Our Products

Our Brands

Markets

Capabilities

About Pexco

Lighting Components

Pexco specializes in creating high-quality, engineered solutions that help bring your lighting products to life. Our comprehensive range of lighting components is designed to meet the diverse needs of the lighting industry, ensuring performance, durability, and aesthetic appeal.

View Our Lighting Gallery

Welcome to our Lighting Gallery, designed to showcase just a sampling of the thousands of components created for our customers through the years. Take a quick scroll through each photo carousel to better understand how Pexco’s extensive Lighting capabilities can help your next idea to take shape. We hope you are as inspired as we are by the beauty, creativity, and functionality achieved when partnering together to build a premier product. Collaborate with Team Pexco to create the perfect solution for your next project.

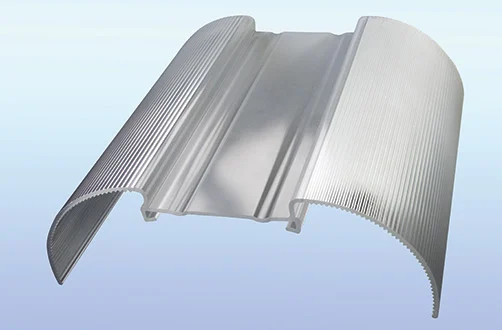

Mono-Extrusions

Co-Extrusions & Tri-Extrusions

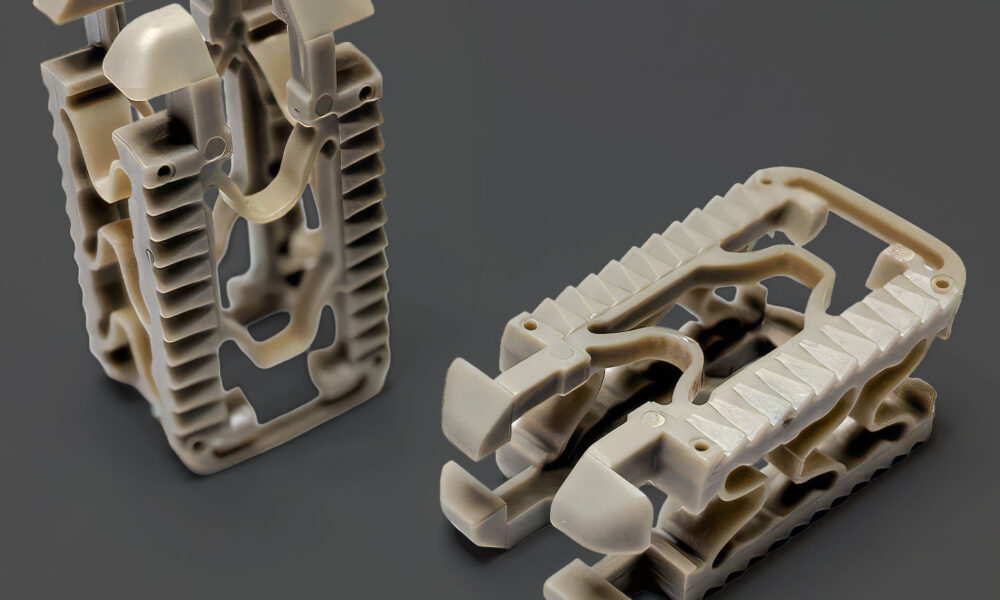

Fabrication/Value Add Services

Custom Lighting Components

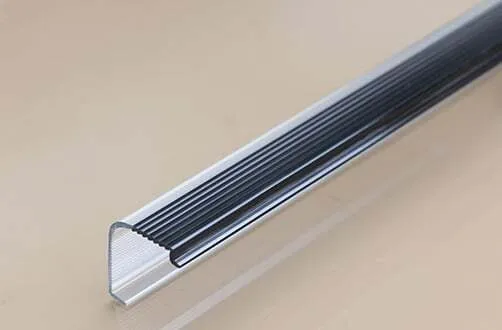

Pexco, North America’s foremost expert in extruded acrylic and polycarbonate lighting components, specializes in custom extruded diffusers and lenses. With decades of experience and proprietary material blends, we not only help lighting manufacturers meet or exceed lumen output requirements but also ensure optimal diffusion, light distribution, and aesthetic differentiation.

