Why Plastics and Elastomers Are the Backbone of Medical Tubing

Medical device innovation depends on the ability to move fluids and signals with absolute precision, often in environments that challenge even the most advanced materials. From microfluidic pumps to surgical catheters and drug delivery systems, performance plastics, especially fluoropolymers, are the backbone of modern medical tubing and components.

Their unique combination of chemical inertness, biocompatibility, purity, and processability has made plastics and elastomers the dominant material class in medical tubing and fluid handling applications. This is not a case of replacing legacy materials like metal or glass. It’s about enabling entirely new categories of medical innovation that would not be possible without advanced polymers.

Fluoropolymers in Medical Devices: Enabling Precision and Purity

Fluoropolymers such as PTFE, PVDF, and PFA have become foundational to microfluidic drug delivery, diagnostics, and minimally invasive surgical systems. Their unmatched chemical resistance, thermal stability, and biocompatibility make them ideal for fluid contact components like micropumps, valves, and precision tubing.

In particular, ultra-high purity (UHP) PFA is used in drug delivery and diagnostic applications that demand extremely low levels of extractables, leachables, and trace metals. Its inertness ensures compatibility with sensitive compounds and biologics, making it a go-to material in pharmaceutical manufacturing, lab systems, and critical patient care environments.

Tubing Systems: Why Plastics and Elastomers Are the Standard

Medical tubing must meet demanding requirements: controlled flexibility, chemical resistance, sterilization compatibility, and tight dimensional tolerances. These needs rule out materials like metal and glass for most applications. Plastics and elastomers are not just an option. They are the default accounting for the vast majority of tubing systems used across the medical industry today.

Examples of materials and their applications include:

- PVC – Flexible, clear, and widely used in IV and respiratory tubing.

- Polyurethane (PU) – Elastic and strong, ideal for catheters and pump tubing.

- TPEs – Soft-touch, kink-resistant materials for peristaltic pump systems.

- Silicone – Inert and implantable; commonly used in drains and anesthesia lines.

- Fluoropolymers – Chemically inert, ultra-smooth, and UHP-compatible used in critical delivery paths and diagnostics.

Each polymer class offers unique benefits. But collectively, they support scalable production and highly engineered system performance; attributes metals and other legacy materials simply cannot deliver.

Heat Shrink Tubing: Improving Navigation and Device Integration

One of the most advanced uses of fluoropolymers in tubing form is heat shrink tubing, which is widely used in surgical and interventional devices. These materials don’t just protect—they enhance performance:

- Low-friction surfaces support smoother insertion and withdrawal.

- Uniform shrinkage secures complex geometries and hybrid structures.

- Sterilization compatibility allows for a broad range of processing methods.

Fluoropolymer heat shrink tubing contributes to easier device navigation through the body, better procedural accuracy, and reduced tissue trauma.

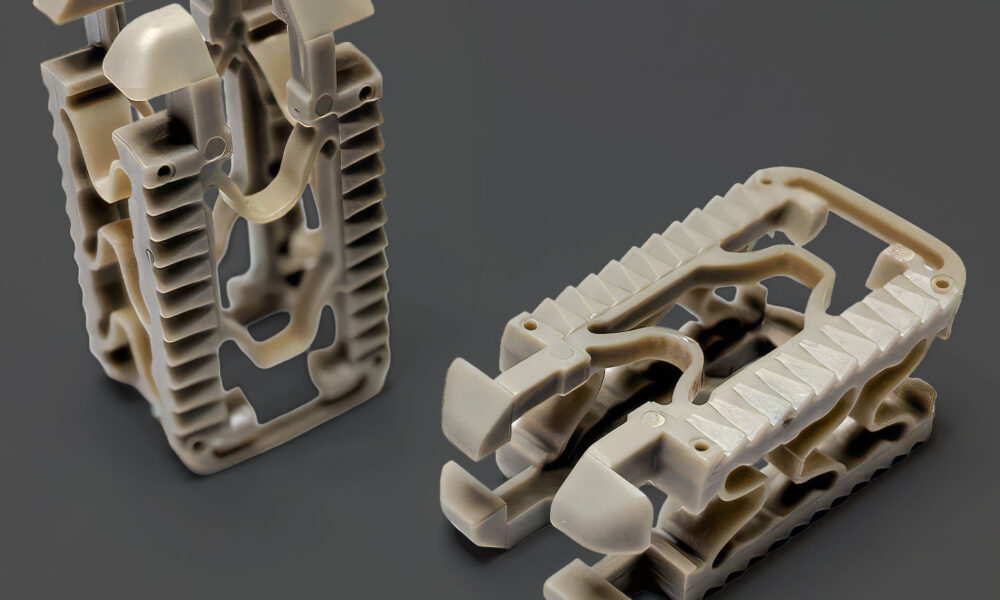

Injection Molding Fluoropolymers for Complex Components

For small, high-precision parts that tubing alone can’t support, injection molding of fluoropolymers provides a scalable solution. PFA, PVDF, and ECTFE can be molded into intricate shapes with tight tolerances and excellent repeatability. This method also enables:

- Overmolding and insert molding with hybrid materials,

- ISO 7/8 cleanroom manufacturing for sterility,

- And compatibility with multiple sterilization modalities (EtO, gamma, steam, dry heat)

Compared to machining, which is limited in design flexibility and throughput, molding opens the door to fully integrated device systems that reduce part count and improve reliability.

Material Surface Properties That Improve Performance

Plastics meet bulk property requirements, and they enable surface-level engineering as well. Internal smoothness ensures laminar flow, reduces clotting and bacterial adhesion, and improves drug delivery precision. In some cases, additives or coatings can be used to impart antimicrobial or antithrombogenic properties to the tubing surface.

These enhancements are especially important in long-term vascular access, dialysis, and infusion therapies where tubing interacts directly with the body over extended periods

Sterilization Compatibility and Single-Use Efficiency

Modern healthcare systems increasingly rely on sterile, single-use components to improve patient safety and reduce reprocessing burdens. Plastics and fluoropolymers support this model with:

- Predictable behavior under sterilization (gamma, EtO, e-beam, steam),

- Defined shelf life and packaging compatibility, and

- Resilience to multiple sterilization cycles for components requiring reuse.

Looking Ahead: Engineering the Future of Medicine

As medical devices evolve toward greater precision, miniaturization, and integration, the role of performance plastics will only deepen. Fluoropolymers, in particular, are poised to drive the next generation of life science technologies, enabling everything from wearable drug pumps to integrated sensor assemblies.

For design engineers, process developers, and materials scientists, performance plastics are more than structural materials. They are engineering platforms that support functional design, regulatory compliance, and clinical performance. And in the world of medical tubing and microfluidics, they remain the unsung heroes behind many of healthcare’s most advanced capabilities.

Designing A Medical Device Component?

Our experts can help you navigate material selection, testing requirements, and manufacturing considerations.

Contact Us – https://www.pexco.com/contact-us/