary operations, allowing us to deliver parts ready for use or assembly. From slitting and taping to vulcanization and cutting, Pexco supports customers who need consistent quality and responsive service from a trusted partner.

Capabilities Include

- Extrusion of dense and sponge elastomers across a wide durometer range

- Custom profile design and material selection support

- Secondary operations: taping, slitting, vulcanization, cutting, and packaging

- Clean, consistent production with strong in-process quality controls

- US-based manufacturing with ISO-certified facilities

The Pexco Advantage

- 30+ years of elastomer processing experience

- 2 elastomers facilities in North America

- Extensive range of elastomer and TPE materials processed annually

- Proven quality and reliability across diverse markets

Elastomer Extrusions

Request More Information

Work with a plastics partner with a deep understanding of custom elastomer extrusions.

"*" indicates required fields