Passionate about exceeding customer expectations, we understand the dual needs of high-performing components for OEMs and the end users’ demand for fixtures that provide the perfect ambiance and differentiation. By offering innovative custom solutions, Pexco helps customers excel and grow their market share in the lighting industry.

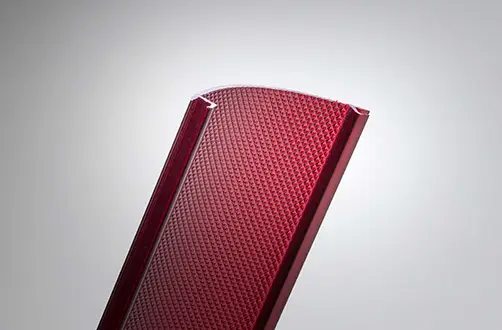

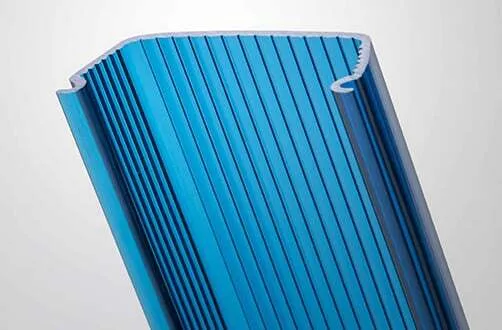

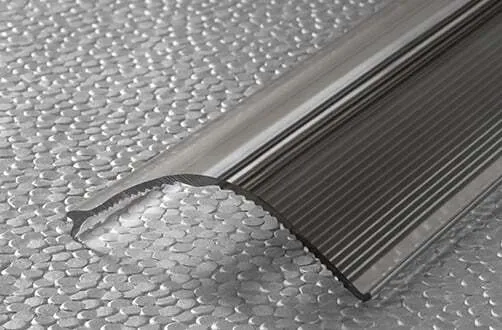

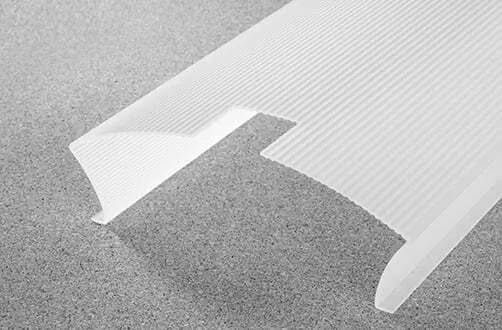

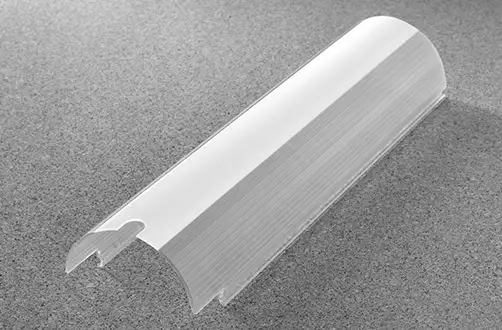

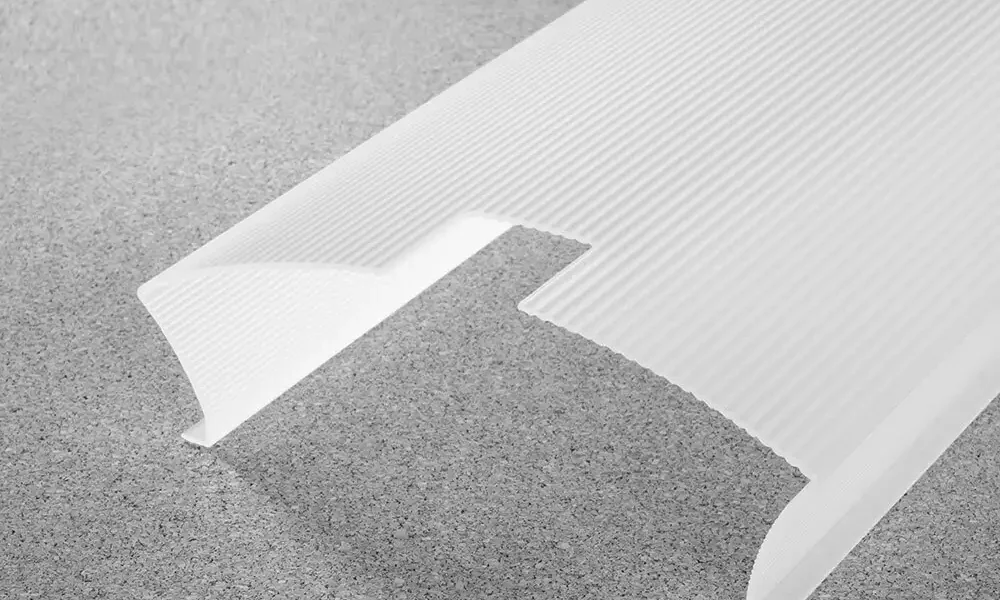

Lenses

Precision engineered lenses designed to direct, focus and control light into specific patterns, increasing intensity, enhancing illumination efficiency and reducing glare.

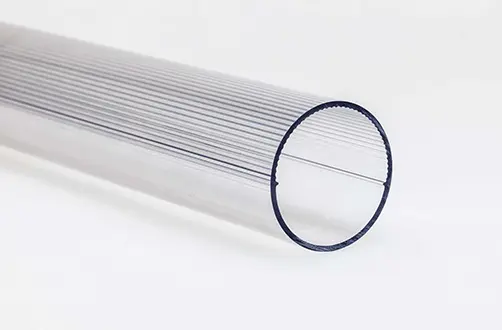

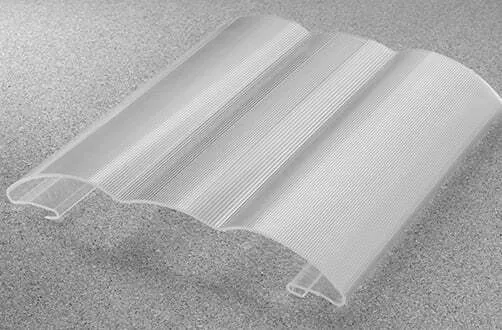

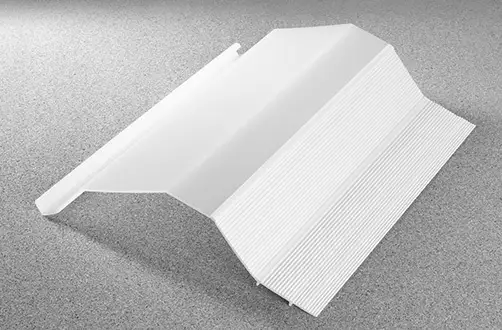

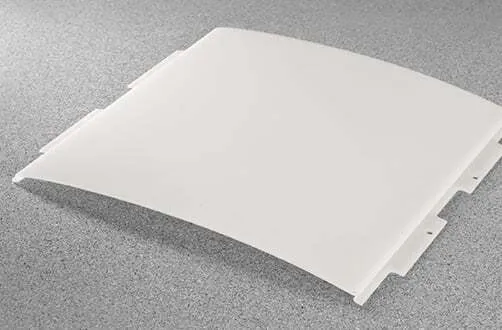

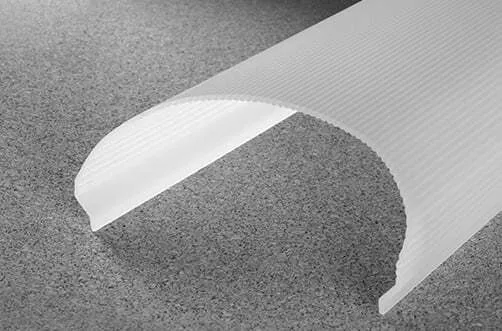

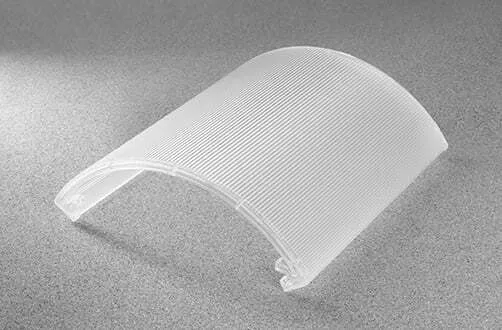

Diffusers

Expertly crafted diffusers engineered to scatter, spread and soften light, ensuring the light spreads uniformly and efficiently.

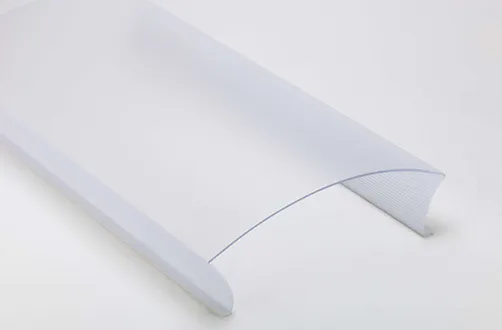

LED Lens Covers

Engineered for demanding environments, high-quality optical lens covers protect LEDs from dust, moisture, and mechanical impact – ensuring reliable operation even under harsh conditions. Precision optics enhance light output and distribution, delivering brighter, more efficient illumination.

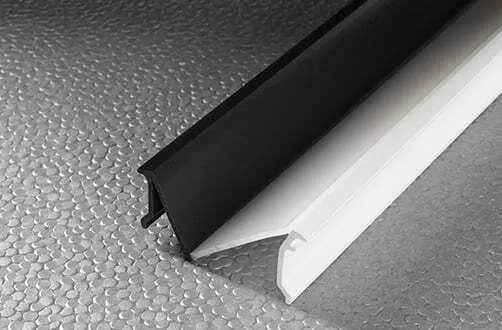

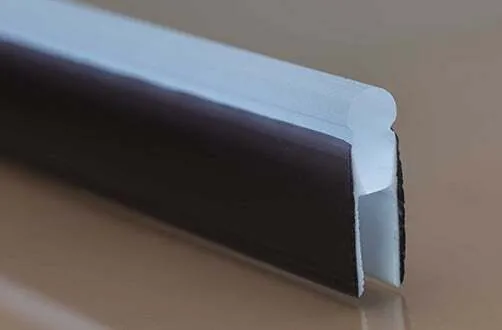

Silicone Seals

High-performance silicone seals designed to block moisture and dust, protecting lighting assemblies from harsh environment while preserving optical clarity and system integrity.

Lenses and Diffusers

Optimize your linear light fixture by partnering with Pexco in the lens or diffuser development. Pexco has generations of experience in supporting Lighting OEMs to develop new and innovative fixtures which deliver the perfect combination of light distribution, diffusion, and lumen output.

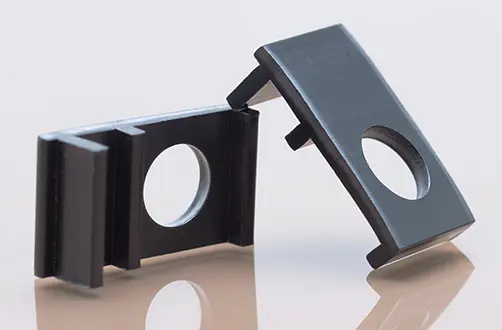

Have you ever worried about the lens you design falling out of the fixture?

It’s a big concern for many engineers in the lighting industry. Rest assured, Pexco provides part design guidance to help our customers design a sturdy and elegant lens assembly to prevent such an occurrence.

For medical or outdoor IP rated fixtures, Pexco is experienced with co-extruding flexible seals directly into an acrylic or polycarbonate lens.

Pexco manufactures linear extruded lighting components up to 12 feet in length, for use in nearly all indoor ambient, commercial, medical, and hospitality applications. These include but not limited to fixtures such as troffers, wraps, stairwells, strips, recessed, suspended, wall mounts, edge lighting, retrofits, undercabinet, garage, and vandal resistant.

Silicone Seals

Pexco Silicone Seals deliver high-quality, durable silicone sealing solutions ideal for demanding applications in industries like commercial & outdoor lighting and electronics where moisture, dust and dirt can cause contamination. Engineered for superior performance and resistance to extreme conditions, Pexco Silicone Seals provide reliable, long-lasting protection to help enhance and extend product life.

Lighting Seals

- RPVC

- FPVC

- TPU

- TPE

- Silicone

- EPDM

Applications

- Commercial

- Architectural

- Medical

Lighting Capabilities

Lighting OEMs face a number of challenges with changing regulations and competitive pressure. Pexco clearly understands that technical expertise, speed in engineering development, product quality, service, delivery, and reducing overall cost are essential elements to helping our customers be successful.

Offering industrial lighting design and services, we have the capability to produce lenses with widths ranging from 1/3” to 23” and up to 16 feet long. We can supply surface patterns such as customized linear prisms, or rolled on diamond pattern prisms. We are superbly skilled with complex hook and leg designs, co-extrusions, and custom colors.

Pexco engineers help guide our customers through the entire design process.When it comes to choosing the optimal material blend and achieving just the right “hook to hook” dimension for a perfect “squeeze and release” or “snap over” fit, Pexco has the experience and knowledge to provide quick solutions.

If you need help with your lighting component design, our engineers, sales team and project managers are available to help you optimize your material blend, finalize your profile shape, add features, specify tolerances and design linear prisms. Feel free to share your design with Pexco and get one-on-one technical design support.

We are also available to educate and train your team in extrusion design or processing with a hands-on seminar. Our mission is to make our customers’ projects easy and successful.

The name Pexco stands for Plastic Extrusion Company. Plastic extrusion is our #1 core competency. We have multiple extrusion and co-extrusion machines within our company and many of those are dedicated to acrylic and polycarbonate components for the lighting industry. Lighting OEMs have been relying on Pexco for their customized linear lighting lenses and diffusers since the 1970s.

Pexco’s expertise in lighting starts with having tremendous knowledge and experience extruding acrylic and polycarbonate material blends. With gravimetric blenders capable of blending 4 resins at one time, customers receive the perfect material formula with the right amount of diffusion, impact modifier, and color at a competitive cost. We have built our capabilities around customers’ needs by investing in manufacturing floor space, machinery, technology, fabrication, and service.

Pexco’s expertise in lighting starts with having tremendous knowledge and experience extruding acrylic and polycarbonate material blends. With gravimetric blenders capable of blending 4 resins at one time, customers receive the perfect material formula with the right amount of diffusion, impact modifier, and color at a competitive cost. We have built our capabilities around customers’ needs by investing in manufacturing floor space, machinery, technology, fabrication, and service.

Looking for an extrusion seminar to help educate your engineers? Pexco offers educational presentations about the extrusion process and designing parts for extrusion.

Speed to market is a necessity when it comes to launching lighting products successfully. Pexco assigns a Program Manager to guide our APQP process and keep everyone on track.

Pexco begins every project with an APQP (Advanced Product Quality Planning) meeting with our customer. Getting the details ironed out before we cut a die is essential to eliminating waste later. Pexco also provides FAIR (First Article Inspection reports) with initial samples, and PPAPs when requested. Pexco develops a control plan for each project and uses calibrated measuring equipment to monitor quality throughout production. Pexco is ISO 9001: 2015 certified.

One of the biggest challenges our customers face is to be able to quick ship an order within a few days of receipt. Space to hold inventory is often difficult for our customers, so Pexco offers stocking programs on certain items to allow next day shipments from our facility.

Lighting Materials Expertise

One of the many benefits of working with Pexco is that we are highly experienced with an extensive variety of raw materials. Once you help us to understand your product application, we will support you with a material recommendation.

Sometimes our customers know in advance the exact material needed for their product. At other times, the product design requires a custom-blended mix of multiple resins and additives to provide the optimal combination of light transmission and diffusion. Pexco stocks a wide range of reliable, high-quality acrylic and polycarbonate base resins, along with high-performing LED diffusive and colored additives, to give our customers the advantage of volume resin pricing with little to no lead time.

Pexco is also experienced with flexible and rigid PVC, reflective ABS or PC/ABS, and other resins used in lighting applications. For more information on developing the perfect material blend for your project, feel free to peruse some of our house materials, or call us today.

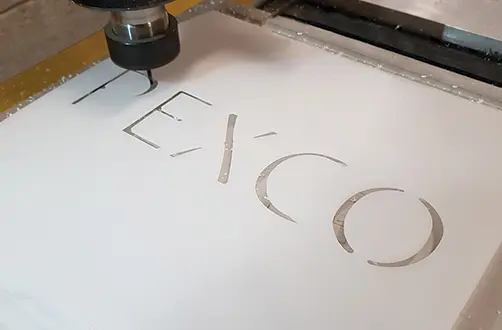

Pexco continues to outperform the extrusion market with our short lead times, scalability, material solutions, and price competitiveness. Pexco has built our manufacturing expertise to provide our customers with LED lighitng lenses and extrusion solutions for industrial and commercial applications that include: co-extrusion, CNC routing, precision cutting, tight unusual angle cuts, ultrasonic welding, and various forms of assembly. Pexco manufactures extruded lighting components such as LED lighting lenses in the USA and Mexico.